Movable container type high-precision micro-pressure detection device

A detection device, high-precision technology, applied in the direction of measuring device, pressure difference measurement between multiple valves, instruments, etc., can solve the problems of high cost and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, further illustrate the present invention.

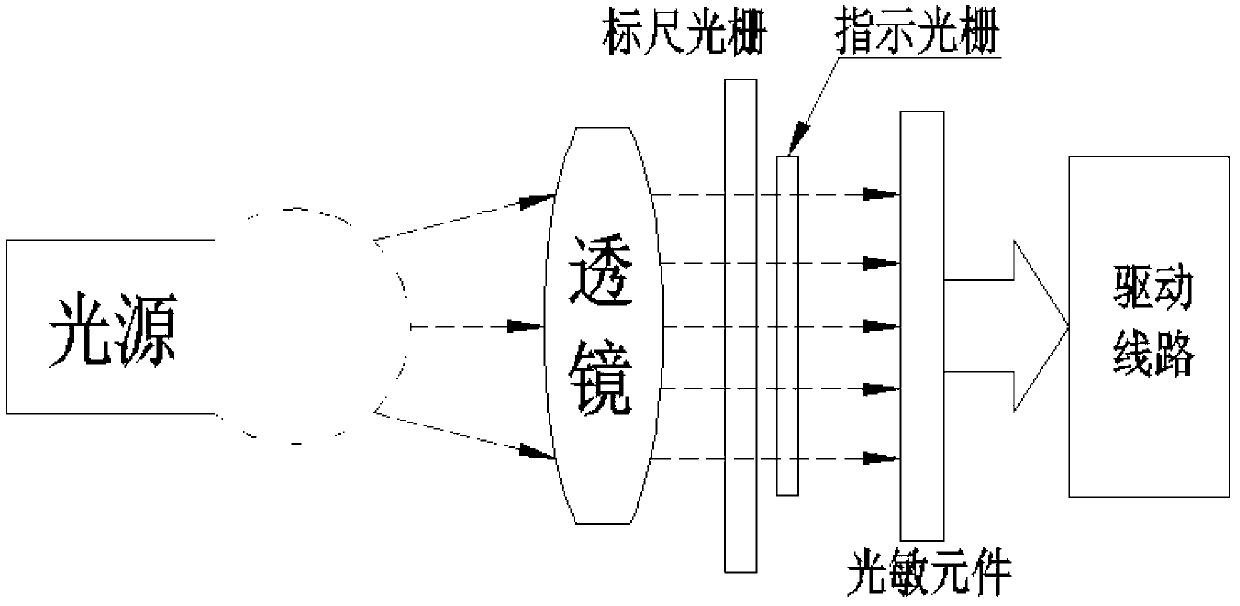

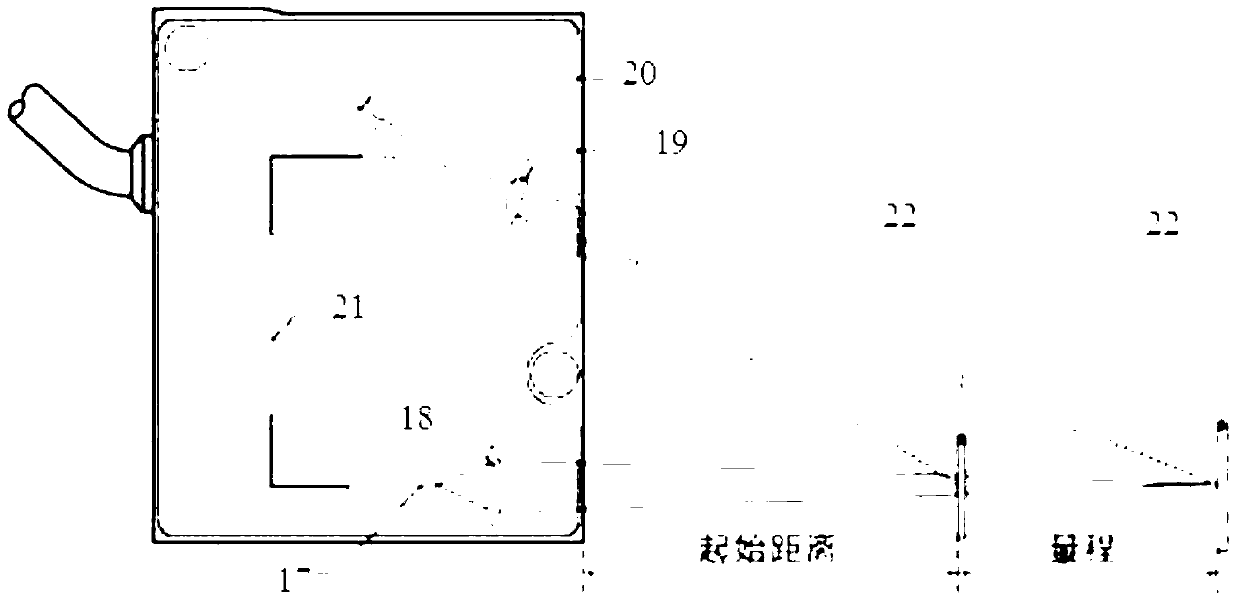

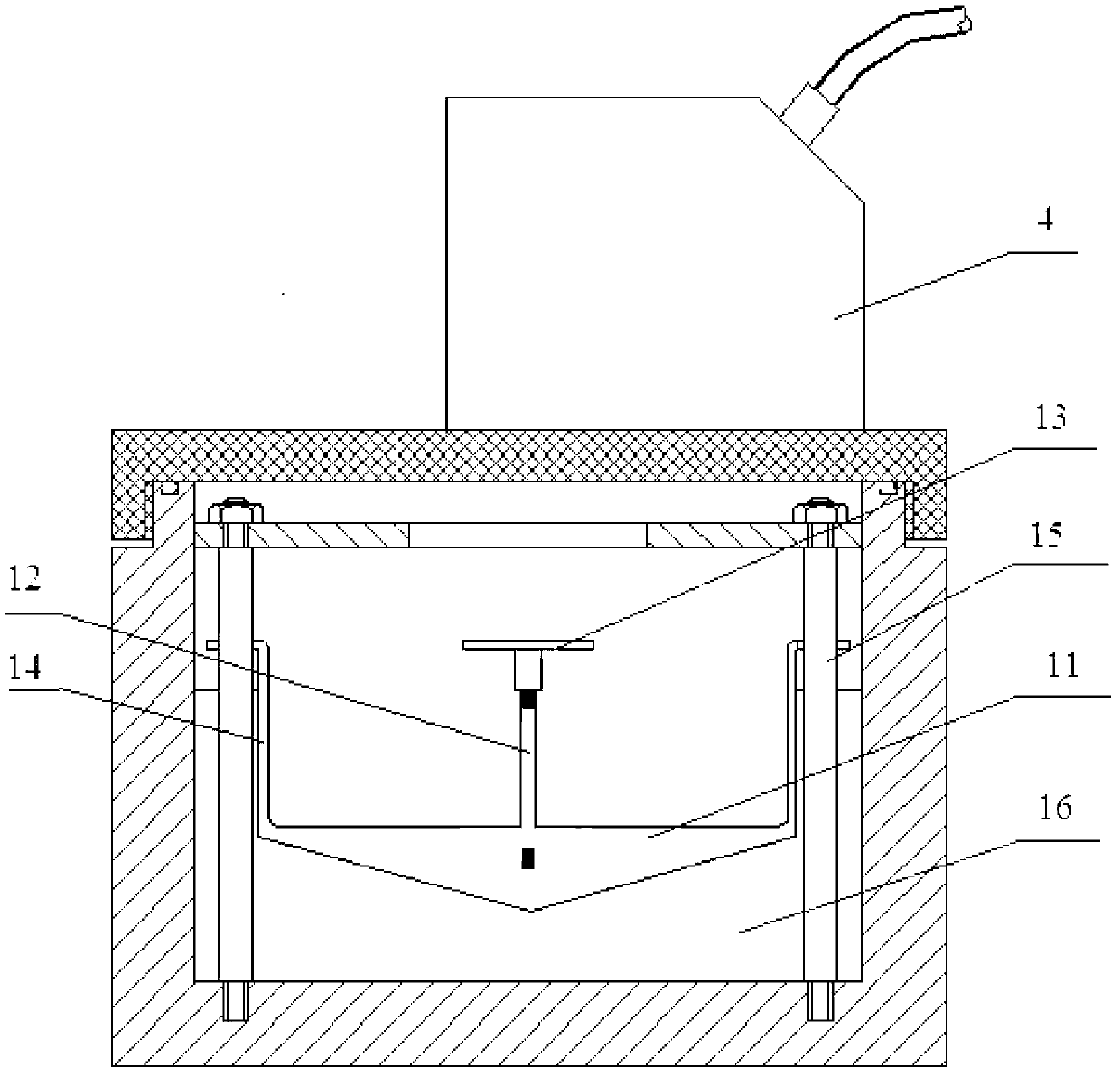

[0031] In view of the shortcomings of the above analysis, the present invention designs a micro-pressure measuring device with a measurement range of ±8kPa and a measurement accuracy of ±0.1Pa. This set of micro-pressure measurement device adopts Moiré fringe subdivision grating ruler, and the measurement accuracy reaches ±2μ, which is used for the measurement of the displacement of the movable container. Use two laser displacement meters to measure the liquid level in movable and fixed containers, so that you don't need to use human eyes to observe the position of the cone tip and take a reading directly. Temperature sensors are placed in each container and pipeline for temperature monitoring and real-time correction. The movement of the movable container is driven by the stepping motor and the lifting screw to move the container up and down, which avoids the trouble of turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com