Clamp for reversely fixing a plurality of substrates of magnetic-control sputtering equipment and clamping method thereof

A magnetron sputtering and substrate technology, applied in the direction of sputtering plating, ion implantation plating, metal material coating process, etc., to achieve the effect of preventing blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in combination with specific embodiments.

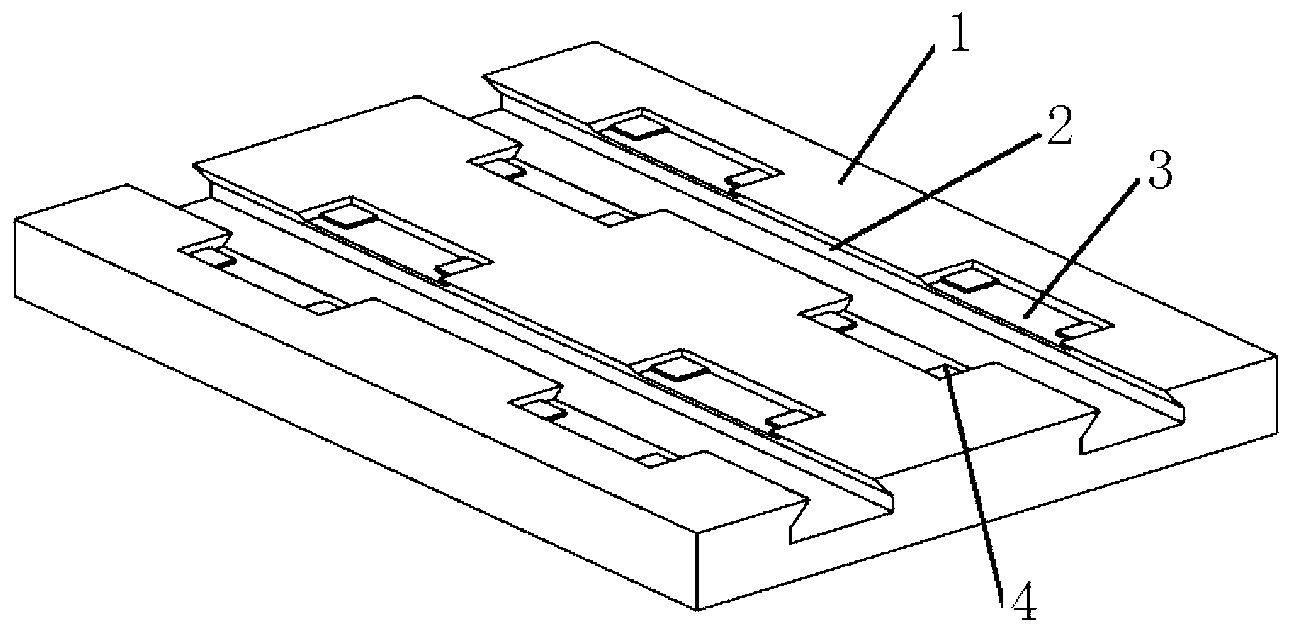

[0019] The present invention is a fixture used for fixing multiple substrates upside down for magnetron sputtering equipment, including a base 1 and a fixing piece.

[0020] Such as figure 1 As shown, the base 1 is provided with several dovetail grooves 2, and the top surface of the dovetail groove 2 is provided with a plurality of rectangular grooves 3 for placing the substrate 5 at intervals, and the size of the rectangular grooves 3 is uniform. The area of the substrate 5 is basically the same, the four corners of the rectangular groove 3 are respectively fixed with gaskets 4, and the effect of the gasket 4 is that when the substrate 5 is put into the rectangular groove 3, the thickness of the substrate 5 can be reduced. The contact area with the bottom surface of the rectangular groove 3, thereby reducing the wear rate of the substrate 5, such as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com