Weak base ternary composite reservoir oil displacement composition with formulated surfactant and application thereof

A technology of surfactant and ternary compounding, which is applied in the direction of drilling composition, production fluid, wellbore/well components, etc., can solve the difficulty of interfacial tension between a single surfactant and crude oil, and affect the injection process and injection of the composite system Time rate, fouling at the injection end, etc., to achieve the effect of solving the lifting system problem, low possibility, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Carry out the experiment of this embodiment according to the following operations:

[0049] 1 Measure the interfacial tension of the uniform composite system prepared on the same day. The prepared composite system must be capable of ultra-low interfacial tension on the order of 10-3mN / m with crude oil, and the measured interfacial tension is taken as the 1-day interfacial tension of the system.

[0050] 2 Put the compound system prepared into the colorimetric tube. During the filling process, the colorimetric tube should be filled as much as possible to reduce the residual air in the colorimetric tube, and the colorimetric tube should be sealed.

[0051] 3 Put the sealed colorimetric tube in a constant temperature box at 45°C. After 90 days, the interfacial tension between the composite system and crude oil was measured as the 90-day interfacial tension of the system.

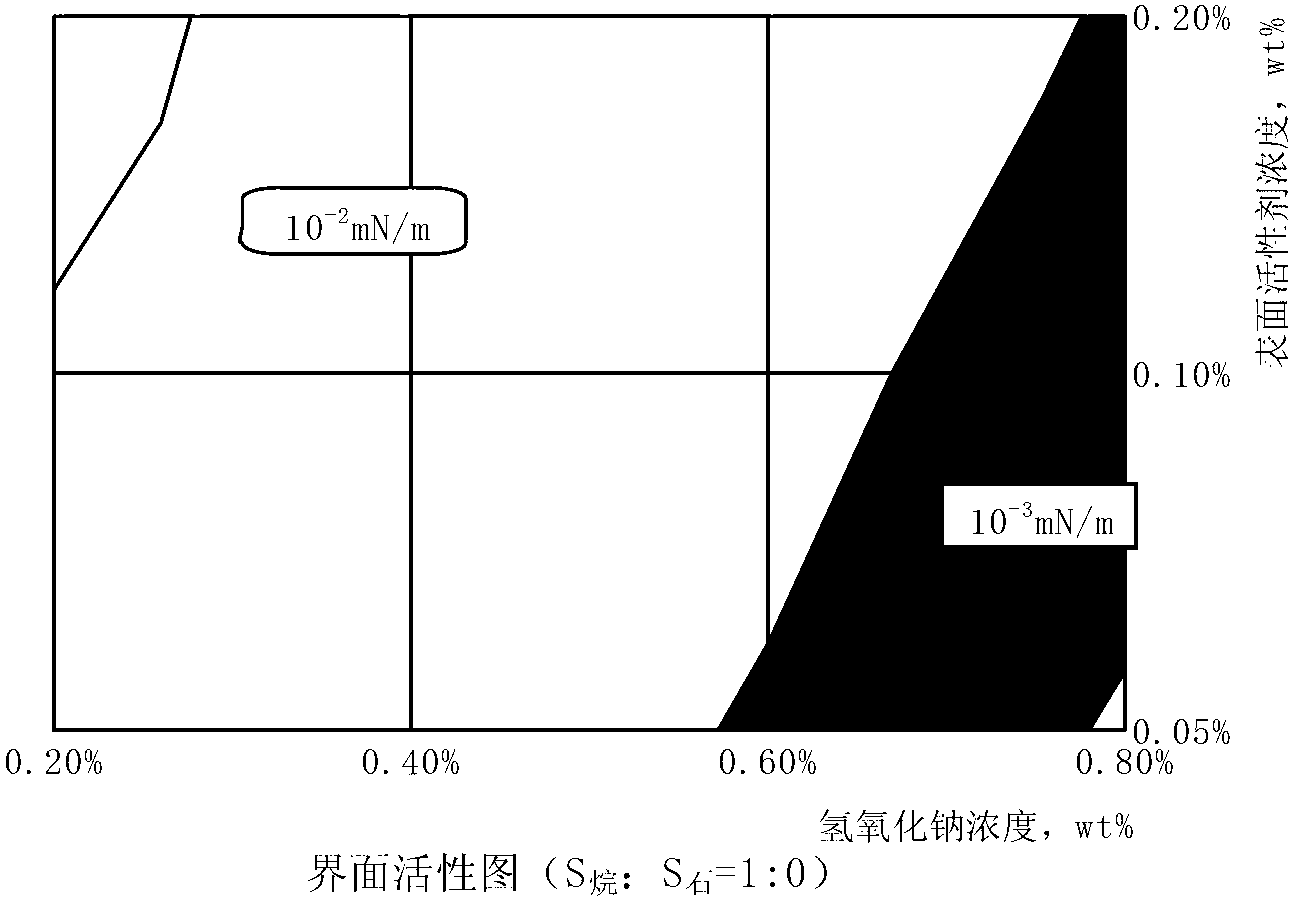

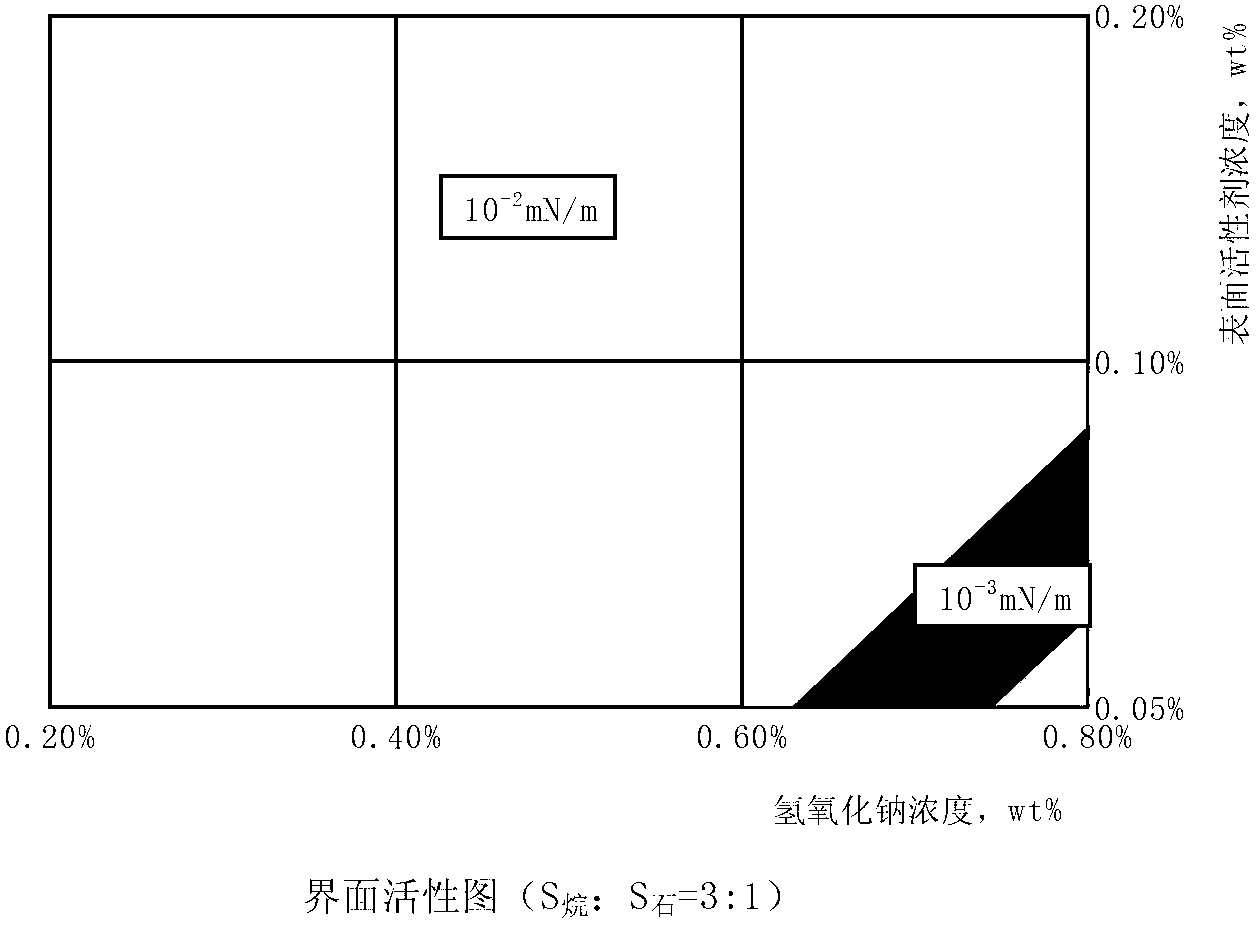

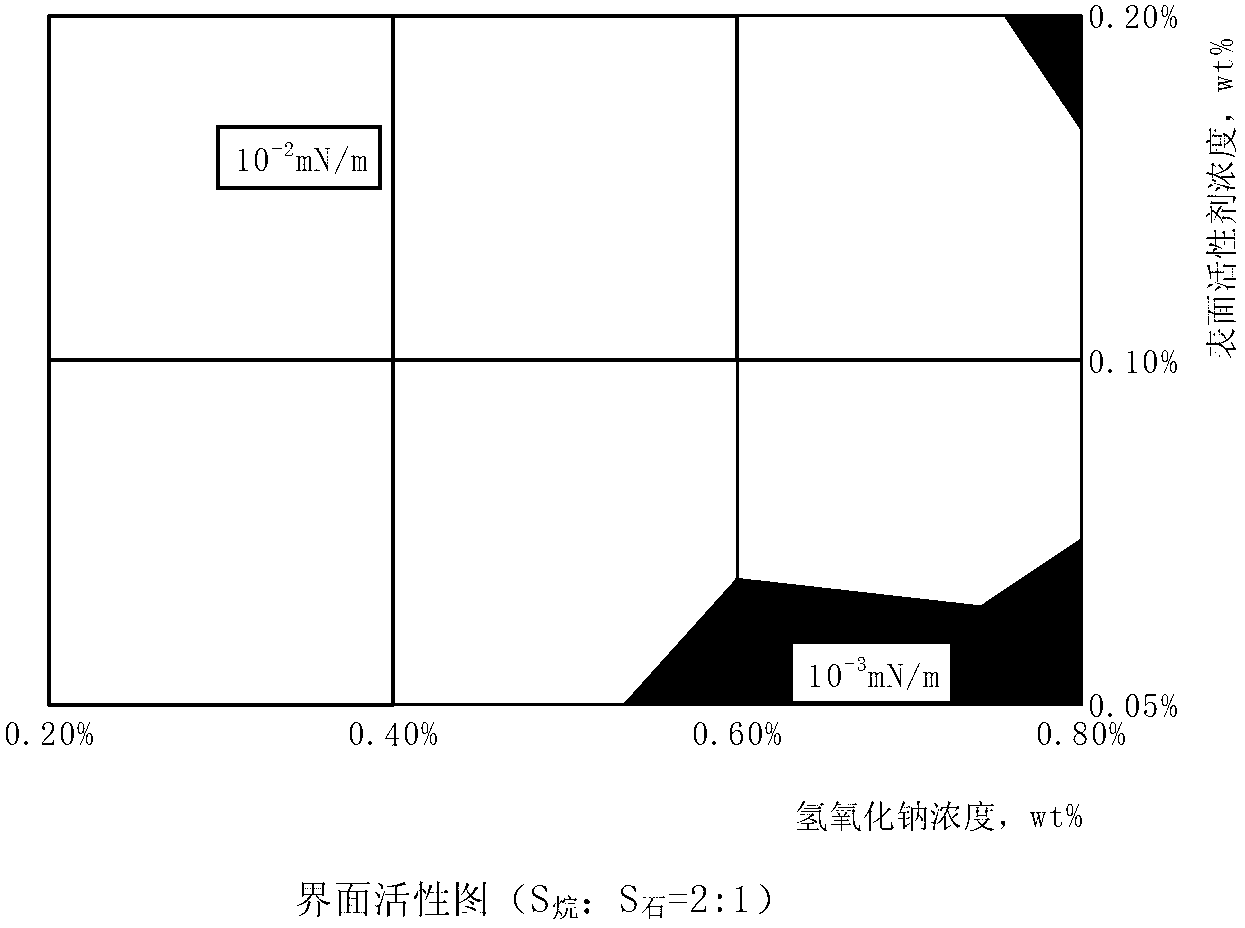

[0052] Figure 14 , Figure 15 It shows the stability and activity of the compound surfactant oi...

Embodiment 2

[0054] In this example, the emulsification performance of the oil displacement system of the present invention is investigated through an emulsification experiment. Specific emulsification experiment:

[0055] 1 Determine the concentration point of the composite system (active agent, alkali) used in the emulsification experiment according to the interfacial tension performance of the composite system.

[0056] 2 According to the oil-water volume ratio of 1:1, add a certain volume of V0 composite system and crude oil into the stoppered measuring cylinder, and place it in a 45°C constant temperature box, and let it stand for 1 hour.

[0057] 3 Use a homogenizer to stir at 11000rpm for 1min, stir the composite system and crude oil evenly, then place it in a constant temperature box at 45°C, observe and record the volume change of the water phase until the volume of the water phase no longer changes, Record the final aqueous phase volume V1, and record the experimental phenomena ...

Embodiment 3

[0062] The core flooding experiment was carried out for the compound surfactant system of sodium carbonate + salt, and the specific experimental scheme is as follows:

[0063] 1. Water flooding, the water content reaches more than 98%;

[0064] 2. The front polymer slug is 0.1PV, P: 1600mg / L, and the dirt is mixed with the dirt;

[0065] 3. Ternary system of ternary compound surfactant 0.3PV (see the table below for the formula);

[0066] 4. The follow-up polymer protection slug is 0.2PV, P: 1600mg / L, and the dirt is mixed with the dirt;

[0067] 5. Subsequent water flooding, the water content reaches more than 98%.

[0068] Surfactant ratio is S 石 :S 重 = 3:1 sodium carbonate + sodium chloride compound system flooding experimental data

[0069]

[0070] It can be seen that the three-component composite oil flooding composition of the present invention drives oil, and each component interacts and contributes synergistically, and finally keeps the performance of the syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com