Flexible conductive thin film compositing two-dimensional graphene and one-dimensional nanowire and preparation method thereof

A flexible conductive and composite film technology, which is applied to the conductive layer on the insulating carrier, carbon silicon compound conductor, cable/conductor manufacturing, etc., can solve the problems of small size of graphene, affecting the electrical properties of graphene film, large grain boundaries, etc. , to achieve the effect of easy operation, good strength and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the flexible conductive film compounded by two-dimensional graphene and one-dimensional nanowires of the present invention comprises:

[0047] (1) graphene and nanowire are dispersed in aqueous solution or organic solvent, obtain graphene / nanowire suspension;

[0048] (2) adding a certain amount of dispersing aid to the above-mentioned suspension, and after ultrasonic dispersion, a stable graphene / nanowire mixed dispersion is obtained;

[0049] (3) Suction filter the above-mentioned mixed dispersion liquid through filter membrane or filter paper, vacuum dry, directly obtain flexible graphene / nanowire / filter membrane or filter paper composite material;

[0050] (4) Remove the filter membrane or filter paper by solvent dissolution and cold pressing to obtain an unsupported graphene / nanowire composite film, optionally, it can also be transferred to an insulating or conductive or flexible substrate;

[0051] (5) Putting the graphene / nanowire compo...

Embodiment 1

[0068] (1) Preparation of reduced graphene oxide

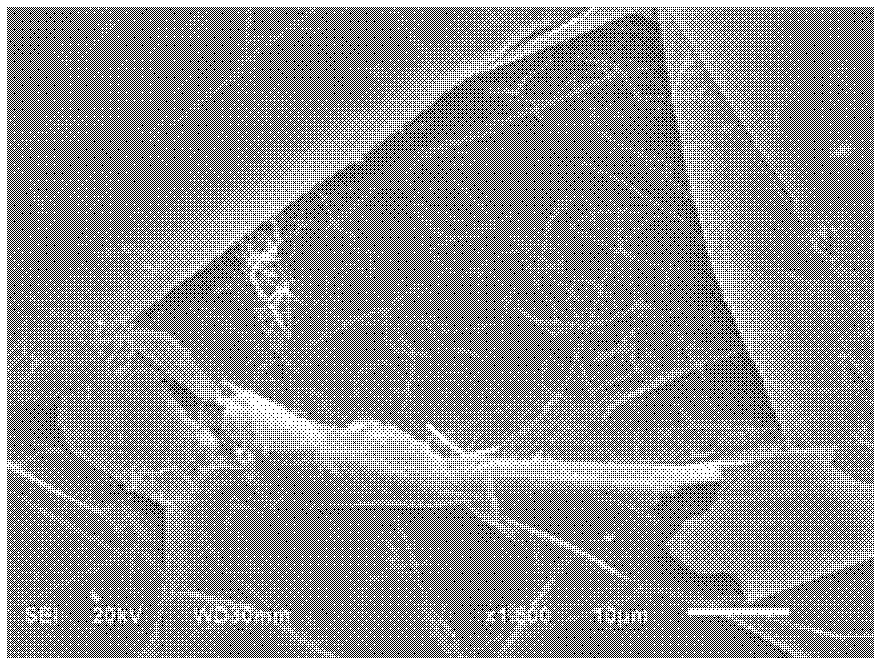

[0069] Reduced graphene oxide was prepared by the typical Hummer method, put in a large beaker in an ice-water bath, and add 110 mL of concentrated H 2 SO 4 , stirred on a magnetic stirrer, added 5g of 100 mesh flake graphite, and then added 2.5g NaNO 3 , then slowly add 15g KMnO 4 , stirred and reacted on a magnetic stirrer for 90 minutes, slowly added 220mL deionized water, heated to keep the temperature at about 70-100°C, slowly added a certain amount of hydrogen peroxide (5%) for high temperature reaction, and the reacted solution was centrifuged several times in a centrifuge Wash to obtain graphene oxide, mix 0.1 g of the prepared graphite oxide with 100 mL of deionized water, and ultrasonically vibrate in an ultrasonic oscillator for 30 minutes. Then, add 1g NaBH 4 , heated and refluxed at 100° C. for 8 hours, left to stand and filtered, and dried naturally to collect graphene, and the number of graphene layers is 1-...

