A kind of bamboo-based railway box car lining board and its manufacturing method

A technology for railway boxcars and inner lining boards, which is applied in the directions of manufacturing tools, chemical instruments and methods, wood-layered products, etc. Elasticity, good aesthetics, small water expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

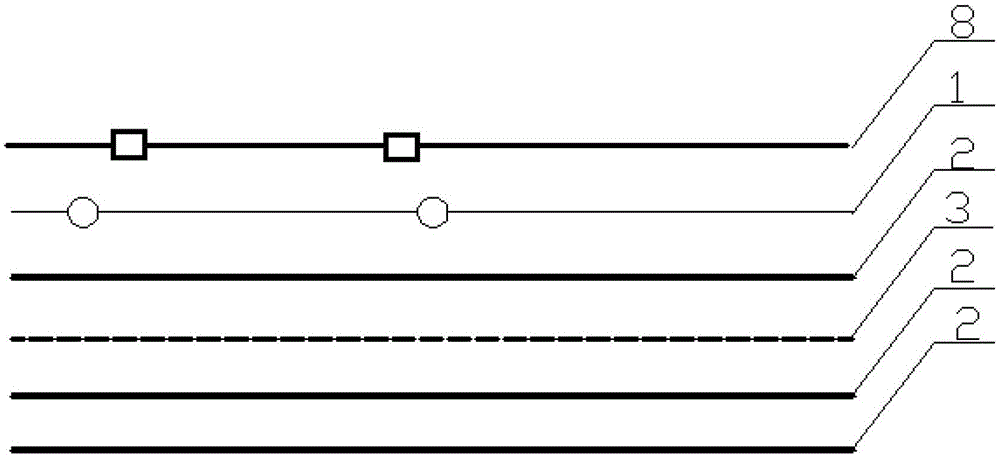

[0032] figure 1 , the structure of a bamboo-based railway box car liner is that the surface layer is a layer of fire-resistant board 8, and the bottom layer is a bamboo-based panel coated with urea-formaldehyde glue added with white latex. The structure of the bamboo-based panel is that the surface layer is a layer. A layer of bamboo mat 1 impregnated with phenolic glue and dried at low temperature, the lower layer is a layer of vertical grain bamboo curtain 2 impregnated with phenolic glue and dried at low temperature, the thickness of which is 0.8-1.5mm; Low-temperature-dried transverse-textured bamboo curtain 3, the thickness of which is 0.8-1.5 mm; and then down to two layers of transverse-grained bamboo curtain 2 impregnated with phenolic glue and dried at low temperature.

[0033] The manufacturing method is as follows:

[0034] a. Longitudinal texture bamboo curtain 2, horizontal texture bamboo curtain 3, bamboo mat 1, the thickness of which is 0.8-1.5mm; sorting and s...

