Torsional mode magnetostrictive sensor used for minor-diameter metal bar

A torsional mode and magnetostrictive technology, which is applied in the direction of instruments, scientific instruments, ultrasonic/sonic waves/infrasonic waves, etc., can solve the problems of exciting torsional mode ultrasonic guided waves, etc., and achieve the effect of easy disassembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

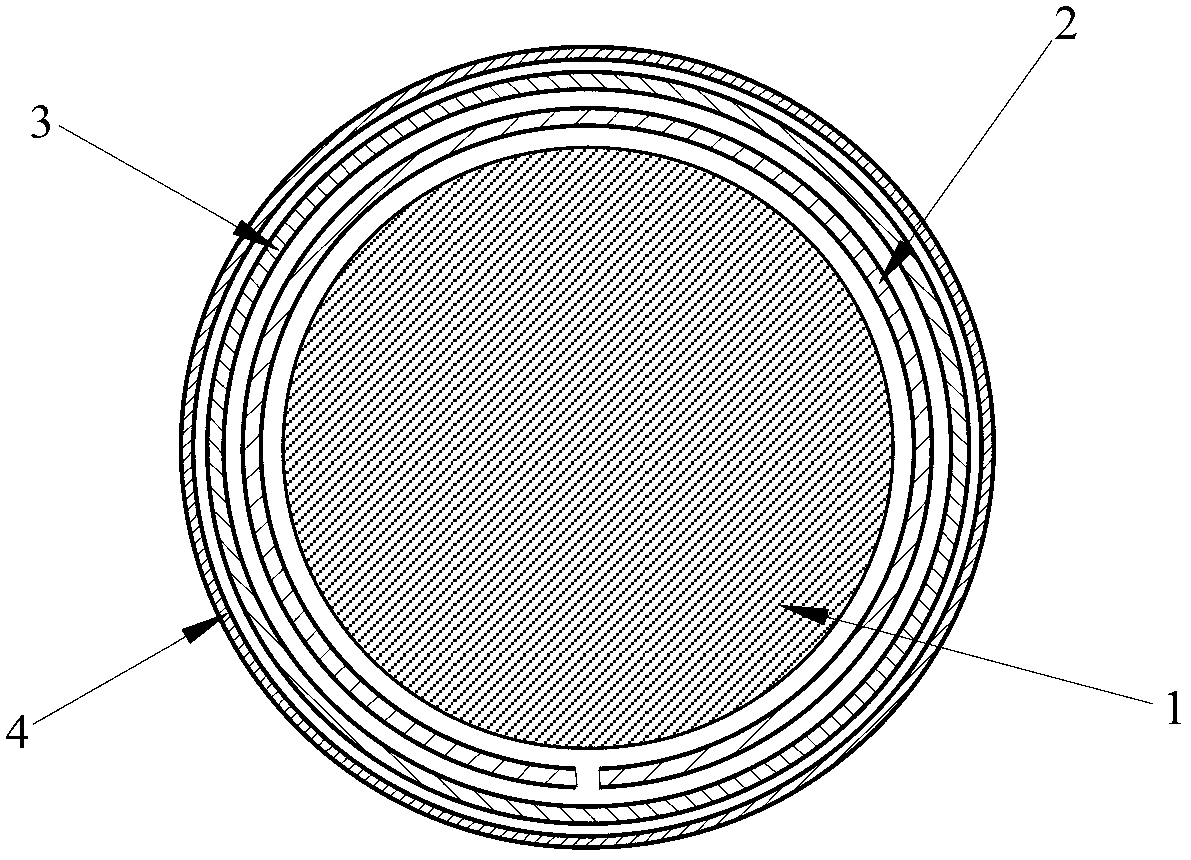

[0012] like figure 1 As shown, the internal structure of the torsional modal magnetostrictive sensor for small-diameter metal rods is composed of three parts: iron-cobalt alloy patch 2, support sleeve 3 and induction coil 4. Epoxy glue is filled between the iron-cobalt alloy patch 2 magnetized by the bias magnetic field and the surface of the small-diameter metal rod 1 for pasting. The induction coil 4 is wound on the support sleeve 3 ; the small diameter metal rod 1 is inserted into the support sleeve 3 and maintains a clearance fit relationship with the support sleeve 3 .

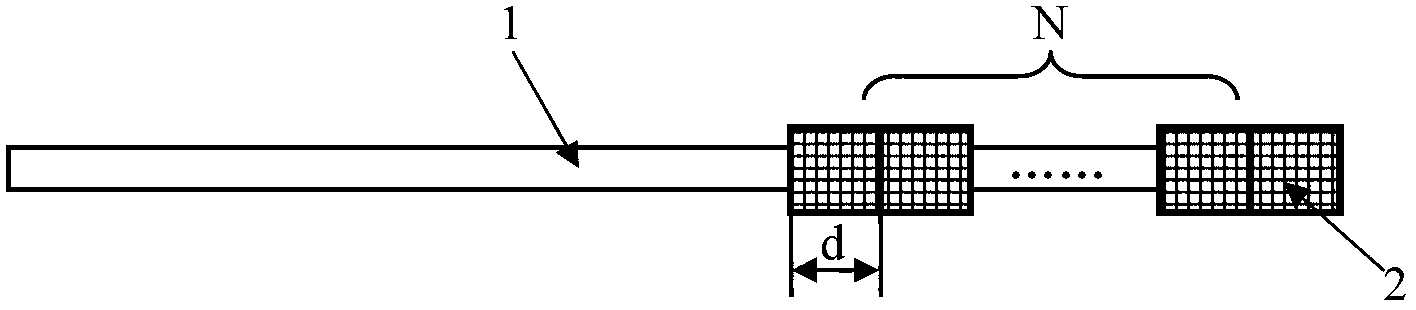

[0013] figure 2 Shown is a schematic diagram of the arrangement of the iron-cobalt alloy patch 2 on the small-diameter metal rod 1 with a diameter of D. Before the iron-cobalt alloy patch 2 is pasted on the surface of the small-diameter metal rod 1, it needs to be pre-bent. A flexible annular structure is formed. The length L of the single-segment iron-cobalt alloy patch 2 is equal to the perimeter L=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com