Vacuum gas collection system for core gas of natural gas hydrate drilling field

A hydrate and natural gas technology, applied in sampling devices and other directions, can solve the problems of gas components being easily affected by air or ambient temperature, insufficient gas intake, etc., to eliminate the influence of ambient temperature changes, accelerate the release rate, and speed up the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is a detailed description of the gas hydrate drilling site core gas vacuum gas extraction system of the present invention in conjunction with the accompanying drawings, but this does not limit the protection scope of the present application.

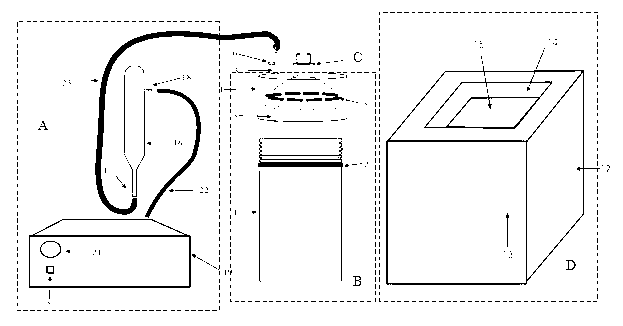

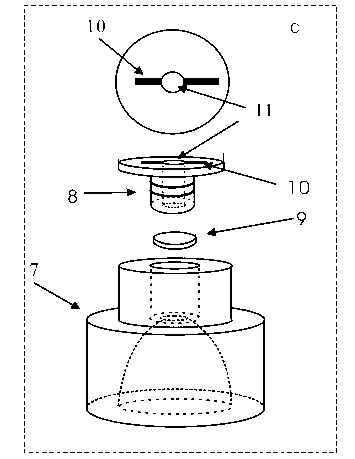

[0035] as attached figure 1 As shown, the overall components of the vacuum gas extraction system for core gas at the natural gas hydrate drilling site of the present invention include: a vacuum unit A, a gas collection tank B, a gas extraction unit C, and a degassing environmental chamber D.

[0036] Wherein the vacuumizing unit A comprises making vacuum glass tube 16, vacuum pump 19, connecting flexible pipe 22-23 and plastic water tank 24, and making vacuum glass tube 16 comprises a through pipe and a side through pipe, and the through pipe connects flexible pipe 23 and through rubber The auxiliary hole pipe 5 on the tank cover 4 in the gas collecting tank B is connected, and a straight pipe valve 17 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com