Cutter system of plate casting machine

A technology of caster and cutter, applied in shearing devices, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as grid curling and even deformation, and overheating of cutters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

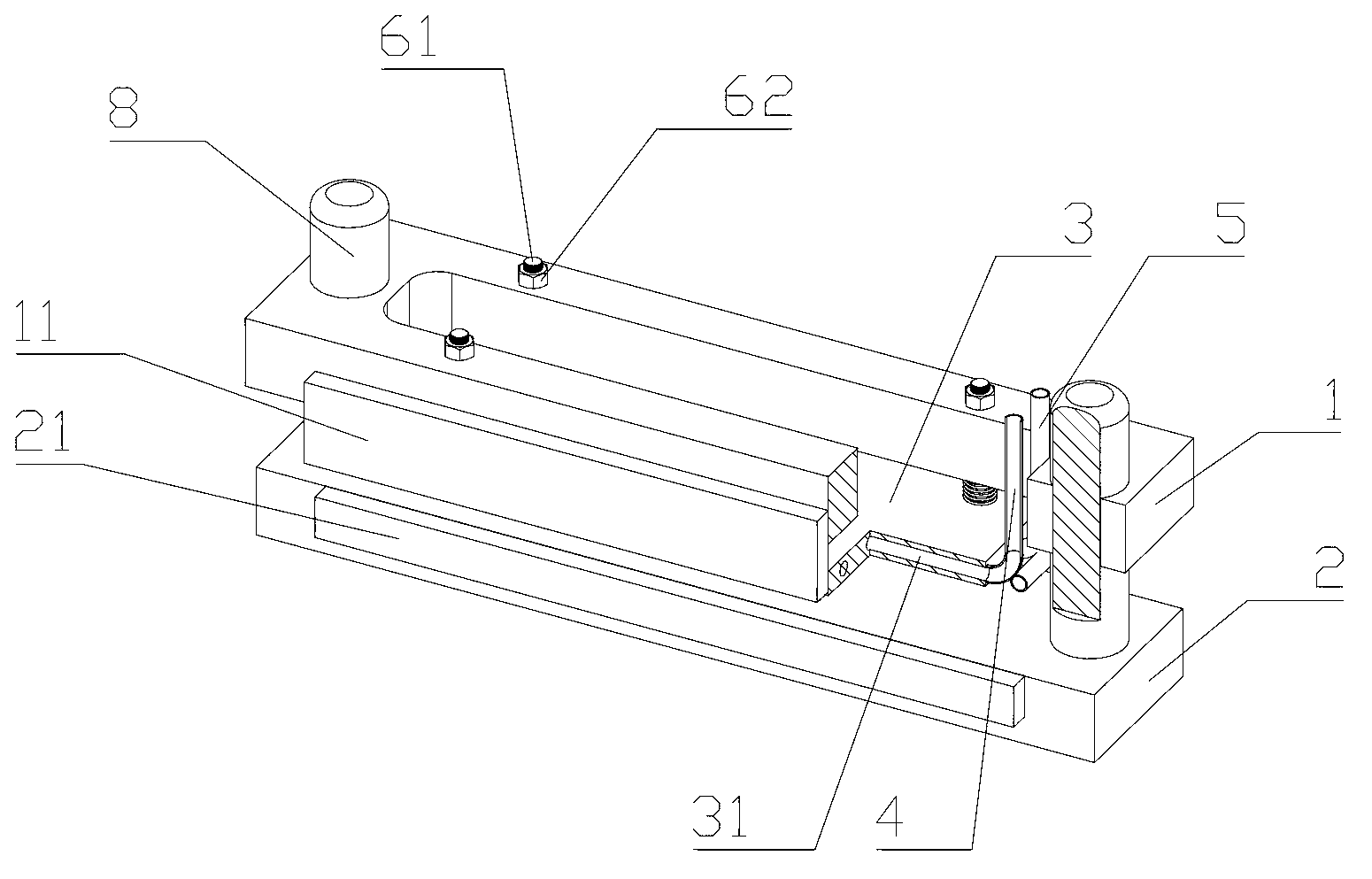

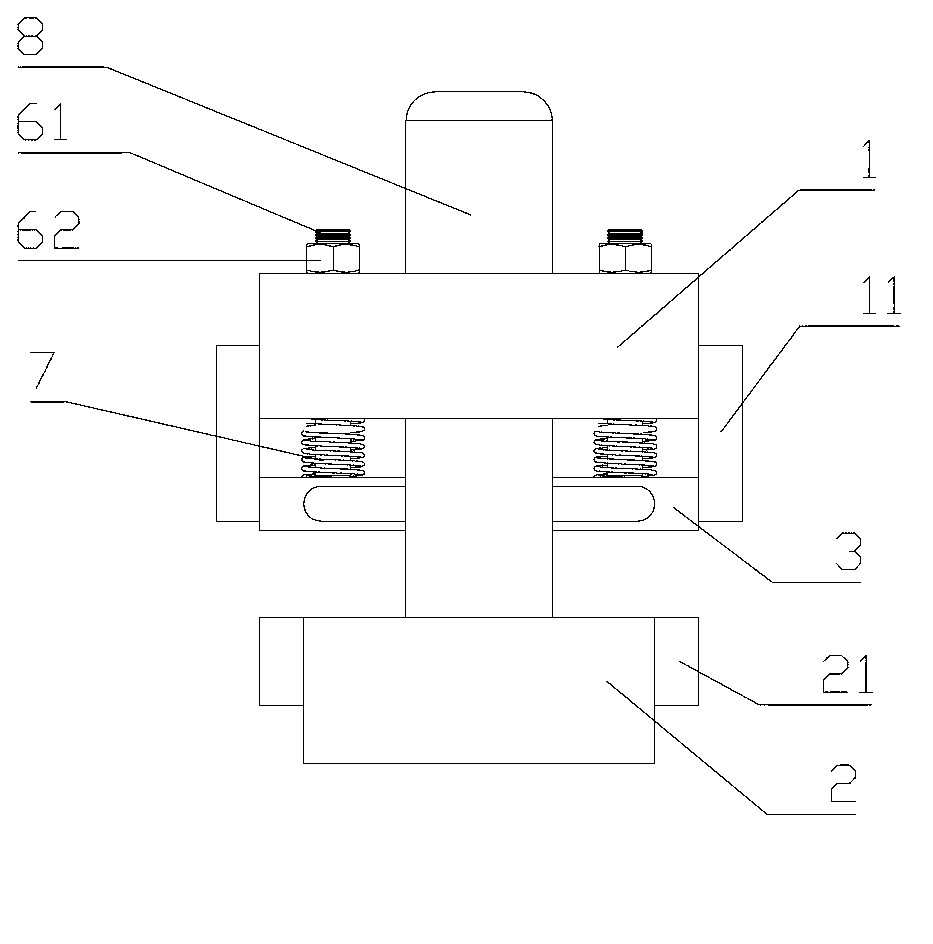

[0024] Figure 1 to image 3 As shown, a casting machine cutting knife system includes an upper knife body 1 and a lower knife body 2, the lower knife body is provided with a guide post 8, and the upper knife body is slidably connected to the guide post to realize the upper knife body. Body moves up and down relative to the lower cutter body. A pair of sides of the upper cutter body are respectively provided with an upper blade 11, and the lower cutter body is provided with a lower blade 21 matched with the upper blade, and the upper cutter body is moved up and down relative to the lower cutter body to realize the upper blade 11. The blade and the lower blade are closed or separated to achieve fixed-width cutting.

