Non-welded secondary battery

A secondary battery, non-welding technology, used in battery pack parts, circuits, electrical components, etc., can solve the problems of high connection resistance, insufficient tensile strength, and slow heat transfer from the battery to reduce internal resistance and increase heat. The effect of the exported speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described.

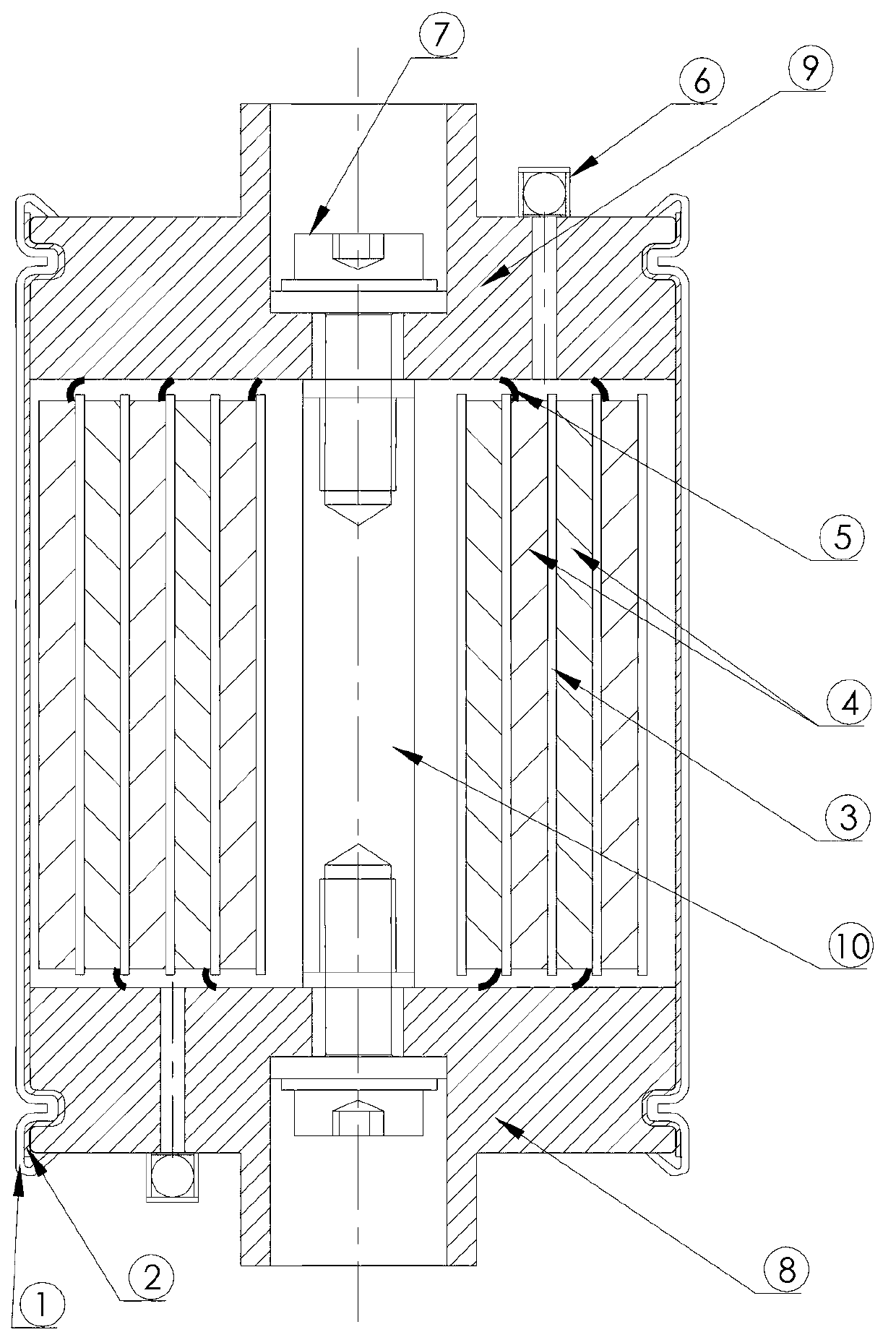

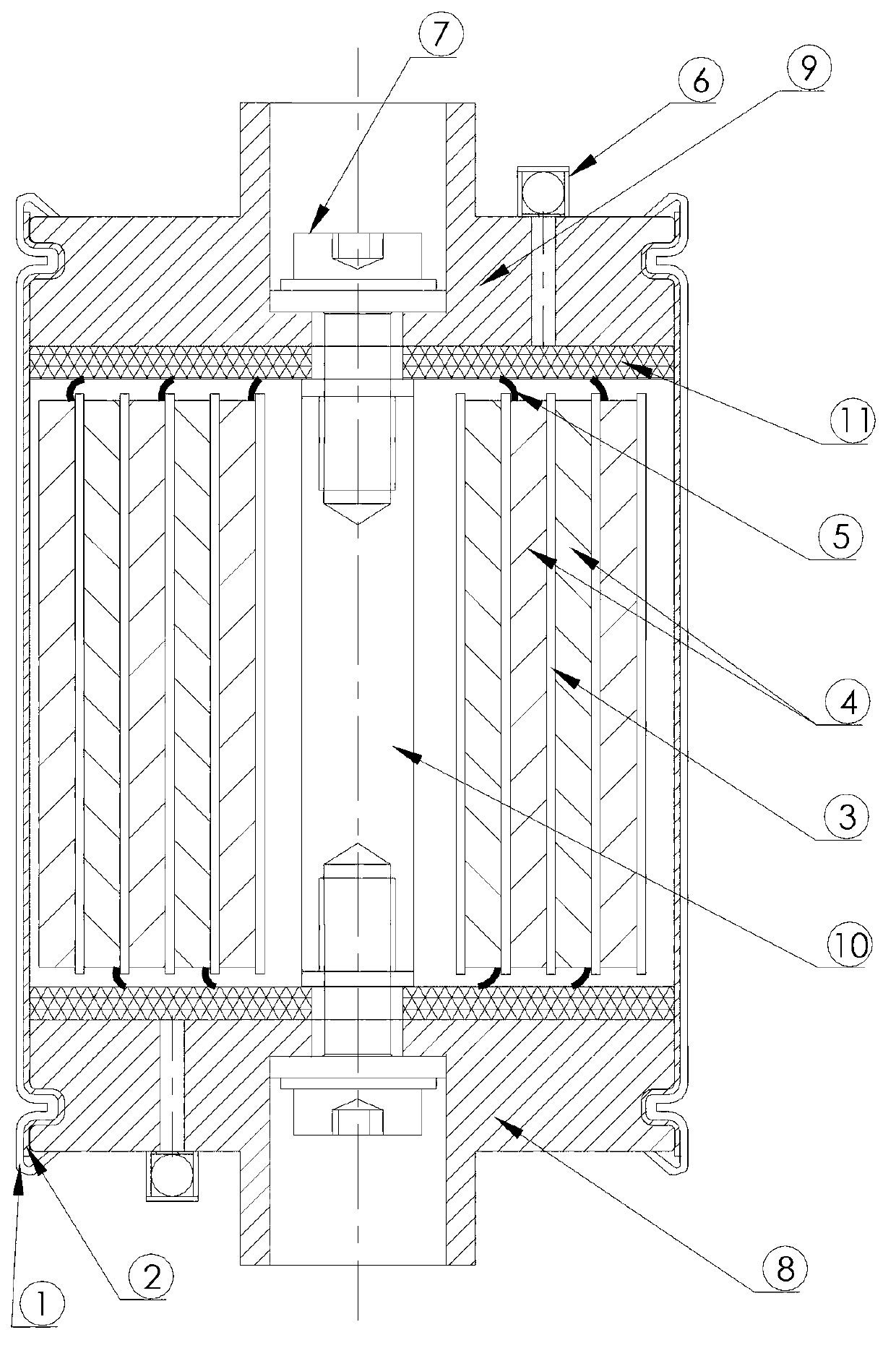

