Method and system for controlling a filter

A filter and suction pipe technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve problems such as reduced generator efficiency and reduced compressor performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

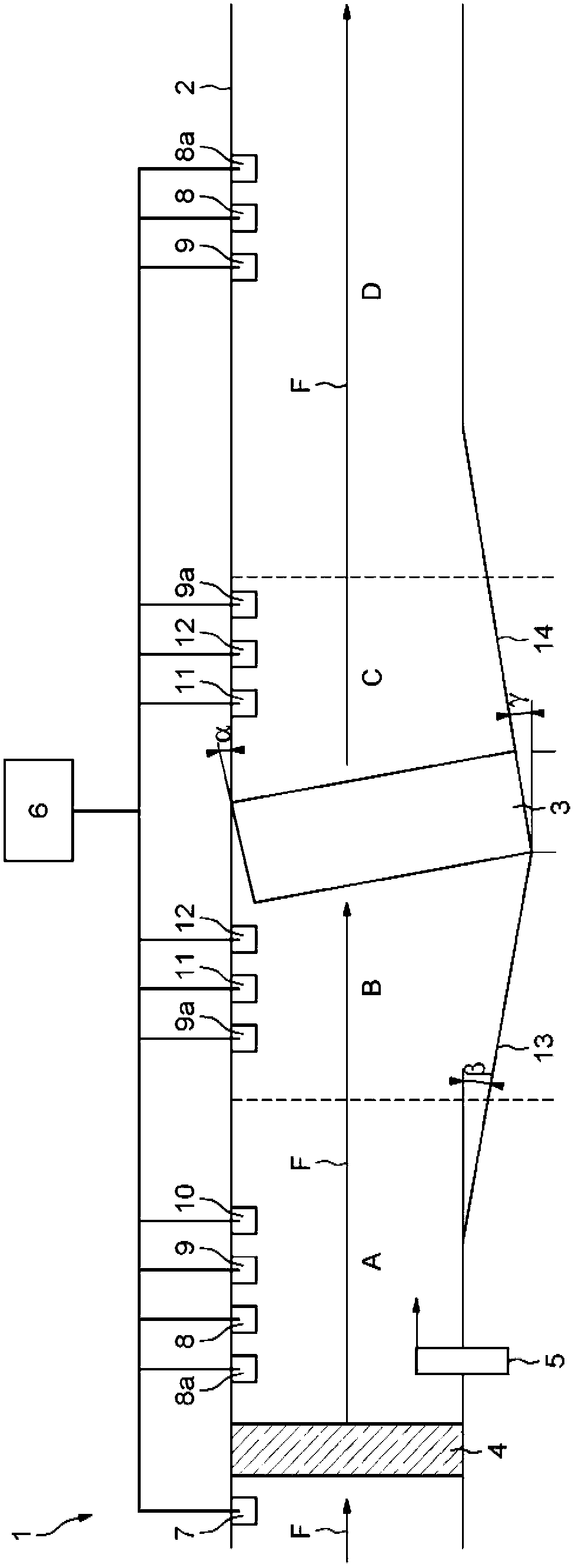

[0024] As shown in the drawings, the monitoring system 1 includes a test pipeline 2 in which a filter 3 to be tested is installed and in which a test procedure is carried out to determine the salt retention capacity of the filter 3 . Thus, the test duct 2 has suitable supports (not shown) for the filter 3 to position the filter in the duct in transverse direction, in the path of the incident air flow indicated by the arrow F.

[0025] A high-performance filter 4 called a "High Efficiency Particulate Air (HEPA)" filter is installed at the inlet of the test duct 2 to supply high-quality air in the duct, especially in the different measurement areas A, B, C and D. Air. The measurement area A is located between the HEPA filter 4 and the filter 3 to be tested until it adjoins the area B located directly upstream of the filter 3 . Zone C is located directly downstream of filter 3 and zone D is located downstream of zone C. The test conduit 2 comprises means 5 for injecting a flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com