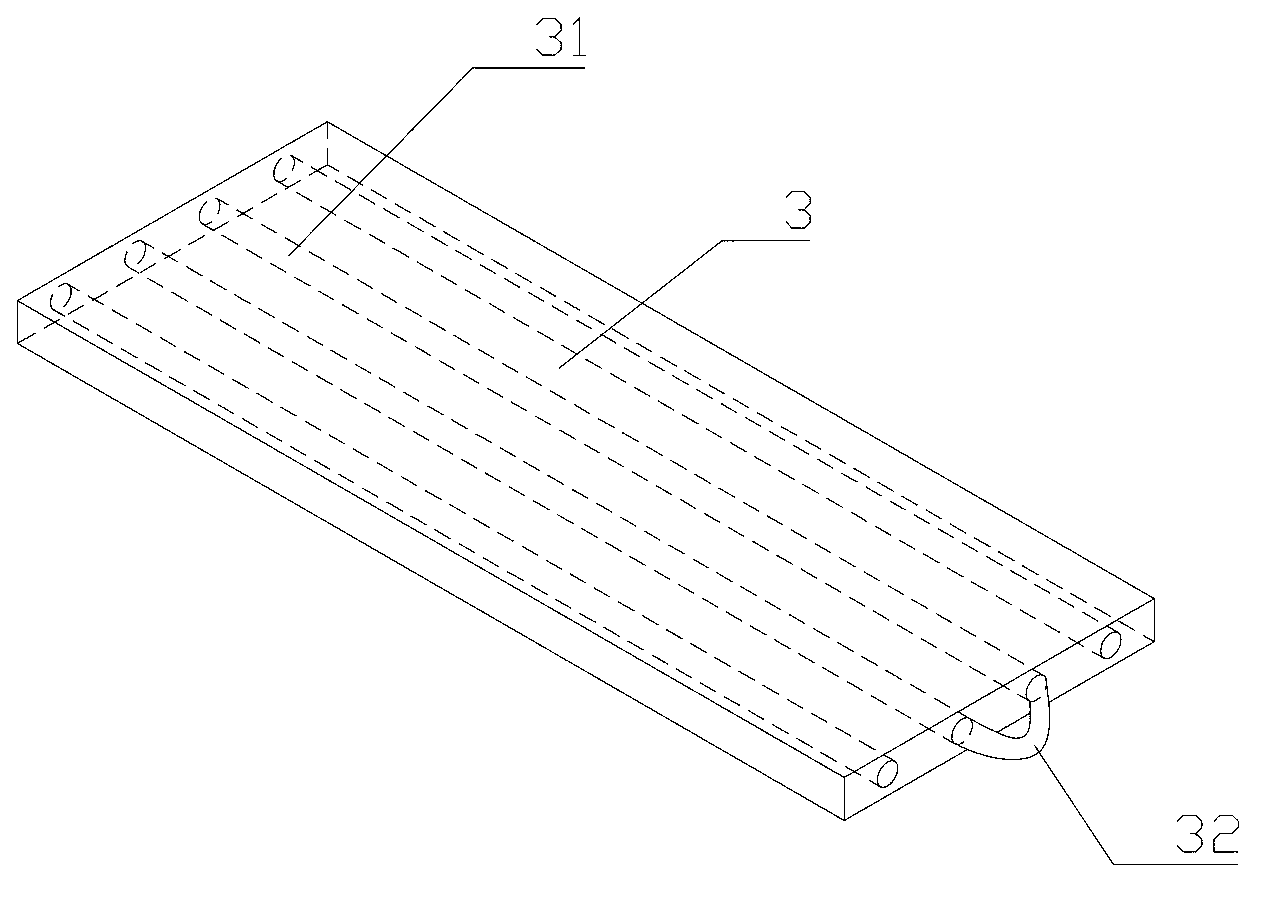

[0025] The bottom of described upper cutter body is connected with pressing plate 3, and described pressing plate is connected with upper cutter body by screw rod 61, and the lower end of described screw rod is fixed on pressing plate, and upper end passes upper cu...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the upper blade is provided with one piece, the blade is arranged on one side of the upper cutter body, and the lower blade is set in cooperation with the upper blade to realize the cutting of any width of the grid. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com