Self-positioning quick segment erector

A segment assembling machine and self-positioning technology, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of limitation of segment posture adjustment, inflexible movement of rotating platform, influence of tunnel forming quality, etc. The efficiency of segment assembly, the high efficiency of segment assembly, and the flexibility of the grabbing head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

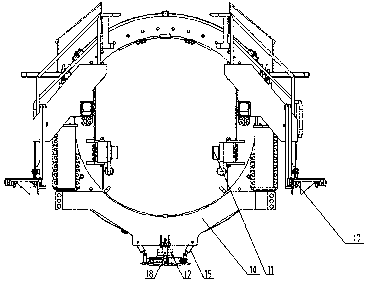

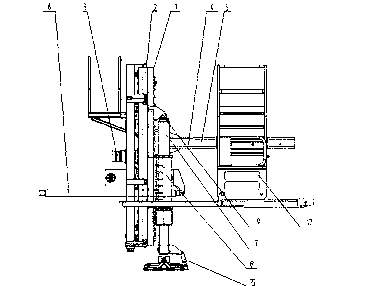

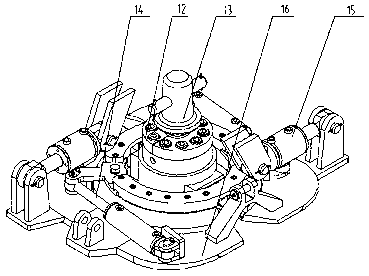

[0011] Referring to the accompanying drawings, the self-positioning fast segment assembly machine, the whole device consists of a rotating device 1, a fixing device 2, a driving device 3, a walking beam 4, a walking track 5, a translation cylinder 6, a moving sleeve 7, a fixed sleeve 8, and a lifting cylinder 9 , truss 10, guide wheel 11, grabbing device 12, extracting cylinder 13, locking cylinder 14, adjusting cylinder 15, positioning locking plate 16, mobile assembly platform 17, segment pressing plate 18, etc. The axial direction of the tunnel is set as the X axis, the radial horizontal direction of the tunnel is the Y axis, and the vertical direction of the tunnel radial direction is the Z axis. The axes of the rotating device 1 and the fixing device 2 coincide with the X axis, the driving device 3 is fixed on the fixing device 2, and its hydraulic motor drives the pinion through the reduction box, thereby driving the large ring gear and the rotating device 1 connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com