Skin-core structure light-reflecting composite fiber and preparation method thereof

A composite fiber and skin-core structure technology, which is applied in fiber processing, conjugated synthetic polymer artificial filament, textiles and papermaking, etc., can solve the problems of short service life, easily damaged surface structure, and attenuation of reflective efficiency, and achieve production The environment is clean and safe, the production cost is reduced, and the effect of avoiding instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing reflective composite fibers, using a composite spinning process, the spinneret assembly is a sheath-core composite spinning assembly, and polyimide (polyester or polyamide materials with a refractive index greater than 1.5, please specify the substance) as The skin layer material, air (polyester or polyolefin material or air with a refractive index less than 1.5, please specify the material) as the core layer material, is respectively melted and extruded, metered, and then enters the same skin-core spinneret assembly, two melts Converge at the spinneret hole in the assembly and extrude the spinneret hole. The fiber is wound after cooling and oiling. The spinning temperature is 230-300°C and the winding speed is 500-3200m / min. Stretching to obtain finished silk.

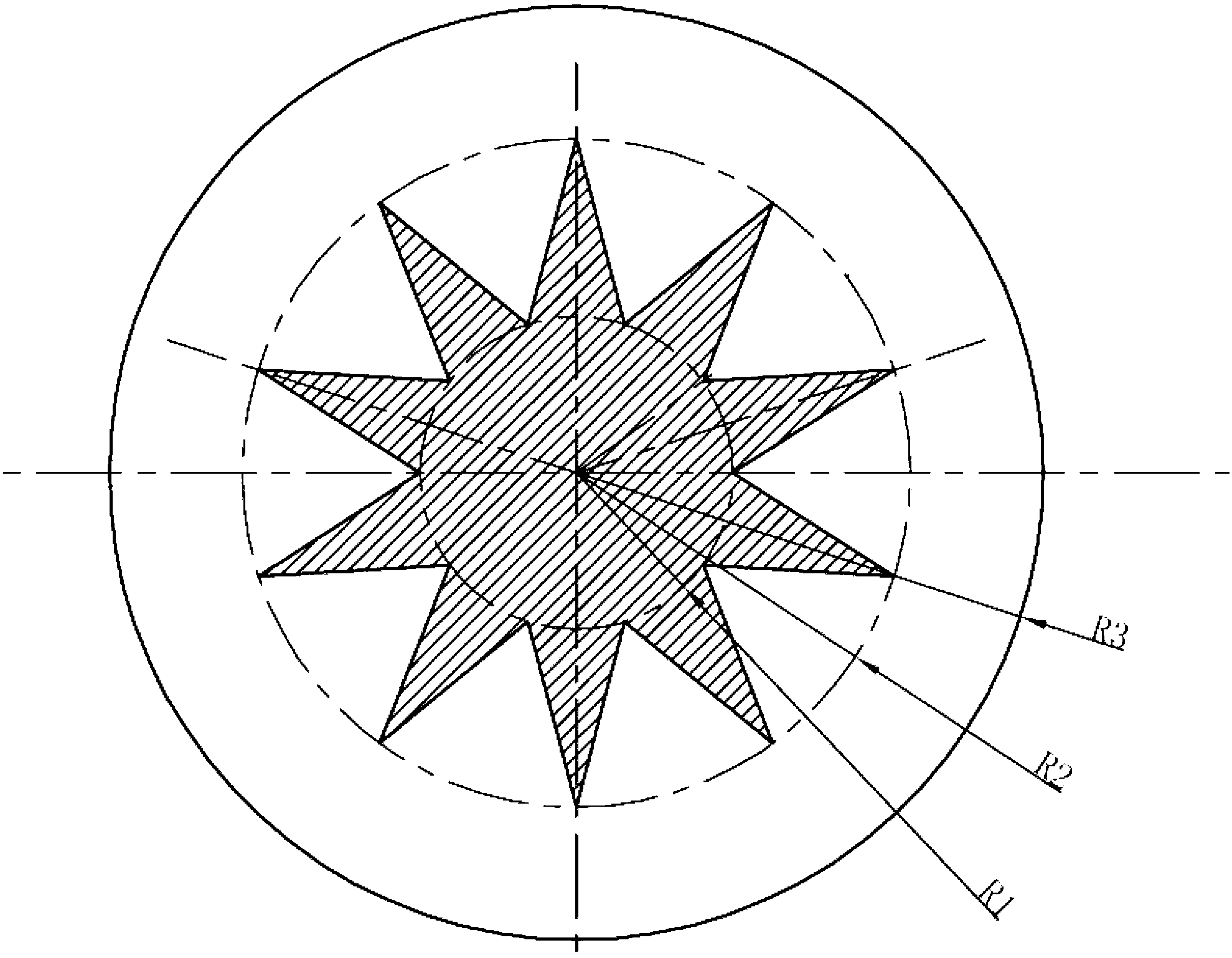

[0033] The spinneret assembly is a sheath-core composite spinneret with a double-layer hole structure, wherein the cross-section of the center hole of the upper distribution plate is a re...

Embodiment 2

[0035] A preparation method of reflective composite fiber, which adopts the composite spinning process, the spinneret assembly is a sheath-core type composite spinning assembly, and polycarbonate (polyester or polyamide material with a refractive index greater than 1.5, please specify the substance) as the skin layer Material, (polyester or polyolefin material or air with a refractive index less than 1.5, please specify the substance) polyvinylidene fluoride is used as the core material, which is melted and extruded and metered, and then enters the same sheath-core spinneret assembly, two kinds The melts meet at the spinneret holes in the assembly and are extruded from the spinneret holes. The fibers are cooled and oiled and then wound. The spinning temperature is 230-300°C and the winding speed is 500-3200m / min. The finished silk is obtained by stretching the silk.

[0036] The spinneret assembly is a sheath-core composite spinneret with double-layer hole structure, wherein t...

Embodiment 3

[0038] A method for preparing reflective composite fibers, using a composite spinning process, the spinneret assembly is a sheath-core composite spinning assembly, polyvinylcarbazole (polyester or polyamide materials with a refractive index greater than 1.5, please specify the substance) As the skin layer material, (polyester or polyolefin material with a refractive index less than 1.5 or air, please specify the substance) polybutylacrylate as the core layer material is melted and extruded and metered, and then enters the same skin-core spinneret assembly, The two melts meet at the spinneret holes in the assembly and are extruded out of the spinneret holes. The fibers are cooled and oiled and then wound. The spinning temperature is 230-300°C and the winding speed is 500-3200m / min. The wound yarn is stretched to obtain the finished yarn.

[0039] The spinneret assembly is a sheath-core composite spinneret with double-layer hole structure, wherein the cross-section of the center...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com