Heat pipe bending machine

A bending machine and bending mechanism technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of not being able to meet the different needs of heat pipe bending, not being able to realize digital control, and the bending accuracy is not very high , to achieve the effect of protecting the bending quality, ingenious design and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

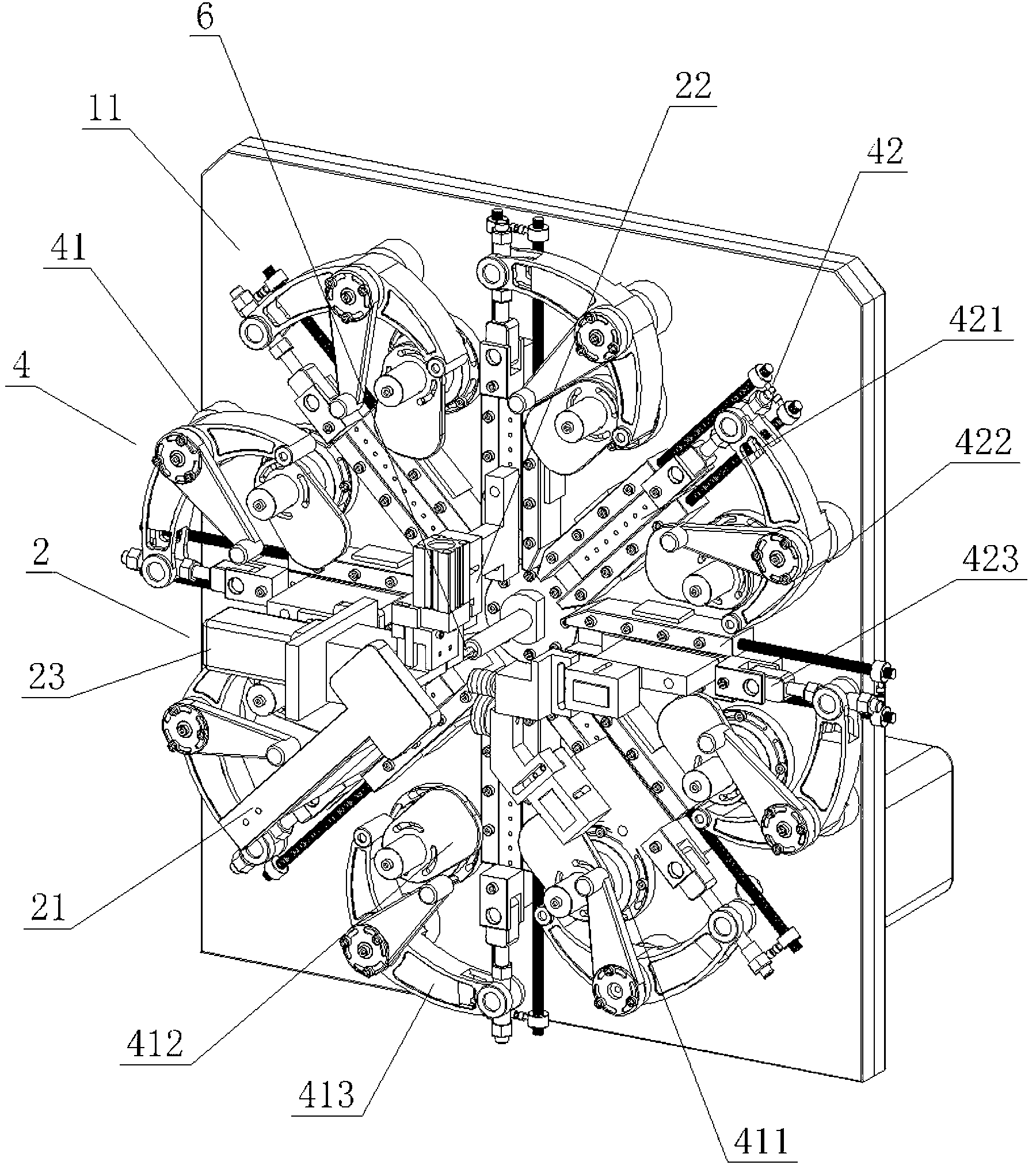

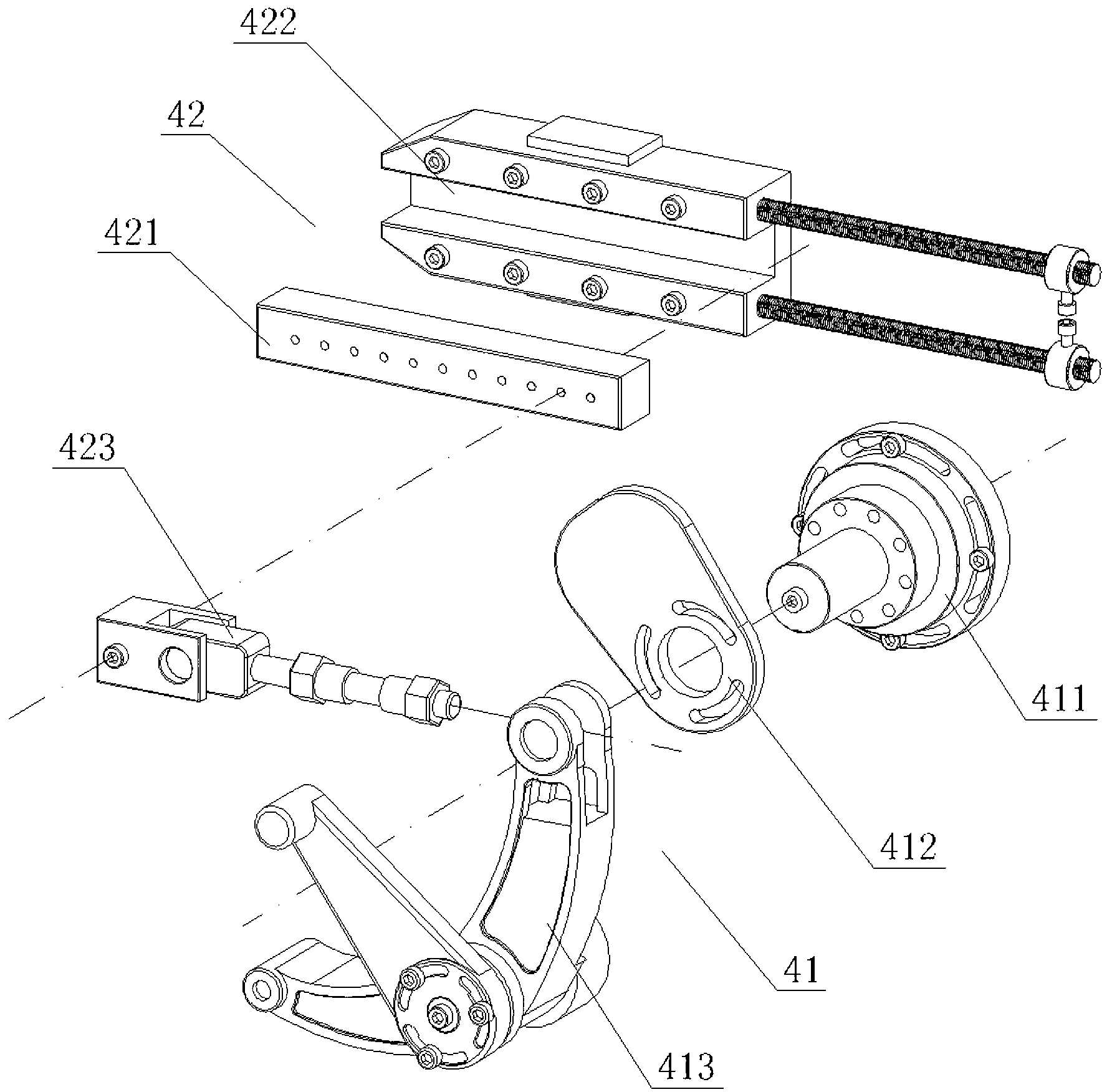

[0024] Such as Figure 1 to Figure 8 As shown, a heat pipe bending machine described in this embodiment includes a machine base 1, a feeding device 3 and a bending device 2 arranged on the machine base 1, wherein the upper part of the machine base 1 is provided with a vertical seat plate 11, The feeding device 2 is arranged behind the vertical seat plate 11, and the front of the vertical seat plate 11 is provided with a plurality of transmission connection mechanisms 4, and the bending device 2 is selectively installed on these transmission connection mechanisms 4, so the bending can be changed as required. The installation position of the bending device 2, so as to realize that the heat pipe 6 can be bent into different shapes to meet the different needs of customers, without modification, and has strong applicability. There is a motor in the base 1, and the feeding device 3 is driven by the motor. The heat pipe 6 is sent to the front end of the vertical seat plate 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com