Fully automatic bottle conveying line

An assembly line, fully automatic technology, applied in bottle filling, liquid bottling, packaging, etc., can solve problems such as high cost and complex structure of industrial robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

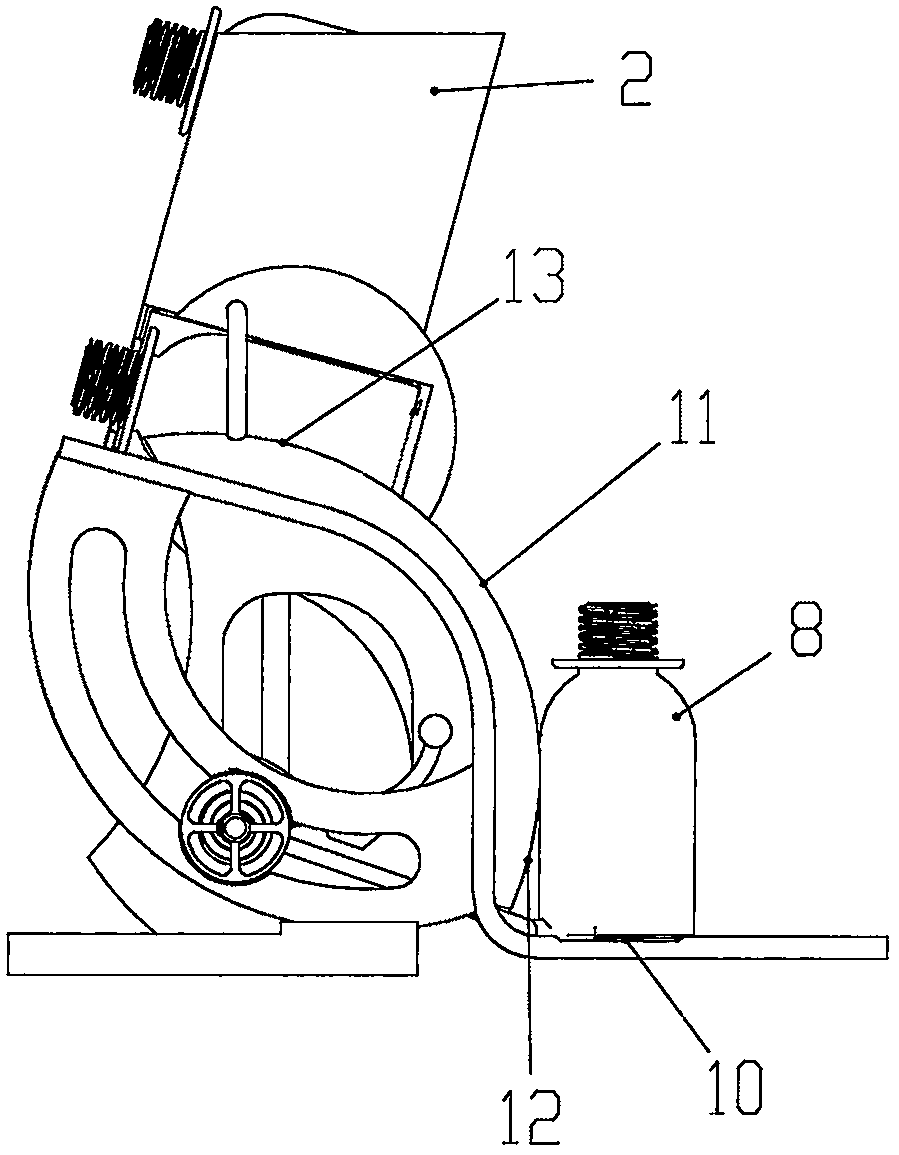

[0027] The embodiments of the present invention will now be described with reference to the accompanying drawings, in which similar element numbers represent similar elements. As mentioned above, the present invention provides a fully automatic bottle delivery line, which is used to transport the bottles from the track to the filling position, and convert the bottles from the lying state to the standing state, so as to facilitate the filling; the bottle conveying process The action is simple, the positioning of the bottle is accurate, and the conveying of the bottle is smooth and stable.

[0028] figure 1 It is a schematic diagram of the structure when the bottles of the automatic bottle feeding line of the present invention move from the track to the cam turntable, figure 2 , 3 It is a schematic diagram of the structure when the bottles of the automatic bottle feeding line of the present invention are conveyed to the filling surface position on the cam turntable, Figure 4 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com