Nitrosofluoro rubber solution polymerization process

A technology of nitrosofluororubber and polymerization process, which is applied in the field of organic fluorine chemistry, can solve the problems of inconvenient preparation of irregularly shaped sealing parts, single product form, single molding method, etc., and achieve the effect of superior synthesis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

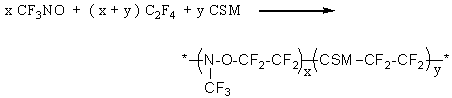

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Synthesis of solid-state nitrosofluororubber

[0044] Replace the stainless steel polymerization kettle with nitrogen and then evacuate it, and circulate the ethanol of -60°C as a cold medium in the jacket, and cool the empty kettle to -60°C; use the vacuum state of the polymerization kettle to add γ-nitroso in sequence by suction Base perfluorobutyric acid 100g, dichloromethane 3.5 liters; Start the polymerization kettle to stir, continue to circulate the cold medium in the jacket, and control the temperature of the kettle below -45°C, add 3.0 nitrosotrifluoromethane in the gas phase kg, add 3.1 kg of tetrafluoroethylene in the gas phase when the kettle temperature is lower than -50°C.

[0045] After the feeding was completed, the temperature of the polymerization kettle was allowed to rise naturally. When the temperature in the kettle rose to -45°C, the polymerization reaction started and released heat, and the initial pressure reached 0.62MPa. The reactio...

Embodiment 2

[0046] Example 2 Synthesis of semi-solid nitrosofluororubber

[0047] Replace the stainless steel polymerization kettle with nitrogen and then evacuate it, and circulate the ethanol as a cold medium at -70°C in the jacket, and cool the empty kettle to -60°C; use the vacuum state of the polymerization kettle to add γ-nitroso in sequence by suction Base perfluorobutyric acid 100g, molecular chain transfer agent ethyl ether 68g, dichloromethane 3.5 liters; start the polymerization kettle to stir, continue to circulate the cold medium in the jacket, and control the temperature of the kettle below -45°C, and add 1.6 kg of nitrosotrifluoromethane; 1.93 kg of tetrafluoroethylene was added in the gas phase when the kettle temperature was lower than -50°C.

[0048] After the feeding was completed, the temperature of the polymerization kettle was allowed to rise naturally. When the temperature inside the kettle rose to -45°C, the polymerization reaction started and released heat, and ...

Embodiment 3

[0049] Example 3 Synthesis of liquid nitrosofluororubber

[0050] Basically the same as Example 2, on this basis, sequentially add 100 g of γ-nitroso perfluorobutyric acid, 175 g of molecular chain transfer agent ether, and 3.5 liters of methylene chloride; Add 1.95 kg of nitrosotrifluoromethane; add 2.38 kg of tetrafluoroethylene in the gas phase under the condition that the temperature of the kettle is lower than -50°C.

[0051] After 18 hours of polymerization reaction, the solvent dichloromethane and the liquid polymer were taken out by liquid separation. After the polymer is washed with water, dehydrated, and low-molecular weight is removed, 2.48 kg of raw rubber is obtained as a light yellow transparent liquid. After testing, its intrinsic viscosity is 0.06 / dLg -1 , the acid content is 1.36% (mol), and the dynamic viscosity is 61Pa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com