Stand pole and floating bridge adjusting structure, and floating dock applying stand pole and floating bridge adjusting structure

A technology for adjusting structures and floating docks, applied in the field of floating docks, can solve problems such as easy wear and tear of the coating, reduce the service life of floating docks, etc., and achieve the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

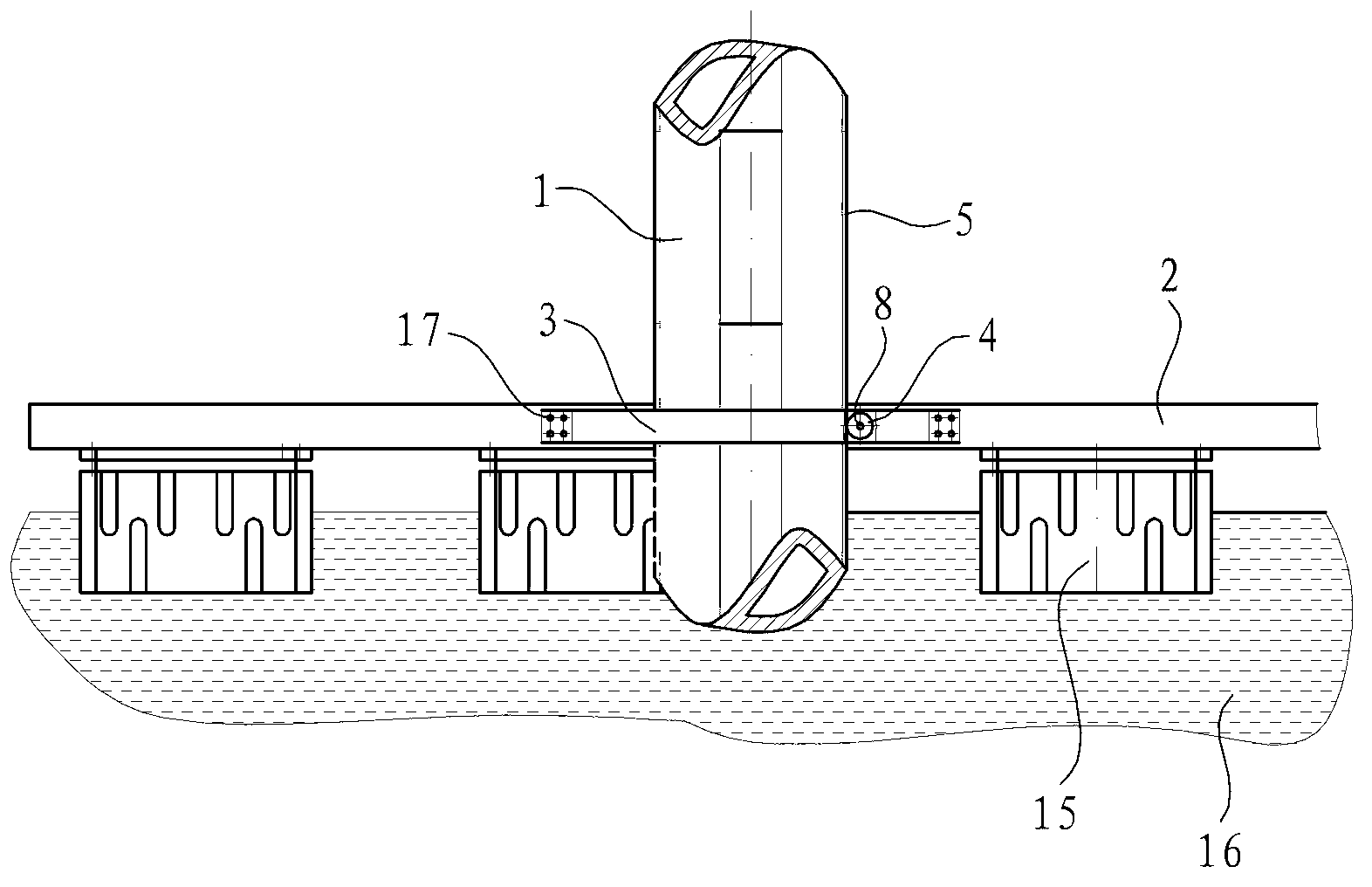

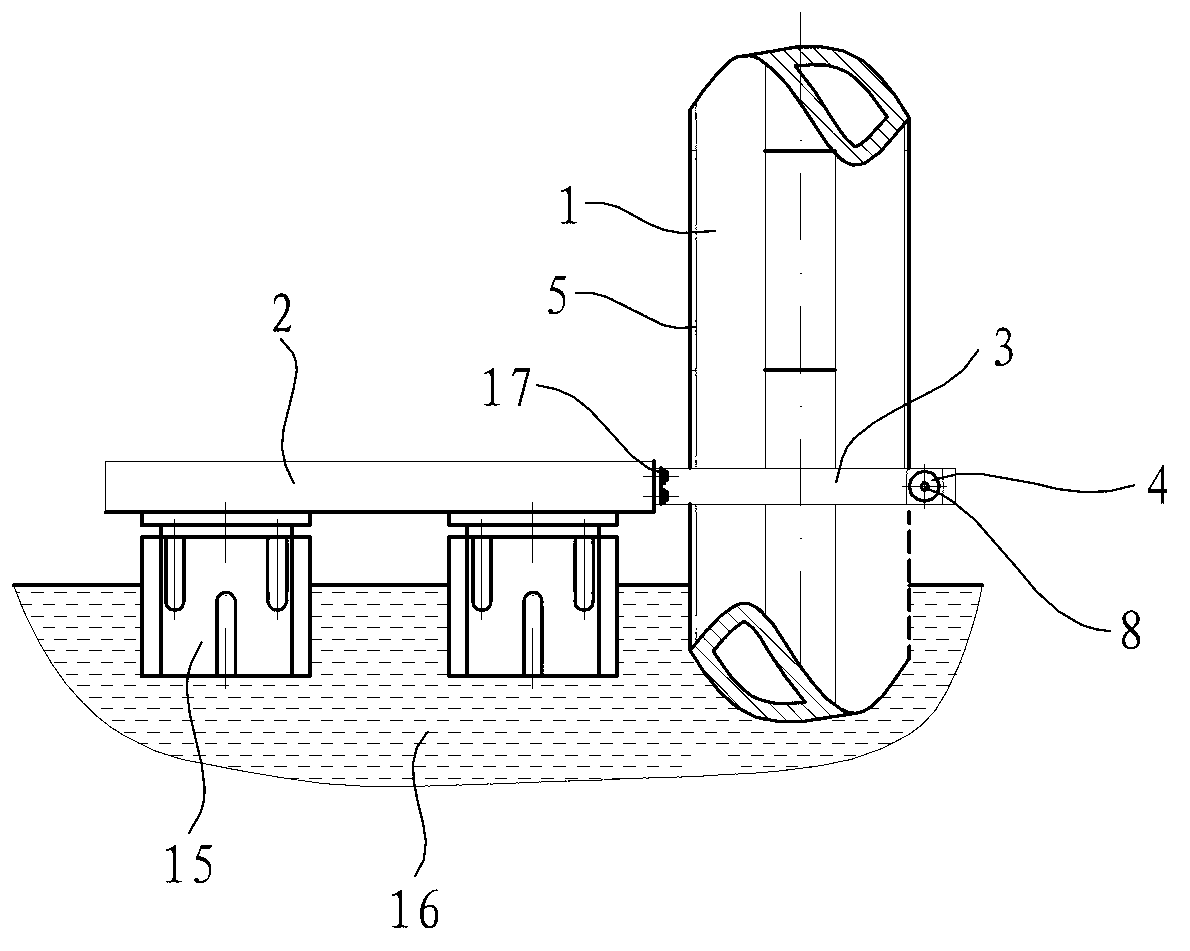

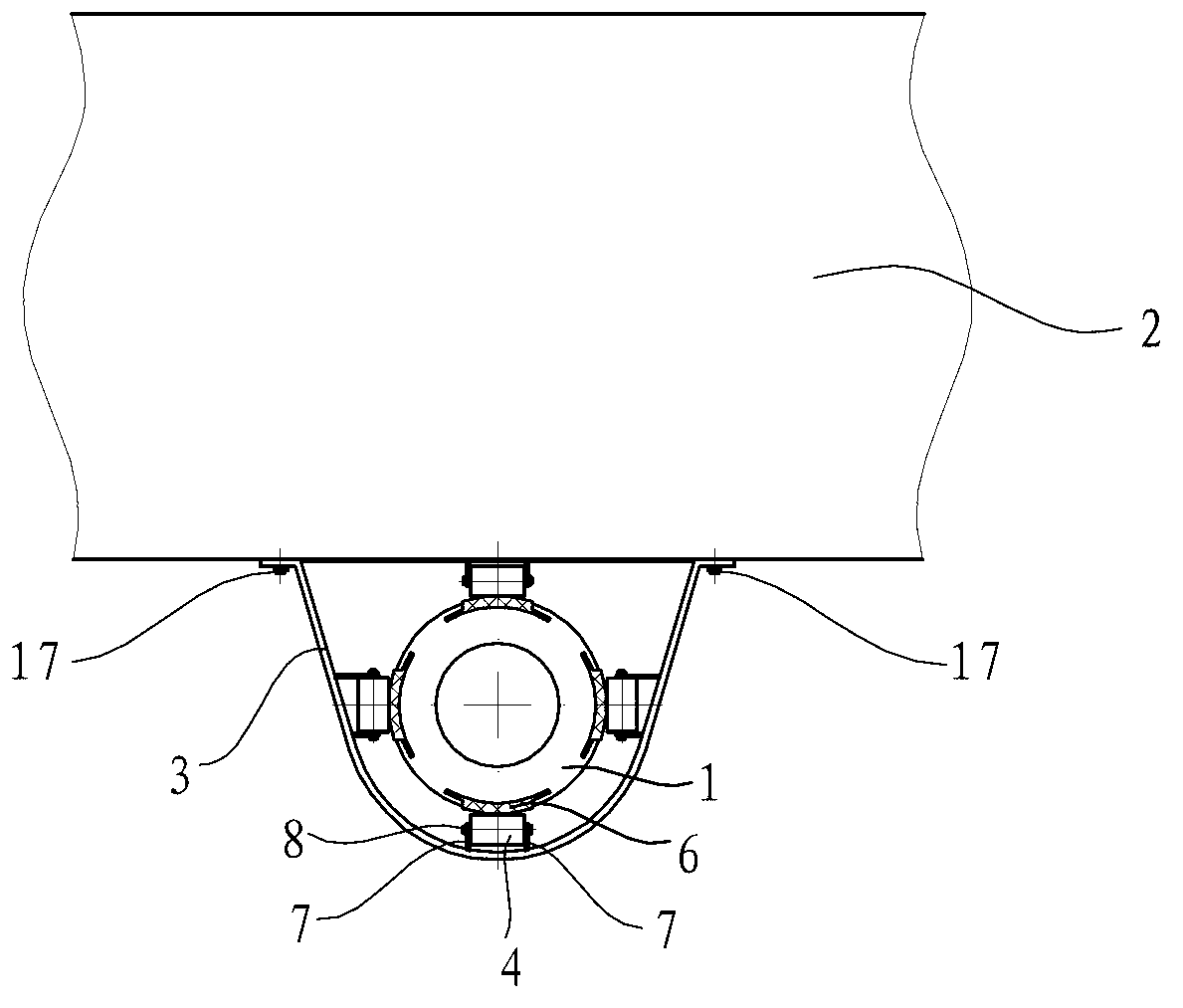

[0049] Embodiment one: if Figure 10 to Figure 14 As shown, the floating wharf in this embodiment includes components such as upright piles 1, auxiliary upright piles 10, pontoon bridge 2 and connecting channel 9, wherein the upright piles 1 and auxiliary upright piles 10 are all arranged on the seabed and exposed to the sea