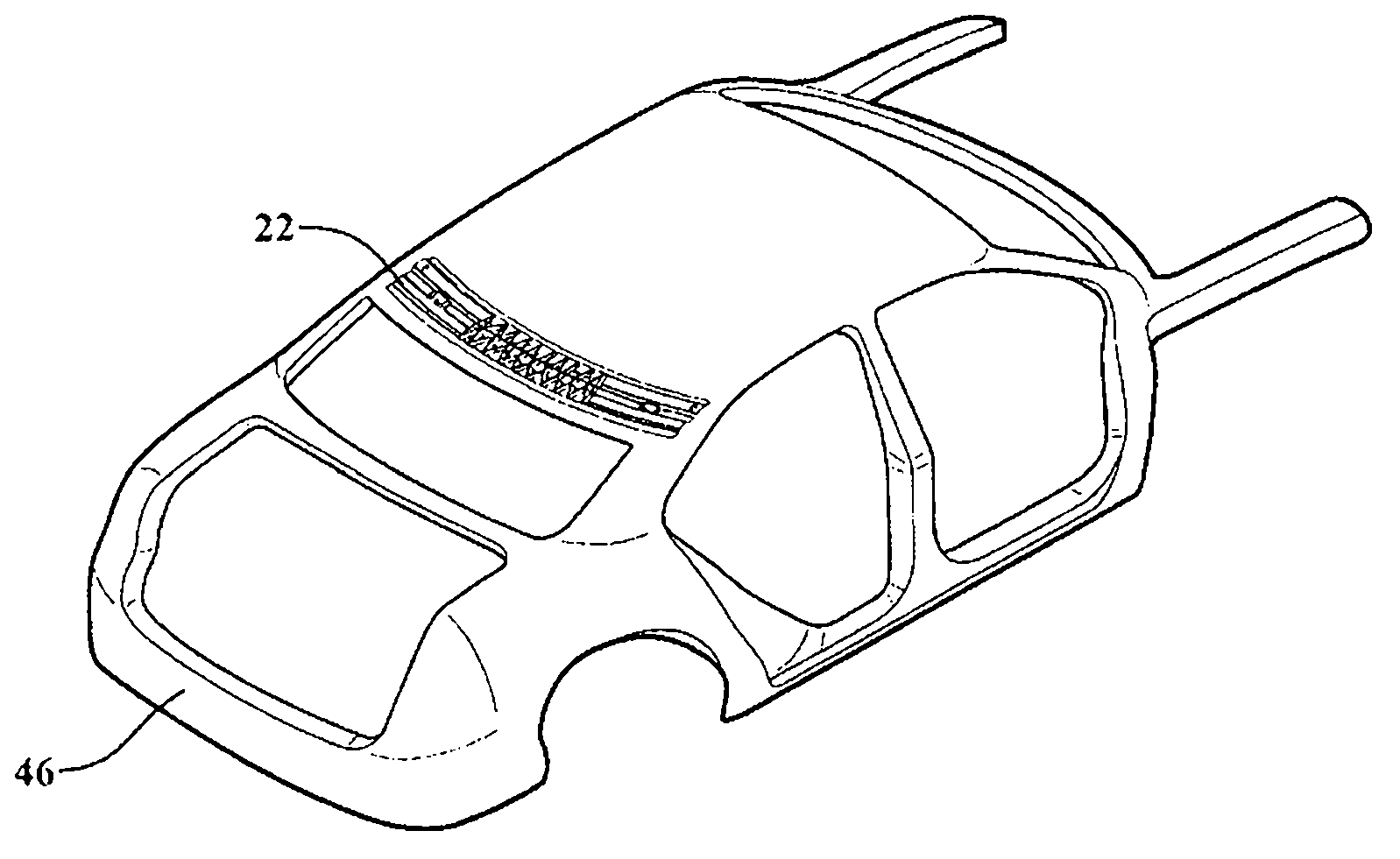

Roof bow

A technology of polymer and bow beam, applied in the direction of upper structure, vehicle parts, upper structure sub-assembly, etc., can solve problems such as incompatibility, reduce vibration and harsh sound, maintain structural strength and integrity, and improve fuel The effect of economy and energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0078] Evaluation of the sum of displacements as a function of the length of multiple ribs:

[0079] According to the invention, a first series of top bows (bows 1-7) are formed. The bow 1-7 generally includes a body, a ridge and first, second and third grooves, as described above. The body has a thickness of about 0.75 (mm) and a length of about 1047 mm. The ridges have a height (and the first, second and third grooves have a depth) of approximately 18 mm. The bow 1-7 also includes a plurality of ribs disposed in the first and second slots. The body comprises steel as the metal and the ribs comprise nylon 6 as the polymer.