Embodiment 2

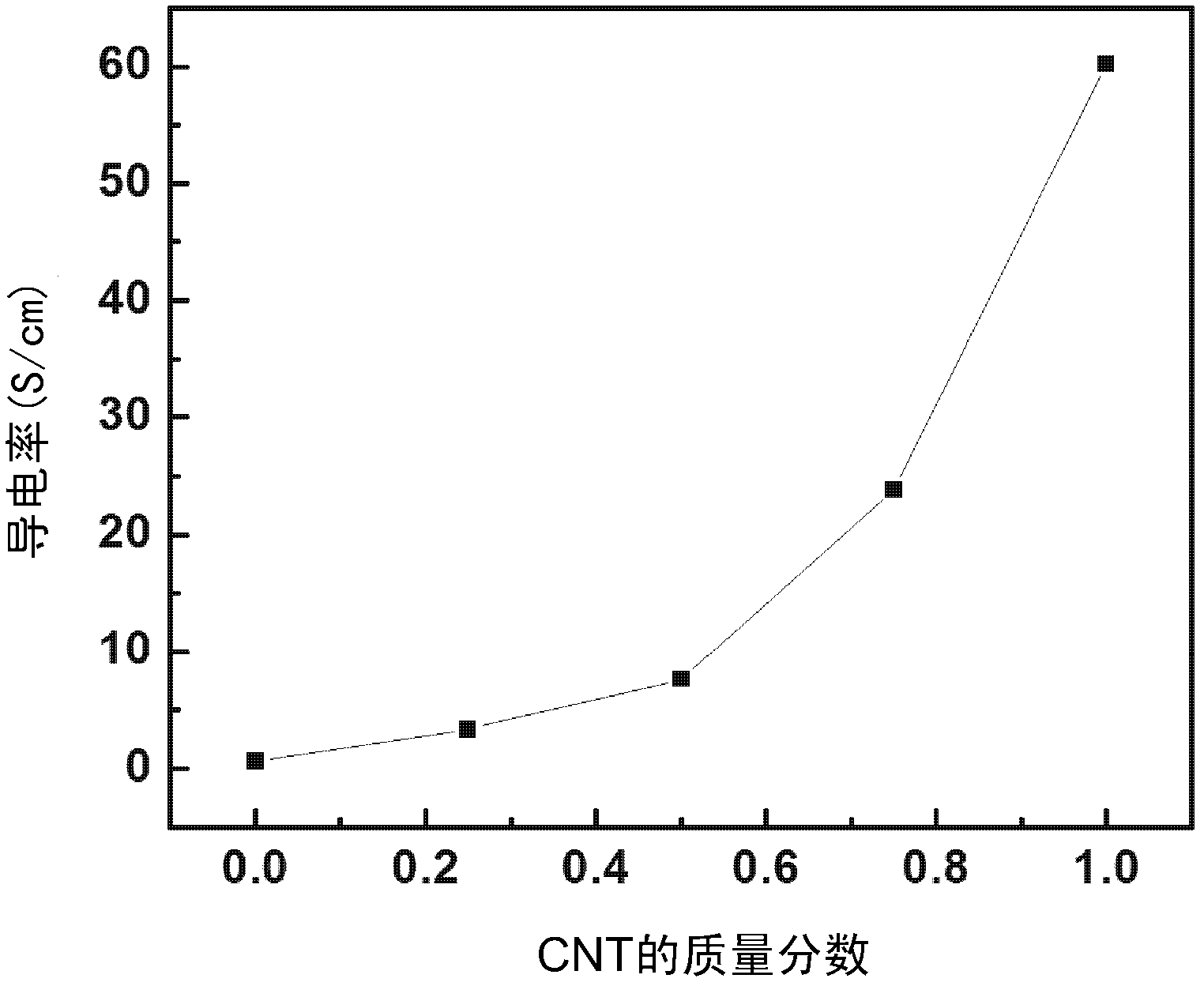

[0075] The preparation method is basically the same as in Example 1, except that in step (2), 7.5 mg of carbon nanotubes and 22.5 mg of redox graphene are used to composite, and the sheet resistance of the graphene / carbon nanotube composite film is 155 Ω / sq ., the conductivity is 3.36S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com