surface, and the pontoon bridge 2 is an integral skeleton formed by connecting multiple unit frames in series or in parallel, each unit frame adopts angle steel or I-beam as a welded component, and the floating bridge 2 and the vertical pile 1 are provided with the adjustment given in the above embodiment structure. A bridge deck is installed above the pontoon 2 to form a pontoon bridge deck, and a pontoon 15 is installed below the pontoon 2 , and the yacht 18 is parked on the mooring sea surface near the pontoon 2 . In order to prevent the wharf from being eroded by seawater and sea breeze, the surface of the unit frame is brushed with a coating resistan...

Embodiment 2

[0051] Embodiment two: if Figure 15 to Figure 20 As shown, the difference between the floating pier in this embodiment and the floating pier in Embodiment 1 lies in the connection channel. In this embodiment, the connecting channel 9 includes a fixed section 91 and a movable section 92, wherein the fixed section 91 is erected between the coast 11 and the auxiliary pile 10, the upper end of the movable section 92 is hinged with the fixed section 91, and the movable section 92 The lower end is slidingly connected on the floating bridge 2 . Specifically, the movable section 92 specifically includes components such as an upper beam frame 92a, a lower beam frame 92b, a step pedal 92c, a first pulley 92d, and a second pulley 92e. There are two upper beam frames 92a, which are parallel to each other and obliquely arranged on both sides of the connecting passage 9, and the top of the upper beam frame 92a is hinged with the fixed section 91 erected at the end of the auxiliary pile 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com