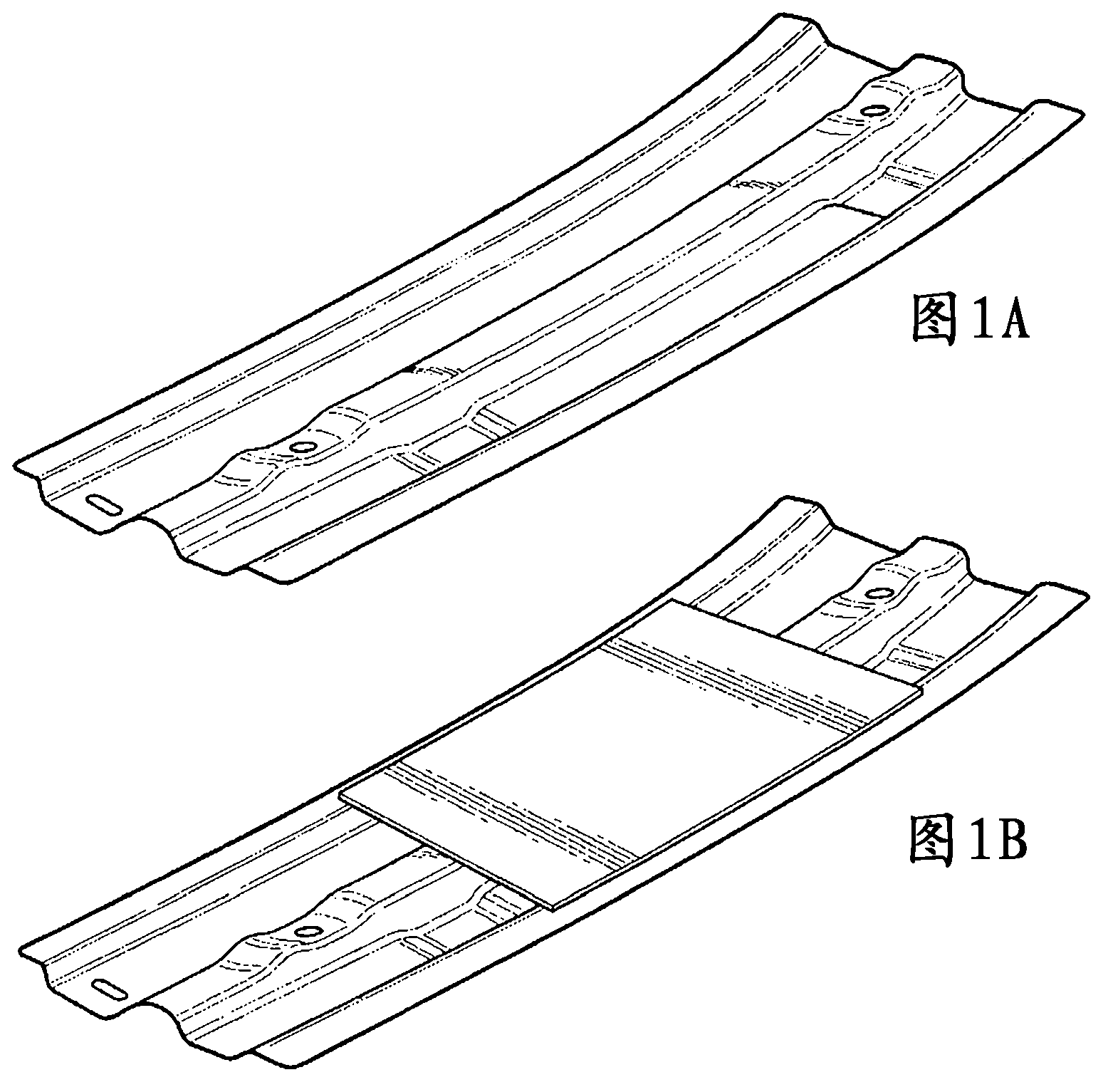

[0080] Two control beams (control arches 1 and 2) are also formed, but this is not according to the invention. Control bows 1 and 2 have the same shape, length, thickness and height as bows 1-7 and are formed from the same steel. However, the control arch 1 does not include any multiple ribs or any nylon 6, typically as Figure 1A shown. The control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com