Multi-layer oil guide clapboard of hydraulic oil press

A technology of hydraulic oil extraction and partitions, which is applied to presses, manufacturing tools, etc., which can solve the problems of slow oil output, no oil coming out of oil cakes, and low output, and achieve fast oil output, high oil output rate, The effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

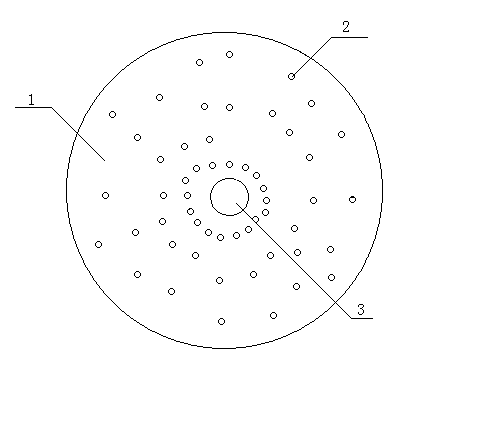

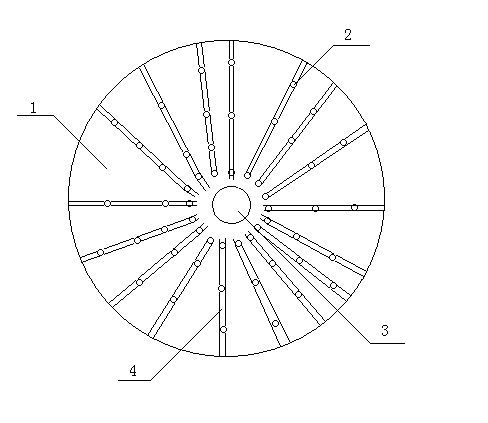

Embodiment 1

[0019] A multi-layer oil-guiding baffle for a hydraulic oil press according to the present invention is a groove on one side of the baffle 1 with a diameter of 100 mm and a thickness of 1 mm, which is connected with the oil outlet holes 2 radially from the center of the baffle 1 to the edge and leads to the edge of the oil cake. There are 16 oil guide grooves 4 with a depth of 0.5 mm and a groove width of 1 mm, which are oil passages. Drill from the center to the edge along each oil guide groove 4 on the separator 1 6 diameter 0.2 mm oil hole 2. When in use, the side of each layer of partitions 1 that does not open the oil passage faces the oil cake, and two partitions 1 are placed on the same position and one layer at the same time, and a layer of steel wire mesh is placed in the center of the two partitions 1. The rest of the operation is the same as that of the original hydraulic press. The oil machine uses the same. When the oil press presses down, the oil squeezed ou...

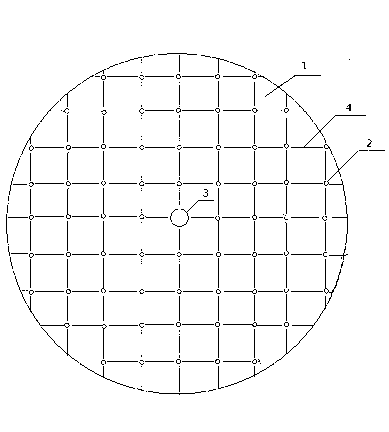

Embodiment 2

[0021] A kind of multi-layer oil-guiding separator for a hydraulic oil press of the present invention is a groove with a depth of 1.5mm and a groove width of 2mm that is parallel to the center line of the separator 1 and communicates with the oil outlet 2 on one side of the separator 1 with a diameter of 1000 mm and a thickness of 3 mm. There are 11 oil guide grooves 4 in total, i.e. oil passages; 6-50 diameter 3mm oil outlet holes 2 are drilled in each oil guide groove 4 on the dividing plate 1. When in use, the side of each layer of partitions 1 without the oil guide groove 4 is facing the oil cake. Two partitions 1 are placed on the same position and one layer at the same time, and a layer of steel wire mesh is placed in the center of the two partitions 1. The rest of the operation is the same as that of the original hydraulic oil press. The machine uses the same. When the oil extractor rod is pressed downward, the oil extracted from the oil plant will seep out along the ed...

Embodiment 3

[0023] A multi-layer oil-conducting separator for a hydraulic oil press of the present invention is formed on one side of the separator 1 with a diameter of 2000 mm and a thickness of 5. There are 11 connected oil guide grooves 4 with a depth of 3mm and a width of 3mm respectively, that is, oil passages. Drill 6-50 oil outlet holes 2 with a diameter of 5mm in each oil guide groove 4 on the separator 1. When in use, the side of each layer of separator 1 that does not open the oil passage faces the oil cake, and the same position and the same layer are placed at the same time Two partitions, a layer of steel wire mesh is placed between the two partitions 1, and the rest of the operations are the same as those used in the original hydraulic oil press. When the oil extractor rod is pressed downward, the oil extracted from the oil plant will seep out along the edge of the partition, and the oil in the center of the partition 1 will pass through the filter cloth or cotton cloth and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com