Fast oiling mechanism for hydraulic locking mechanical arm

A technology of oil injection mechanism and mechanical arm, which is applied in the direction of mechanical equipment, fluid pressure actuation device, fluid pressure actuation system components, etc. It can solve the problems of excessive, complicated steps, and non-quantified oil injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

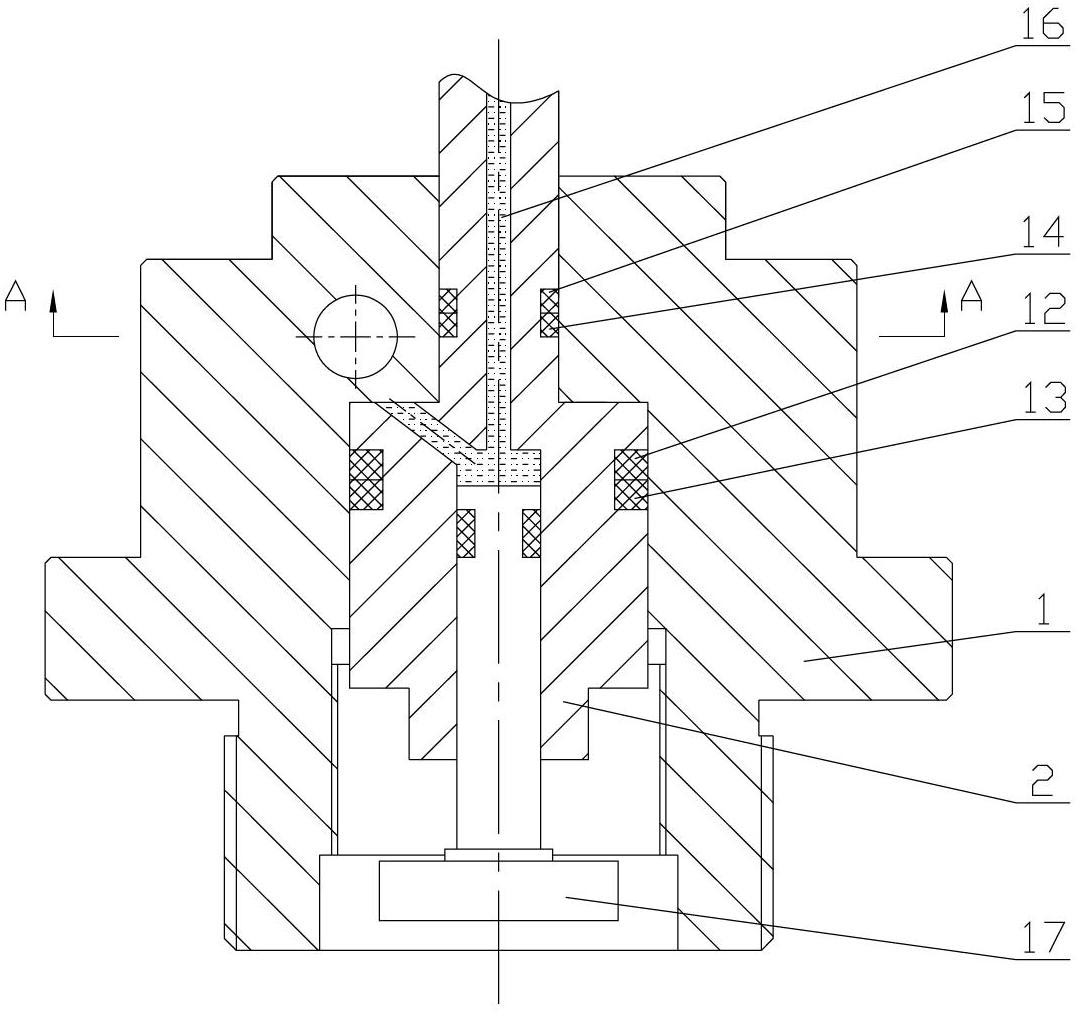

[0024] Such as figure 1 As shown, including the hydraulic source section, the oil injection module and the isolation module.

[0025] The hydraulic source part includes a hydraulic source housing 1, a hydraulic source piston 17, and a first joint shaft 2 that is in clearance fit with the hydraulic source housing, and a hydraulic oil circuit communicated with the first joint shaft 2 and the hydraulic source housing 1 is opened. 16. Through the up and down movement of the hydraulic source piston 17, the pressure of the hydraulic oil circuit 16 can be adjusted to realize the locking and releasing of the joints.

