Pile cap former, pile head treatment and pile cap construction method

A former and pile cap technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as irregular operation of construction personnel, irregular shape of cylindrical soil molds, uncontrollable construction quality, etc. The method is flexible, the construction process is easy to control, and the effect of the construction process is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

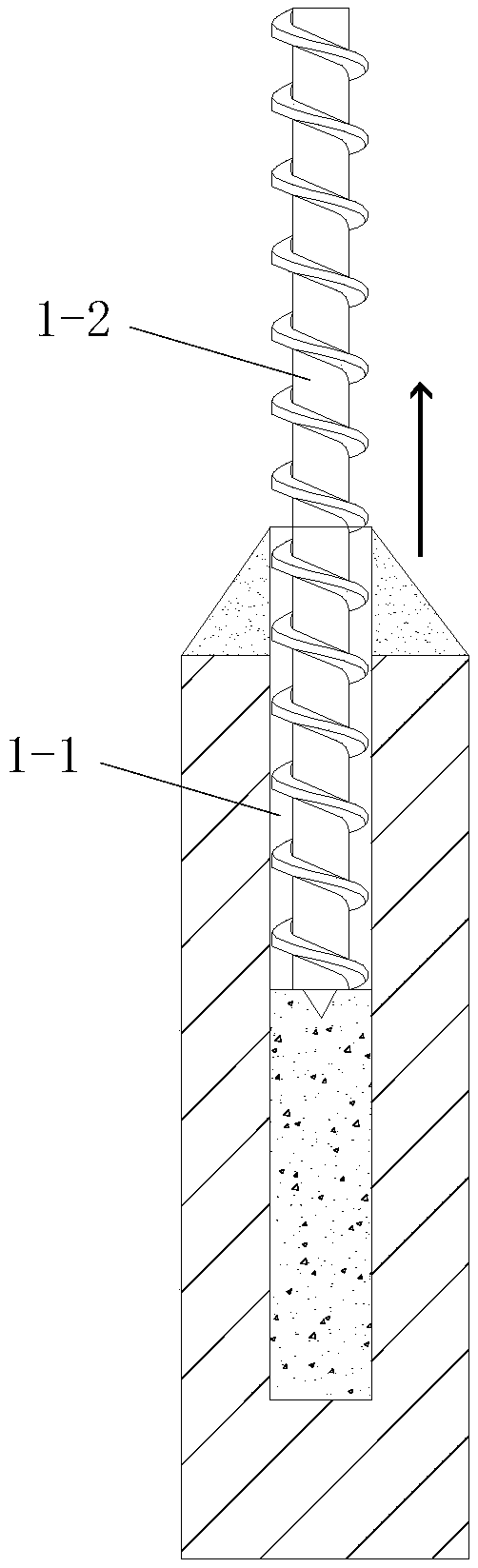

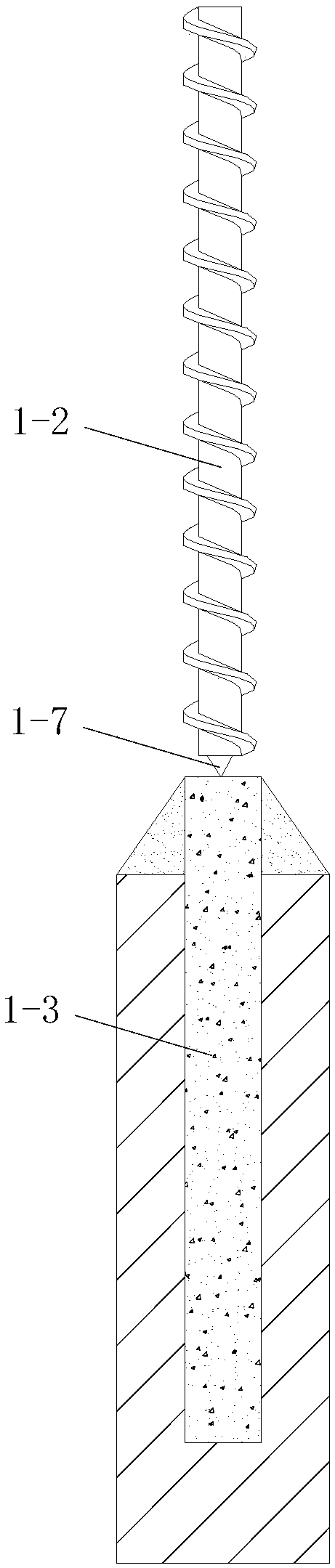

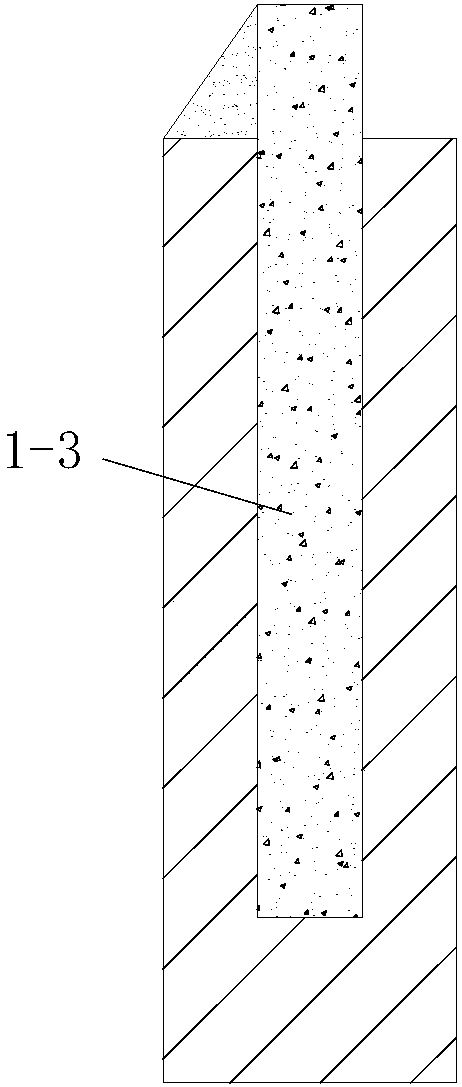

[0066] like figure 1 , figure 2 A pile cap former shown includes a pile cap forming drill bit for hole-forming pile cap 2 to be constructed and a rotary driving device that drives the pile cap forming drill bit to continuously rotate, and the rotary driving device is located at the Above the pile cap forming drill bit, the pile cap forming drill bit is in transmission connection with the rotary drive device; Figure 5 and Image 6 , the pile cap 2 to be constructed comprises an upper pile cap section and a lower pile cap section, the upper pile cap section is a truncated cone, the lower pile cap section is a truncated cone, and the diameter of the lower pile cap section is determined by the upper Decrease gradually to the bottom and the diameter of its upper end is identical with the diameter of described upper pile cap section; The pile cap 2 that needs to be constructed is the pile cap of cast-in-place pile, and the diameter of described cast-in-situ pile is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com