Trans-electric-control dimming glass and manufacturing method and application thereof

A dimming glass, electronic control technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of inability to realize industrialization, no practical products, large mode power consumption, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

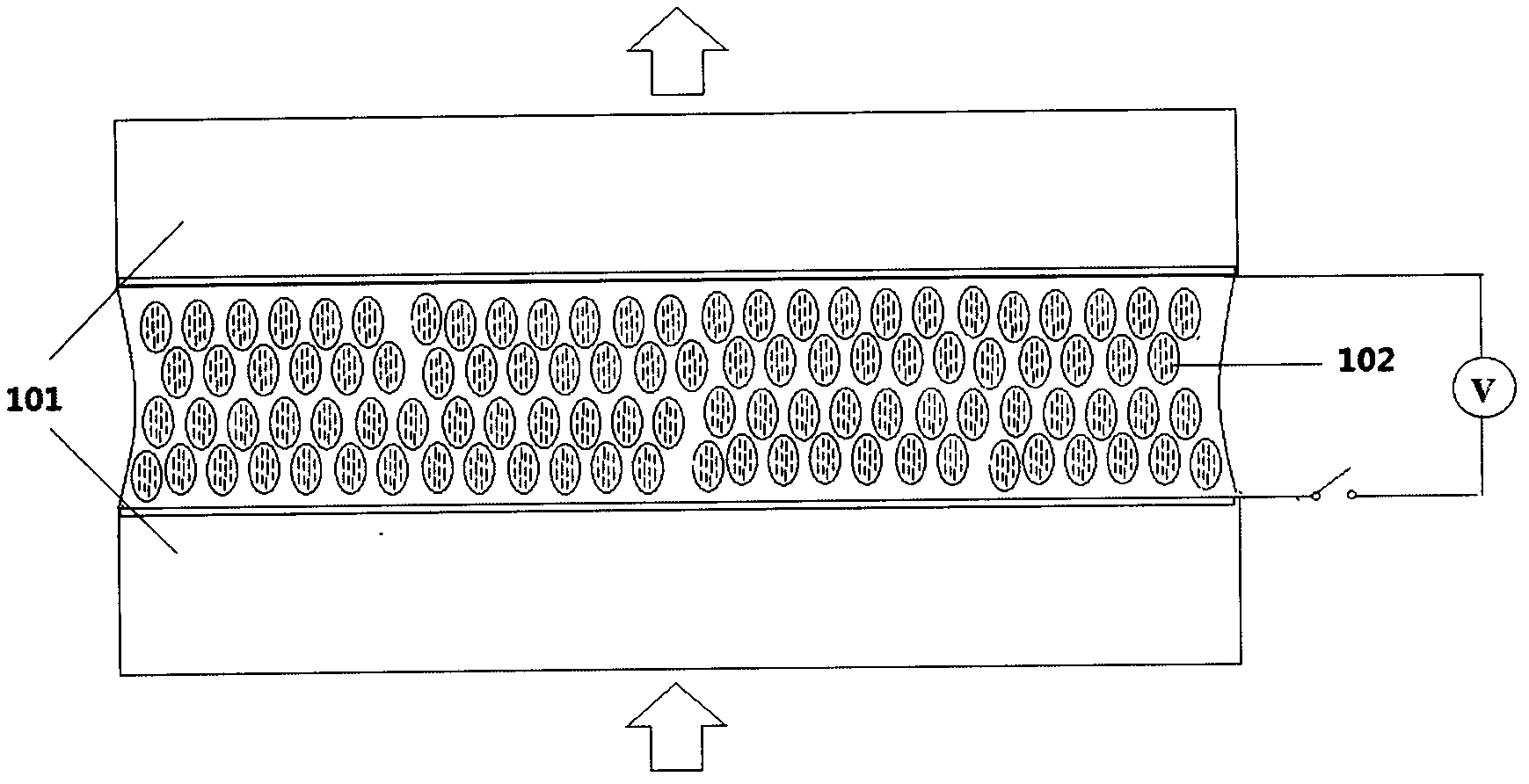

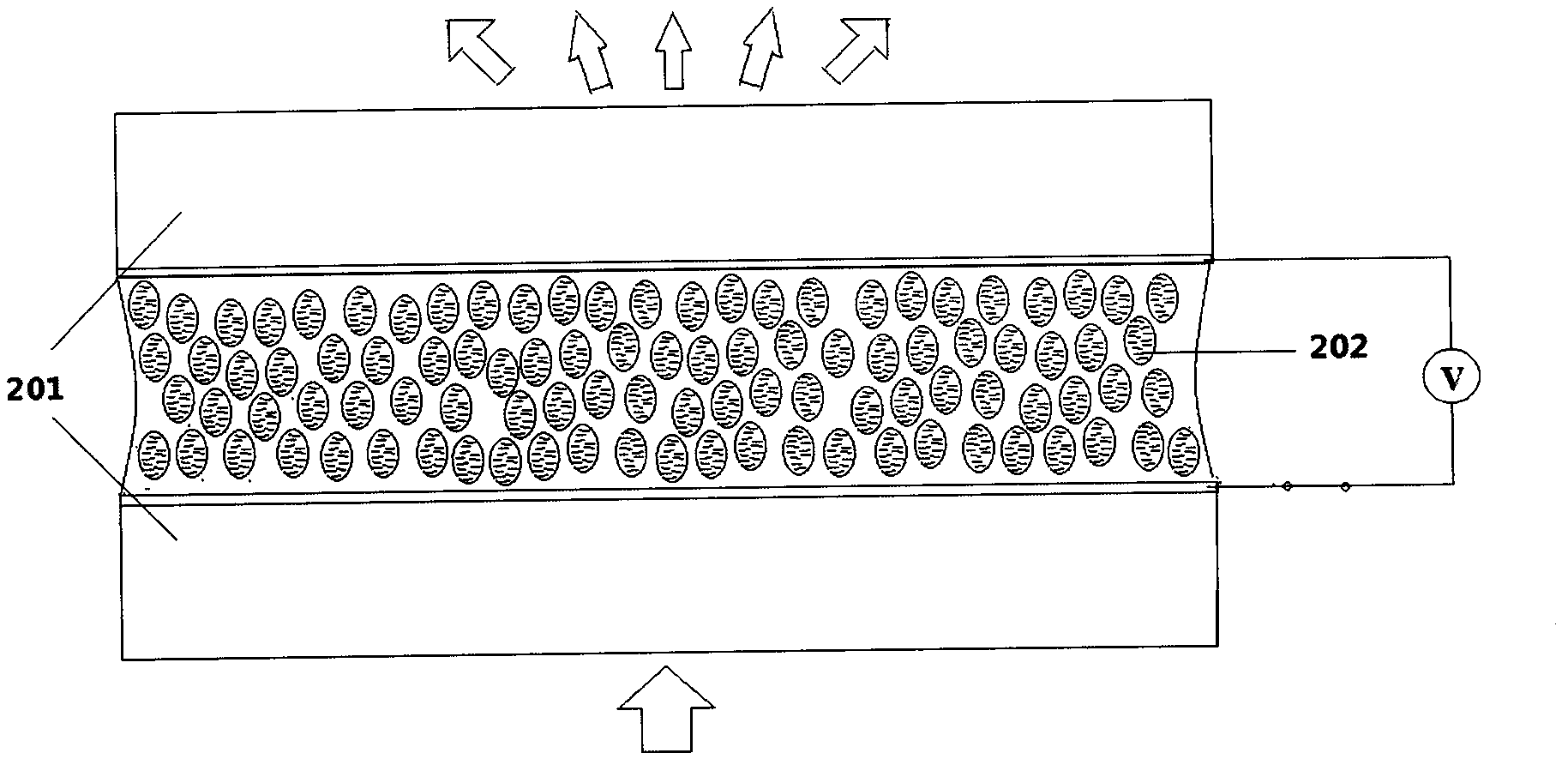

Image

Examples

Embodiment 1

[0039] Example 1, the polymer-dispersed negative liquid crystal trans-type electronically controlled dimming glass is manufactured in a clean workshop, and the steps of the preparation method are:

[0040] The first step is to prepare the prepolymer

[0041] With 20% alkoxynonyl acrylate, 70% trimethylolpropane triacrylate, 2% toughening agent nitrile rubber, 3% chain transfer agent 2-mercaptoethanol and 5% light Initiator 1173 prepares the prepolymer, stirs the mixture at room temperature for 2 minutes and mixes well, the refractive index of the prepolymer after curing is n p = 1.517.

[0042] The second step is to prepare liquid crystal glue

[0043] Mix the prepolymer configured in the first step with the nematic negative liquid crystal material (negative liquid crystal HNG720200-100 provided by Jiangsu Hecheng Display Technology Co., Ltd.) in a mass ratio of 1:1, and stir with a stirrer at room temperature Make it fully mixed for 2 minutes to form a liquid crystal glue,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com