A method for separating and purifying m-cresol from m-p-mixed cresol

A technology of mixing cresol and m-cresol, which is applied in the field of separation and purification of m-cresol, can solve the problems of high energy consumption, and achieve the effect of reducing energy consumption and solvent usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

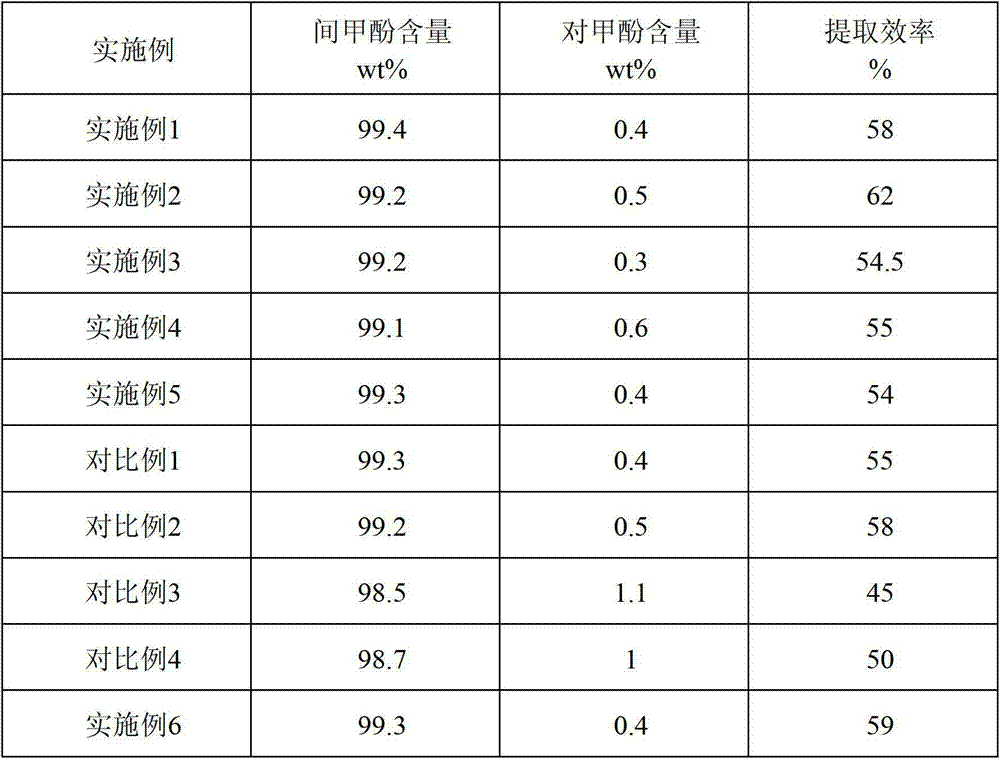

Examples

Embodiment 1

[0019] Add raw material industrial m-cresol (purchased from Xingtai Xuyang Coal Chemical Co., Ltd.), m-cresol (57.9wt%), p-cresol (27.7wt%), 2,4‐xylenol in the reaction kettle (7.6wt%), 2,5-xylenol (4.9wt%), also contains part of o-cresol, phenol and 2-ethylphenol, when adding complexing agent urea, its addition is the same as that of raw material m-cresol The ratio is 0.6:1, the oil bath is heated to 80°C, and the temperature is maintained for 60 minutes. After the reaction is completed, cool down naturally to 60°C, slowly add petroleum ether with a boiling range of 60-90°C, the volume ratio of the amount of petroleum ether to the raw material p-cresol is 2:1, and after the addition is complete, put the reaction solution in cold water at 4°C Bath for crystallization, maintained for 2 hours; filtered, cooled to 4 ° C boiling range 60-90 ° C petroleum ether washing, the amount is 2 times the volume of mixed cresol between raw materials; filtrate rectification recovery petroleum...

Embodiment 2

[0022] The experimental device and operation are the same as in Example 1, except that the amount of petroleum ether used for washing crystals with a boiling range of 60-90° C. is 1 times the volume of p-cresol between raw materials. The results are shown in Table 1.

Embodiment 3

[0024] The experimental device and operation are the same as in Example 1, except that petroleum ether uses a boiling range of 90-120°C. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com