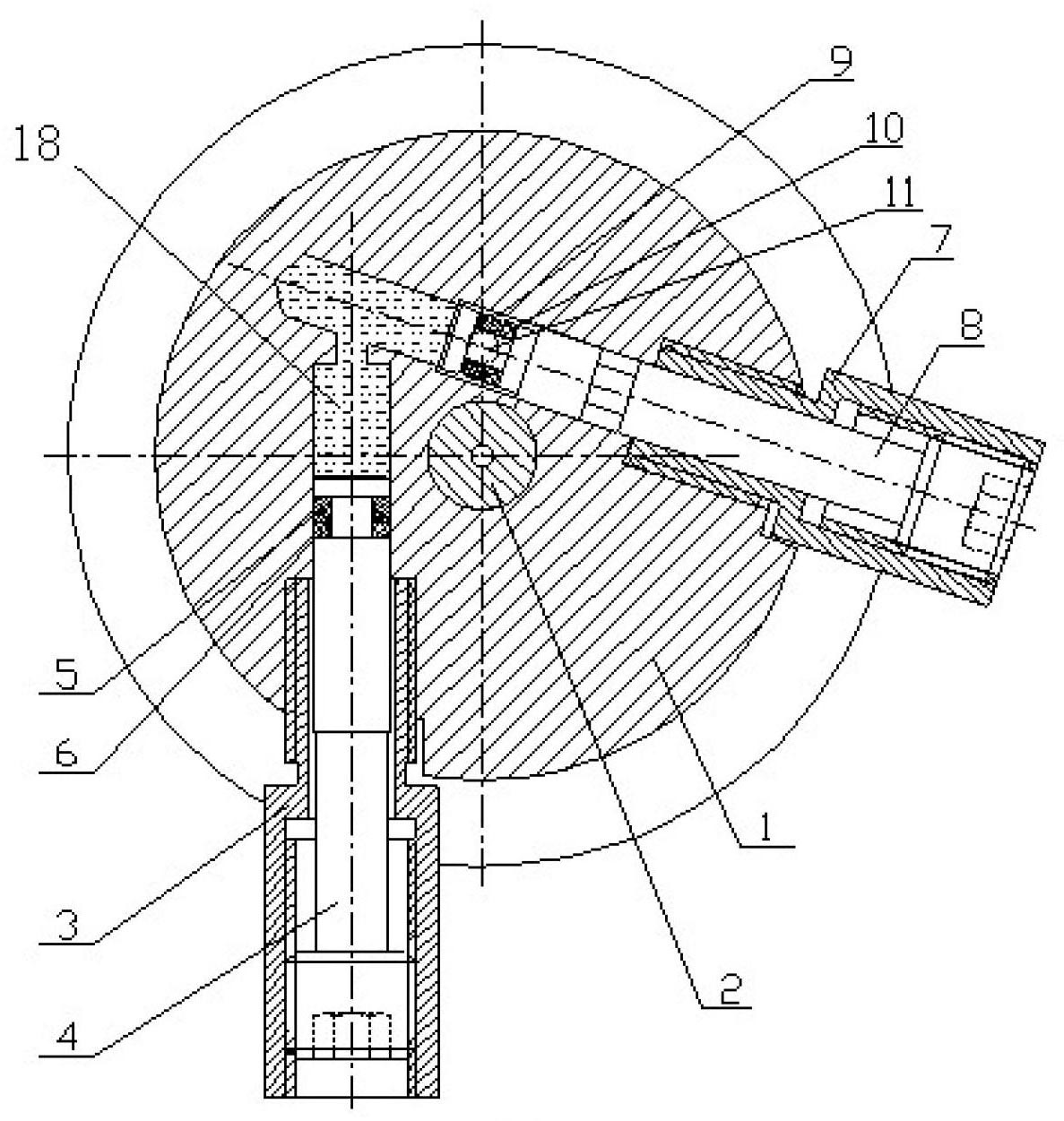

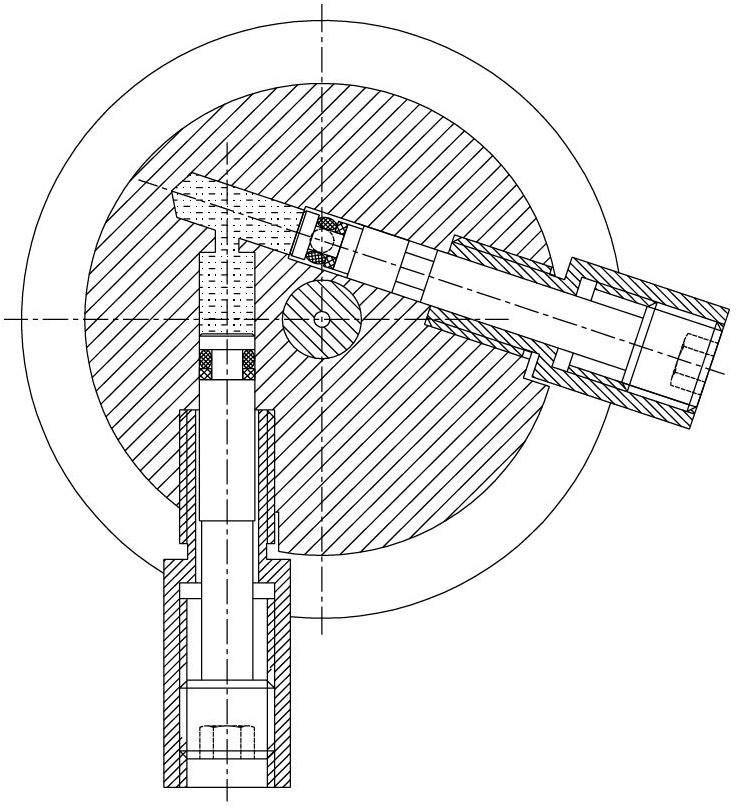

[0026] Such as figure 2 As shown, the hydraulic source casing 1 is fixed on the bottom of the mechanical arm through threads, and two stepped holes are opened on the side thereof to connect with the oil injection module and the partition module. The inner ends of the oil injection module and the partition module are provided with a connected oil injection chamber 18 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com