Vehicle wheel hub assembly

A wheel hub and assembly technology, which is applied in the field of vehicle front suspension and front axle structure, can solve the problems of high cost and large index of wheel bolts, and achieve the effect of avoiding looseness and facilitating installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

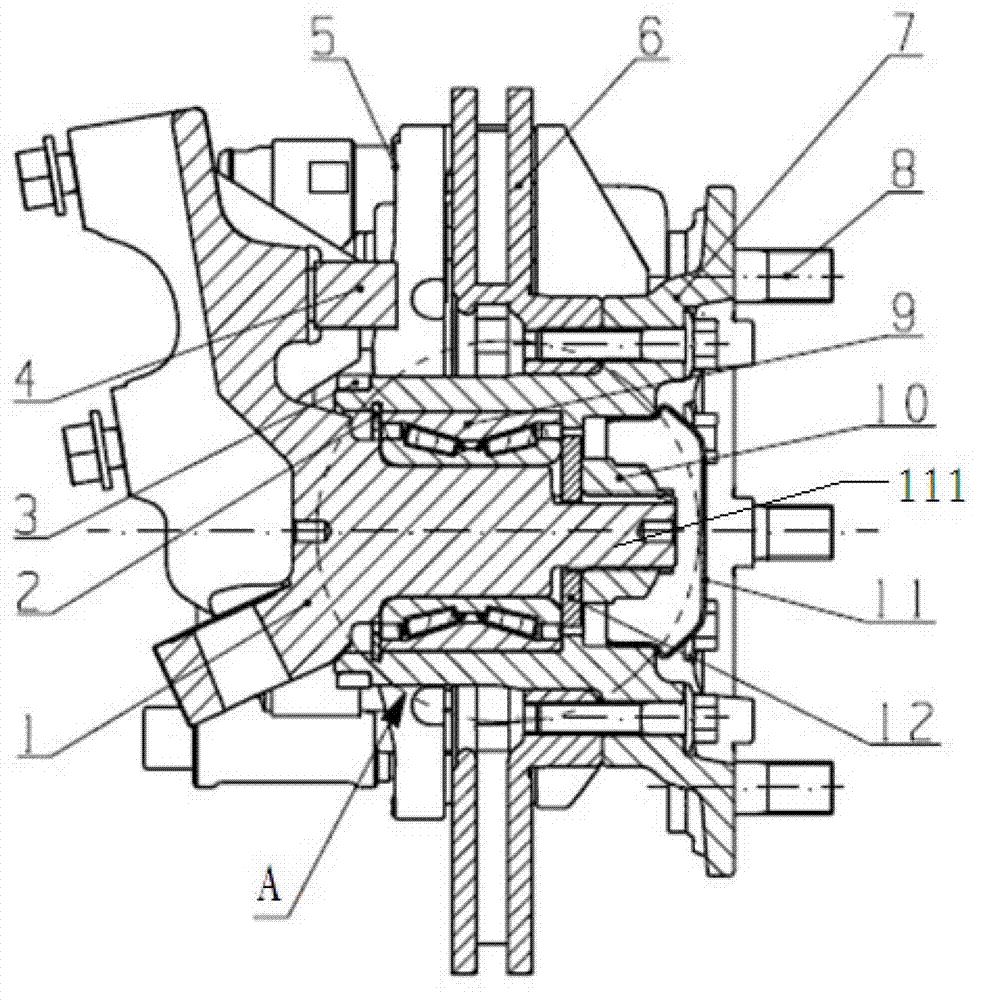

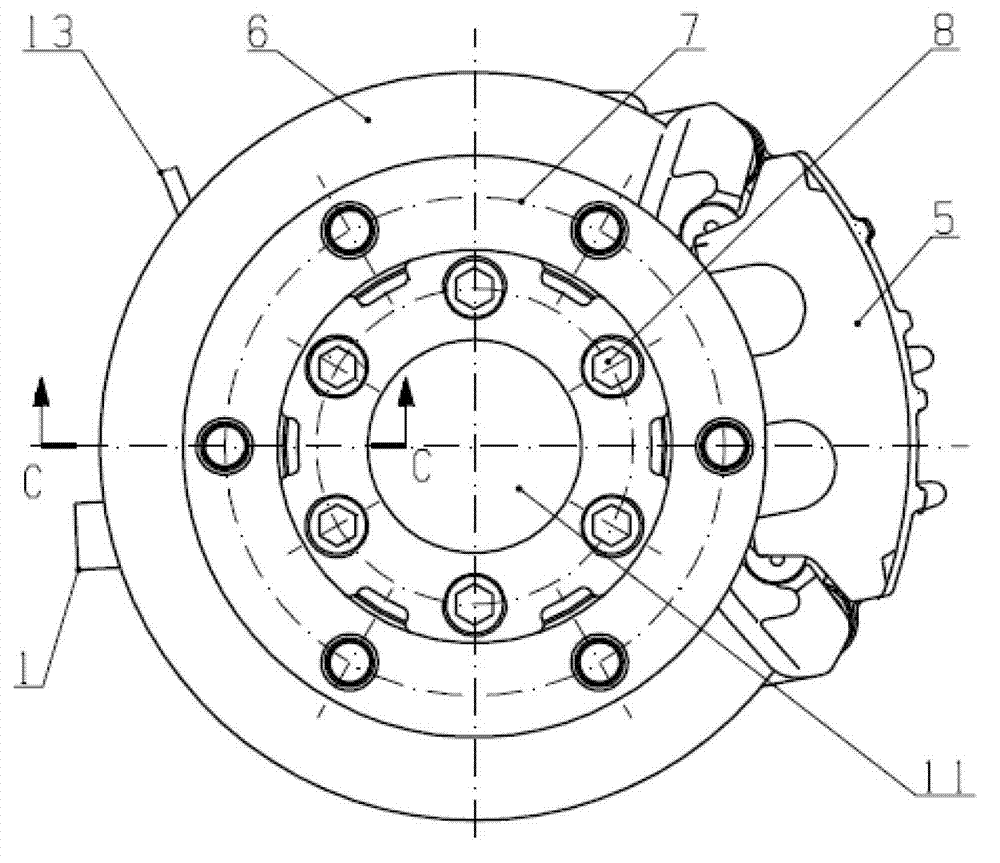

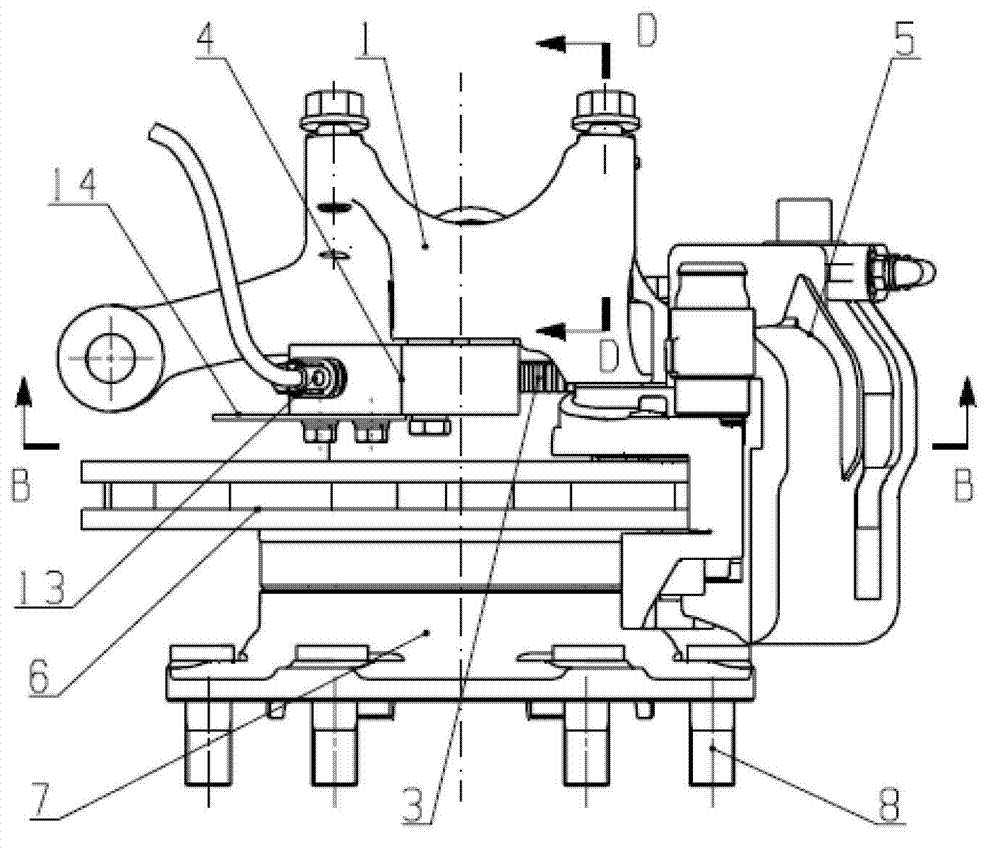

[0024] refer to figure 1 , figure 2 , image 3 , Figure 6 , the invention discloses a wheel hub assembly for a vehicle, especially a disc-type wheel hub assembly, which includes a steering knuckle 1, a snap spring 2, an ABS ring gear 3, an ABS sensor bracket 4, and a brake caliper assembly 5 , Brake disc 6, wheel hub 7, wheel bolt 8, double row tapered roller bearing 9, lock nut 10, hub cover 11, positioning retaining ring 12, ABS sensor 13, heat shield 14, etc.

[0025] After the double-row tapered roller bearing 9 is pressed into the hub inner cavity of the hub 7 with an air press, the circlip 2 is installed in the radial circular groove provided on the hole wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com