Asymmetric oxidation-resistant permeable membrane and preparation method thereof

A permeable membrane, oxidation-resistant technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of reducing surface hydrophilicity, reducing water flux, etc. Stable operation and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

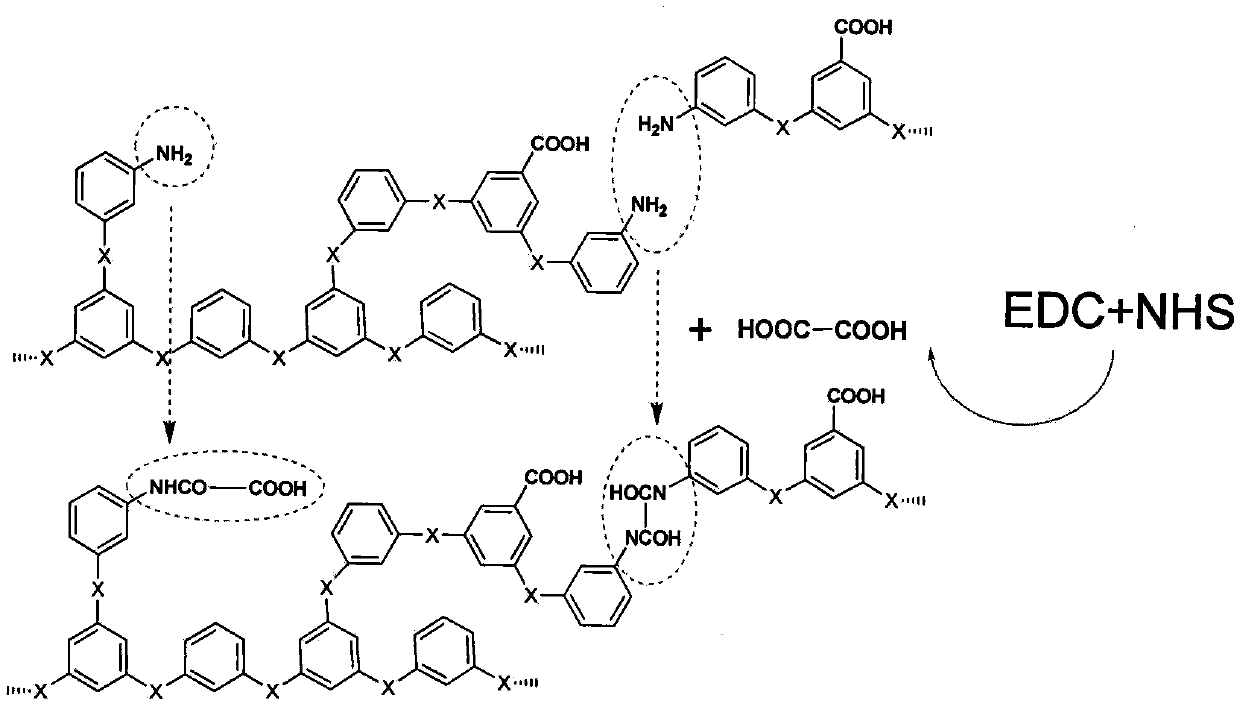

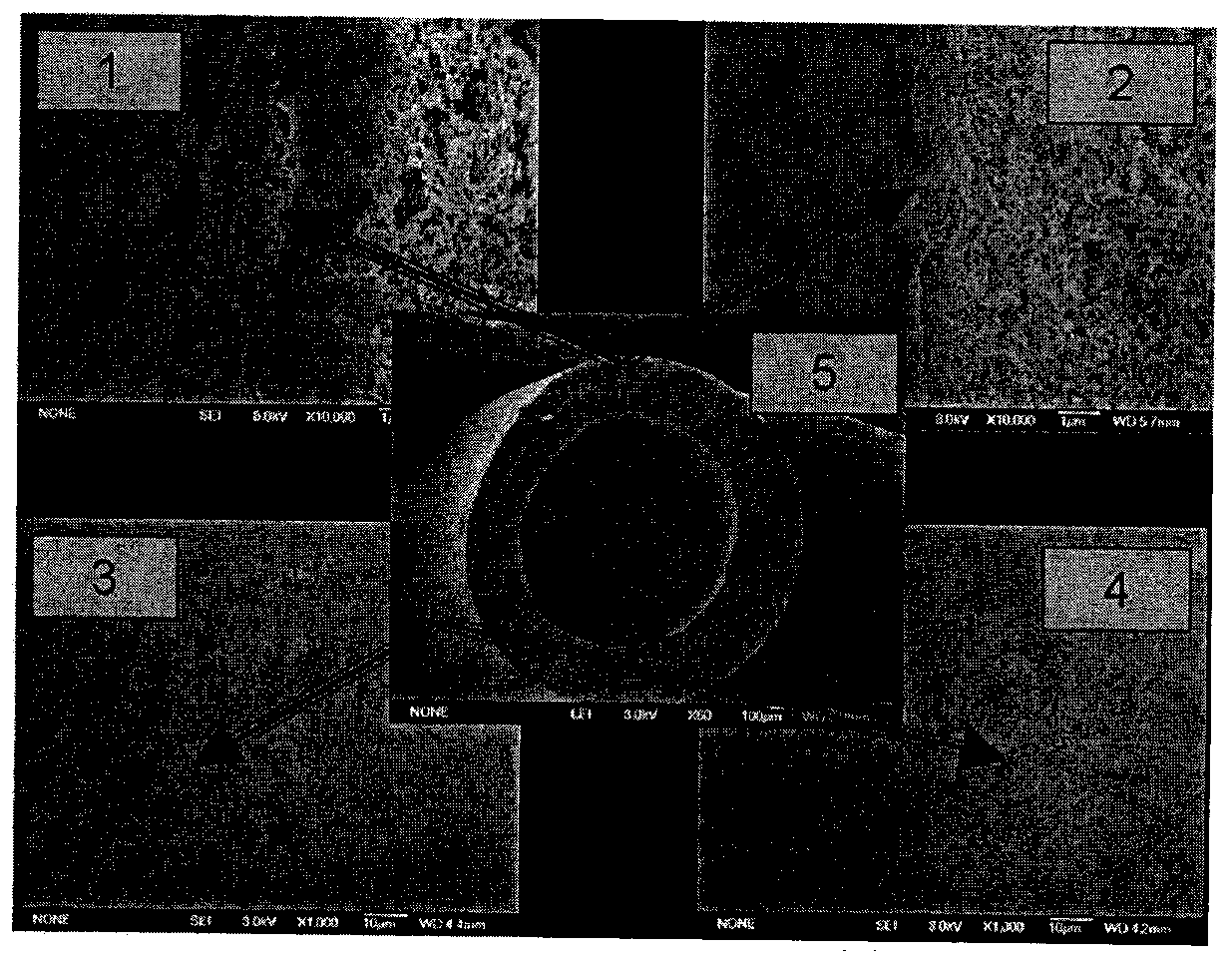

Method used

Image

Examples

Embodiment 1

[0024] The NaCl aqueous solution with a concentration of 2M is used as the drawing solution, and the secondary water is used as the raw material solution to test the water flux and rejection rate of the sample as a forward osmosis membrane. First, the prepared hollow fiber permeable membrane was placed in a self-made detection device for forward osmosis test. At room temperature (23°C), a certain flow rate was adjusted and controlled to keep the water flow pressure at 0.1 MPa, and the positive osmosis test was performed using an AY220 electronic balance. The mass of feed solution consumed by the membrane. Measure the mass change every 1 minute, and calculate the water permeation per unit area and unit time of the forward osmosis membrane, which can reach a maximum of 40L / (m 2 h). The DDS-307 conductivity meter was used to test the concentration change before and after the draw solution, and the interception rate of the permeable membrane for salt ions was calculated. The per...

Embodiment 2

[0026] MgCl at a concentration of 2M 2 The aqueous solution is the drawing liquid, and the secondary water is used as the raw material liquid, and the test sample is used as the water flux and rejection rate of the forward osmosis membrane. Put the prepared hollow fiber forward osmosis membrane in