An external sound field type titanium alloy manual welding device and welding method

A manual welding and titanium alloy technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complicated operation and poor connection effect, and achieve strong process adaptability, reduced grain size, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings.

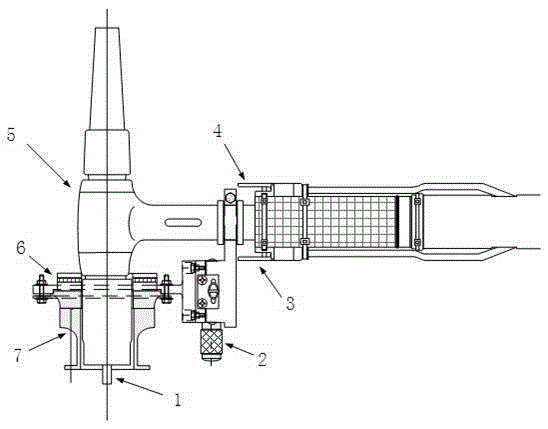

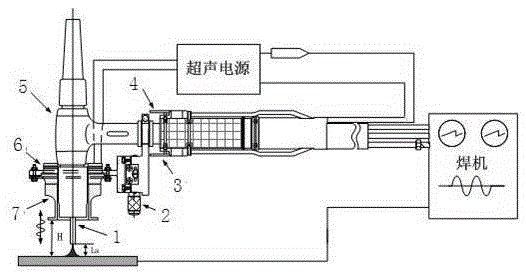

[0018] As shown in the figure, an external sound field type titanium alloy manual welding device includes a handheld TIG welding gun 5, an ultrasonic vibrating body composed of an ultrasonic transducer 6 and an ultrasonic horn 7, which is characterized in that the ultrasonic transducer 6 and The ultrasonic vibrating body composed of the ultrasonic horn 7 is sleeved at the ceramic nozzle at the front end of the TIG welding torch 5 through the central hole. The TIG welding torch 5, the ultrasonic transducer 6 and the ultrasonic horn 7 are coaxial lines, and the end of the TIG welding torch 5 is shrunk. In the ultrasonic horn 7, the end of the horn 7 is in a stepped shape to increase the radiation area. The welding gun 5 is equipped with a welding switch 4, an ultrasonic switch 3 and a fine-tuning mechanism 2. By triggering the ultrasonic switch 3, the opening and closing of the air rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com