Embodiment 2

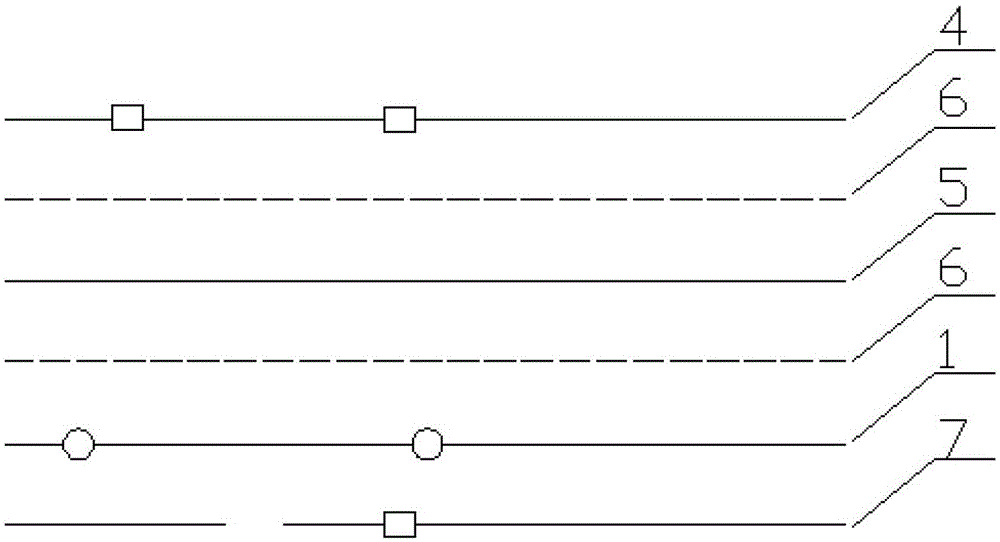

[0039] figure 2 , a bamboo-based railway boxcar inner liner, the outer layer is the first melamine impregnated paper 4 impregnated with phenolic glue and dried at low temperature, the lower layer is a horizontal textured wood veneer 6 coated with phenolic glue, and then downwards is The longitudinal texture wooden veneer 5 coated with phenolic glue, the next layer is a horizontal textured wooden veneer 6, and the next layer is a bamboo mat 1 impregnated with phenolic glue and dried at low temperature, and the next layer is the second melamine Impregnated paper7.

[0040] The manufacturing method is as follows:

[0041] a. Sorting and sorting the longitudinal grain wooden veneer 5, the transverse grain wooden veneer 6 and the bamboo mat 1, drying the longitudinal grain wooden veneer 5 and the transverse grain wooden veneer 6 until the moisture content is below 8%, and coating both sides with phenolic Glue; Bamboo mat 1 is dried to a water content below 12%, impregnated with ...

Embodiment 3

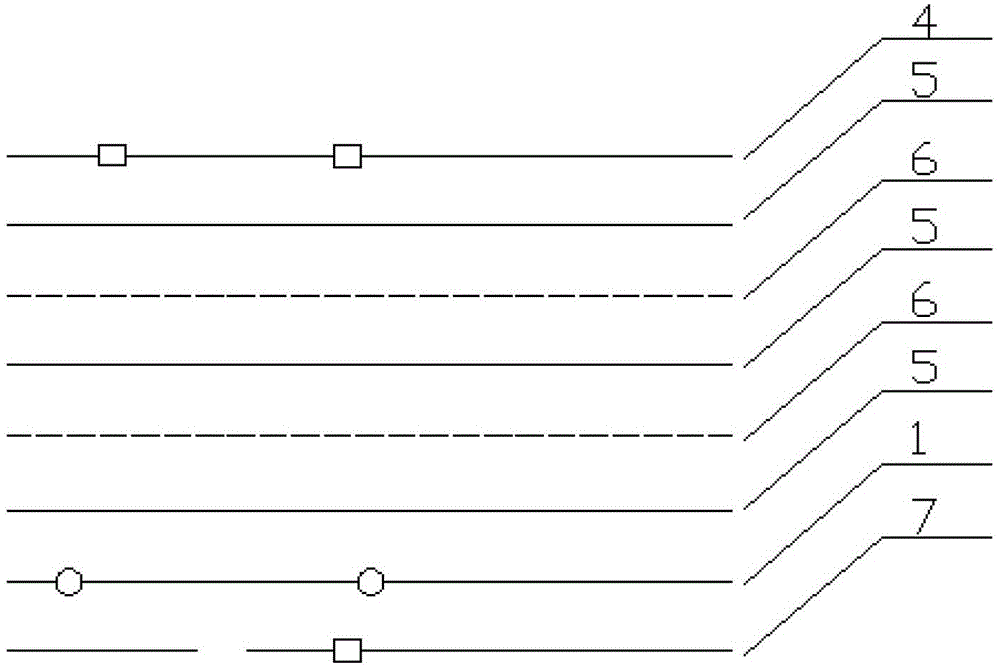

[0044] image 3 , a bamboo-based railway boxcar inner liner, the outer layer is the first melamine-impregnated paper 4 impregnated with phenolic glue and dried at low temperature, the bottom layer is a longitudinal grain wood veneer 5 coated with phenolic glue, and then downwards is The horizontal texture wooden veneer 6 coated with phenolic glue, then downwards is the longitudinal textured wooden veneer 5 coated with phenolic glue, and then the horizontal textured wooden veneer 6 coated with phenolic glue for the next layer, and then downwards The next layer is the vertical grain wood veneer 5 coated with phenolic glue, and then down is a layer of bamboo mat 1 impregnated with phenolic glue and dried at low temperature, and then down is a second layer of melamine-impregnated paper 7.

[0045] The manufacturing method is as follows:

[0046] a. Wood veneer 5 with longitudinal grain, wood veneer 6 with transverse grain, bamboo mat 1 sorting and sorting, wood veneer 5 with long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com