Bagasse pretreatment method

A sugarcane bagasse and pretreatment technology, applied in fermentation and other directions, can solve problems such as waste of resources, high content of fermentation inhibitors, pollution, etc., and achieve the effects of reducing pretreatment costs, high reducing sugar yield, and high enzymatic hydrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the pretreatment method of bagasse, concrete operations are as follows:

[0037] (1) After drying 40g of bagasse at 80°C for 48 hours, crushing and sieving to obtain raw materials with a particle size of 18-40 mesh;

[0038] (2) Add bagasse to NaOH and H 2 o 2 In the mixed aqueous solution, at 42°C, 150rpm shaker pretreatment for 24h, wherein the final concentration of NaOH in the mixed aqueous solution is 1.0%, H 2 o 2 The final concentration in the mixed aqueous solution is 1.0%, and the mass volume (w / v) ratio of the mixed aqueous solution to bagasse is 15:1;

[0039] (3) Filter the pretreated bagasse, wash the filter residue with distilled water at 65°C until the filtrate is 7.0, and dry at 60°C to constant weight to obtain the pretreated bagasse for later use.

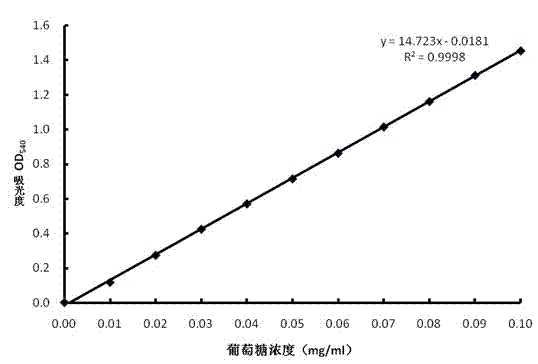

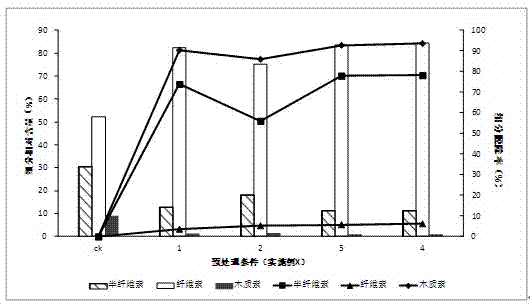

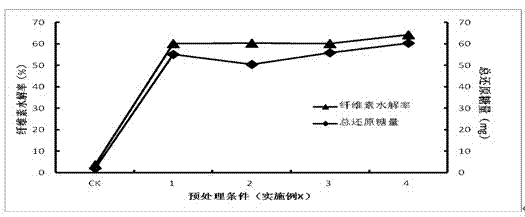

[0040] Put the dried, pulverized and sieved untreated bagasse samples and pretreated bagasse samples at 80°C to dry to constant weight, and conduct cellulose, semi For the determination o...

Embodiment 2

[0044] Embodiment 2: the pretreatment method of bagasse, concrete operations are as follows:

[0045] (1) After drying 40g of bagasse at 90°C for 54 hours, crushing and sieving to obtain raw materials with a particle size of 18-40 mesh;

[0046] (2) Add bagasse to NaOH and H 2 o 2 The mixed aqueous solution was added to the bagasse, and pretreated at 30°C with a 100rpm shaker for 12h, wherein the final concentration of NaOH in the mixed aqueous solution was 3.0%, H 2 o 2 The final concentration in the mixed aqueous solution is 1.0%, and the mass ratio of the mixed aqueous solution and bagasse is 20:1;

[0047] (3) Filter the pretreated bagasse, wash the filter residue with distilled water at 60°C until the filtrate is 6.5°C, and dry at 75°C to constant weight to obtain the pretreated bagasse for later use.

[0048] Detect by the detection method of embodiment 1: the relative content of cellulose, hemicellulose and lignin in the untreated bagasse raw material is respective...

Embodiment 3

[0049] Embodiment 3: the pretreatment method of bagasse, concrete operations are as follows:

[0050] (1) After drying 40g of bagasse at 85°C for 60 hours, crushing and sieving to obtain raw materials with a particle size of 18-40 mesh;

[0051] (2) Add bagasse to NaOH and H 2 o 2 The mixed aqueous solution was added to the bagasse, and pretreated at 35°C with a 200rpm shaker for 36h, wherein the final concentration of NaOH in the mixed aqueous solution was 1.0%, H 2 o 2 The final concentration in the mixed aqueous solution is 1.5%, and the mass ratio of the mixed aqueous solution and bagasse is 20:1;

[0052] (3) Filter the pretreated bagasse, wash the filter residue with distilled water at 65°C until the filtrate is neutral, and dry at 70°C to constant weight to obtain the pretreated bagasse for later use.

[0053] Detected according to the detection method of Example 1: the relative content of cellulose, hemicellulose and lignin in the untreated bagasse raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com