a self-made detection device for forward osmosis test. At room temperature (23°C), adjust and control a certain flow rate to keep the water flow pressure at 0.1MPa, and use an electronic balance to test the forward osmosis membrane. The consumption quality of the raw material solution. Measure the mass change every 1 minute, and calculate the water permeation per unit area and unit time of the forward osmosis membrane, which can reach a maximum of 52L / (m 2 h). The DDS-307 conductivity meter was used to test the concentration change before and after the draw solution, and the interception rate of the permeable membrane for salt ions was calculated. Oxalic acid treated permeable mem...

Embodiment 3

[0028] A NaCl aqueous solution with a concentration of 0.6M was used to simulate seawater, and a pressure-damped osmosis (PRO) power generation system was constructed with river water as the infiltrate, and the water flux and rejection rate of the sample as a forward osmosis membrane were tested. First place the prepared hollow fiber permeable membrane in the PRO performance testing device. At room temperature (23°C), adjust the size of the valve to control a certain flow rate, and use an electronic balance to test the consumption quality of the raw material solution passing through the forward osmosis membrane. Measure the mass change every 1 minute, and calculate the water permeation per unit area and unit time of the forward osmosis membrane, which can reach a maximum of 100L / (m 2 h). Use the DDS-307 conductivity meter to test the concentration change in front of the draw solution, and calculate the interception rate of the permeable membrane for salt ions. The permeable m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com