Multifunctional turbofan jet engine

A technology of jet engines and turbofans, applied in the direction of machines/engines, jet propulsion devices, gas turbine devices, etc., can solve the problems of not being able to greatly increase and change speed, potential safety hazards, blade ablation, etc., to improve thermal management capabilities, Long service life and high thrust-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] At present, the existing Taihang and Kunlun aero-engines in China all use turbofan engines as prototypes.

[0044] Provide a non-limiting embodiment below in conjunction with accompanying drawing and further illustrate the present invention.

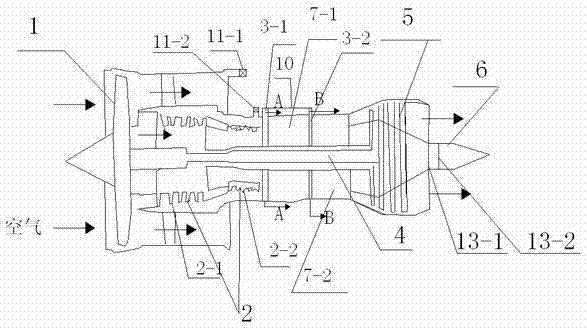

[0045] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a multifunctional turbofan jet engine includes: a fan 1 for inhaling air, a compressor 2 for performing work on the inhaled air, and a second combustion chamber 7-2 for igniting the gas that has performed work through the compressor , the turbine 5 and the exhaust pipe 6 which discharges the combusted gas, and also includes the first combustion chamber 7-1 arranged at the intake end of the second combustion chamber 7-2, wherein the first combustion chamber 7-1 and the second combustion chamber 7-2 are provided with a tubular combustion cylinder 8; the cylindrical outer covers of the first combustion chamber and the second combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com