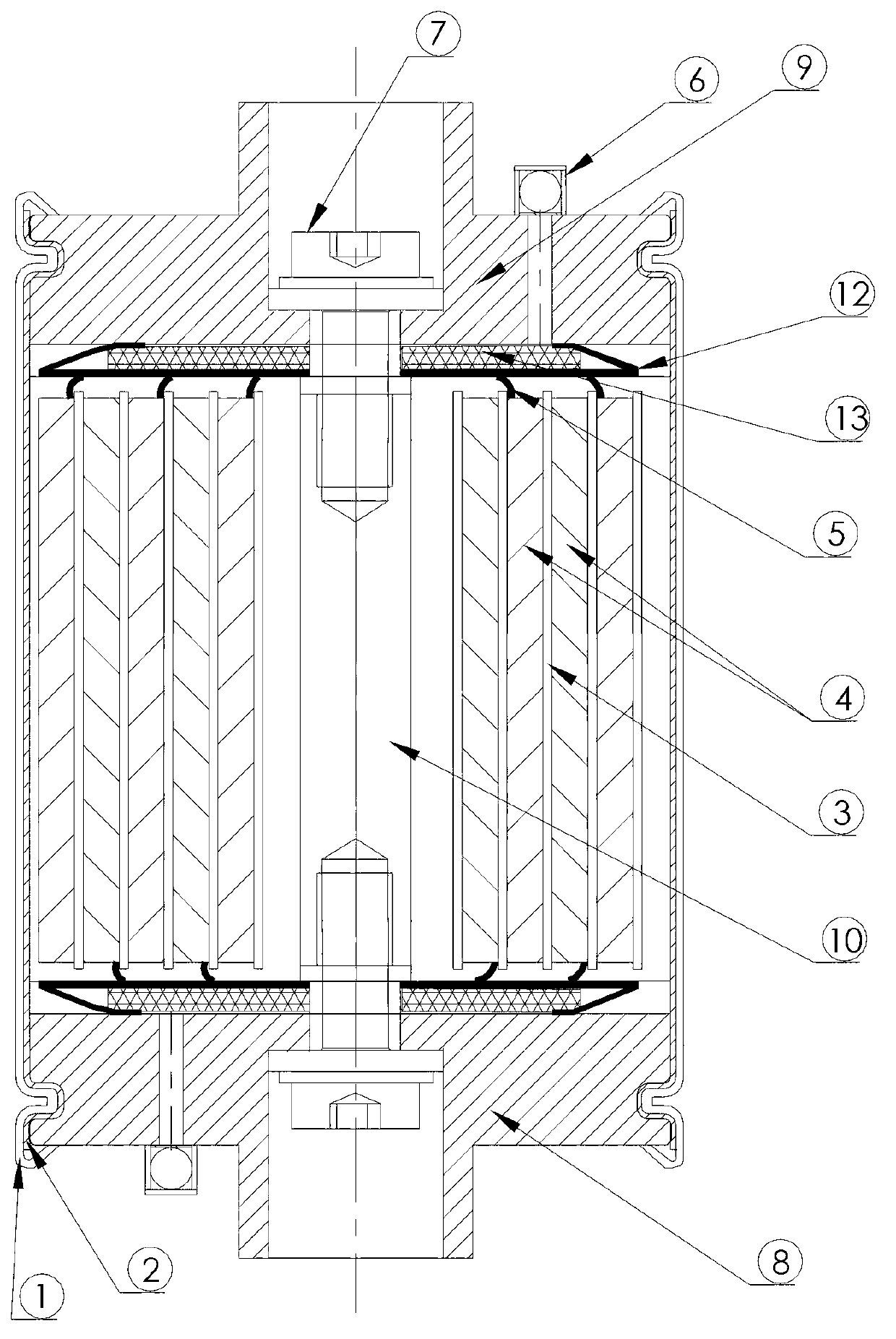

[0014] Such as figure 1 As shown, a non-welded secondary battery includes a battery case 1, a plurality of pole pieces 4 installed in the inner space of the battery case, a diaphragm 3 installed between the pole pieces 4, a number of pole pieces leading out basebands 5, two pole pieces of the battery Polarity lead-outs 8 and 9 are set at the terminals, wherein the polarity lead-out 8 is the positive lead-out, the polarity lead-out 9 is the negative lead-out, a slot hole is set on the polarity lead-outs 8 and 9, and the bolts 7 are respectively installed on the two In the end slot hole, it is connected and fixed by the fixed shaft 10 installed inside the battery. The two ends of the fixed shaft 10 are provided with screw holes that cooperate with the bolt 7; the polarity lead-out ends 8 and 9 are fixed by the bolt 7 and the fixed shaft 10. Tighten the polarity lead-out ends 8, 9, and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com