Manufacturing method of full piece type icy hockey stick strike board

A production method and technology of hitting the plate, which are applied to rackets, flat products, sports accessories, etc., can solve problems such as poor ball control performance, and achieve the effects of good temperature resistance, not easy to rupture, and good compression creep resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

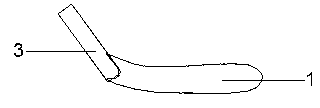

[0035] Such as Figure 4 The illustrated embodiment is a method for manufacturing a full-piece ice hockey stick strike plate, comprising the following steps:

[0036] Step 10, cutting the epoxy resin foam board into strip boards;

[0037] Step 20, placing the strip plate in a sealed bag for sealed storage;

[0038] Step 30, take out the strip plate from the sealed bag, put the strip plate into a baking oven, and bake and dehumidify at a baking temperature of 170° C. and a baking time of 3 hours;

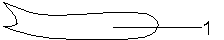

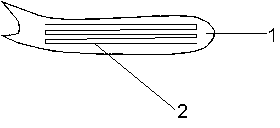

[0039] Step 40, take out the strip plate from the baking oven, and use tools to precisely cut the strip plate into the shape of a whole-piece striking plate, forming a figure 1 The one-piece striker body 1 shown;

[0040] The one-piece pad body has a length of 29 cm; a width of 7 cm; and a thickness of 7 mm.

[0041] Step 50, put the whole piece ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com