Quick correction method for galvanometer correction system

A correction system and correction method technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of time-consuming, labor-intensive and cost-intensive galvanometer correction system, and achieve fast and convenient galvanometer correction, good technical effect, and time saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

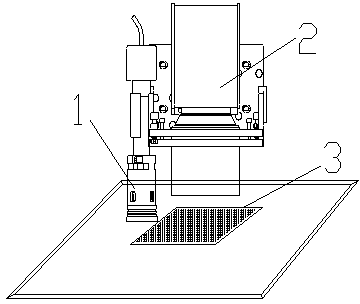

[0028] A galvanometer correction system, comprising a galvanometer correction plate, a galvanometer scanning module, a CCD image acquisition device, and an image processing module; the galvanometer scanning module controls the laser to form a matrix target on the galvanometer correction plate; the CCD image acquisition device Image acquisition is performed on the matrix target on the galvanometer correction board, and the image processing module processes the matrix target collected by the CCD image acquisition device, and then outputs a galvanometer compensation file to calibrate the galvanometer.

[0029] The quick correction method of described vibrating mirror correction system, comprises the following steps:

[0030] a) CCD correction, cut a circular hole with a diameter of 1mm on the galvanometer correction plate, move the CCD to the small circle position, move the machine so that the CCD captures the center of the circle, calculate the CCD Offset value, and input it to t...

Embodiment 2

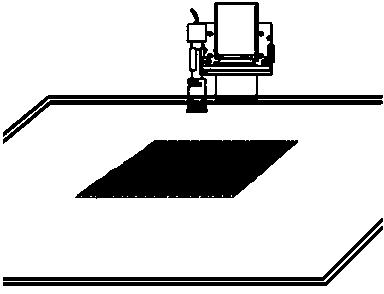

[0035] A vibrating mirror correction system, as attached figure 1 As shown, it includes: a galvanometer correction plate (clean and flat paper is enough), the laser is controlled by the galvanometer scanning module to form a matrix target on the galvanometer correction plate; a CCD image acquisition device is used to scan the galvanometer The matrix target on the correction board is used for image acquisition; the image processing module is used to process the matrix target collected by the CCD image acquisition device, and then output the galvanometer compensation file to calibrate the galvanometer.

[0036] The specific correction method is as follows:

[0037] 3. CCD correction: Cut a small circle (such as a circle with a radius of 0.5mm) on the galvanometer correction plate, move the CCD to the position of the small circle, move the machine so that the CCD captures the center of the circle, calculate the CCD Offset value and input it to the control System, so far, CCD cal...

Embodiment 3

[0042] A vibrating mirror correction system, as attached figure 1 As shown, it includes: a galvanometer correction plate (clean and flat paper is enough), the laser is controlled by the galvanometer scanning module to form a matrix target on the galvanometer correction plate; a CCD image acquisition device is used to scan the galvanometer The matrix target on the correction board is used for image acquisition; the image processing module is used to process the matrix target collected by the CCD image acquisition device, and then output the galvanometer compensation file to calibrate the galvanometer.

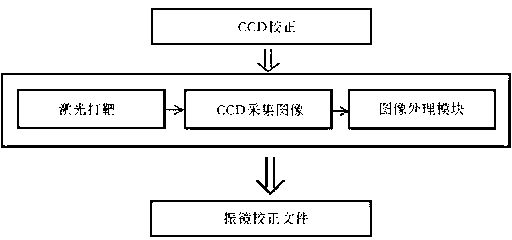

[0043] The method of galvanometer correction using the above galvanometer correction system is as follows: figure 2 As shown, the steps are as follows:

[0044] CCD correction: Cut a small circle (for example, a circle with a radius of 0.5mm) on the galvanometer correction plate, move the CCD to the position of the small circle, move the machine so that the CCD captures the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com