Method for shoring prestressed double-row-pile strong-constraint deep foundation pit

A deep foundation pit support, prestressed technology, applied in excavation, foundation structure engineering, water conservancy engineering, etc. To achieve the effect of improving the stability against overturning, reducing the distance between pile rows and increasing the anti-overturning moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

[0016] 1. Construction steps:

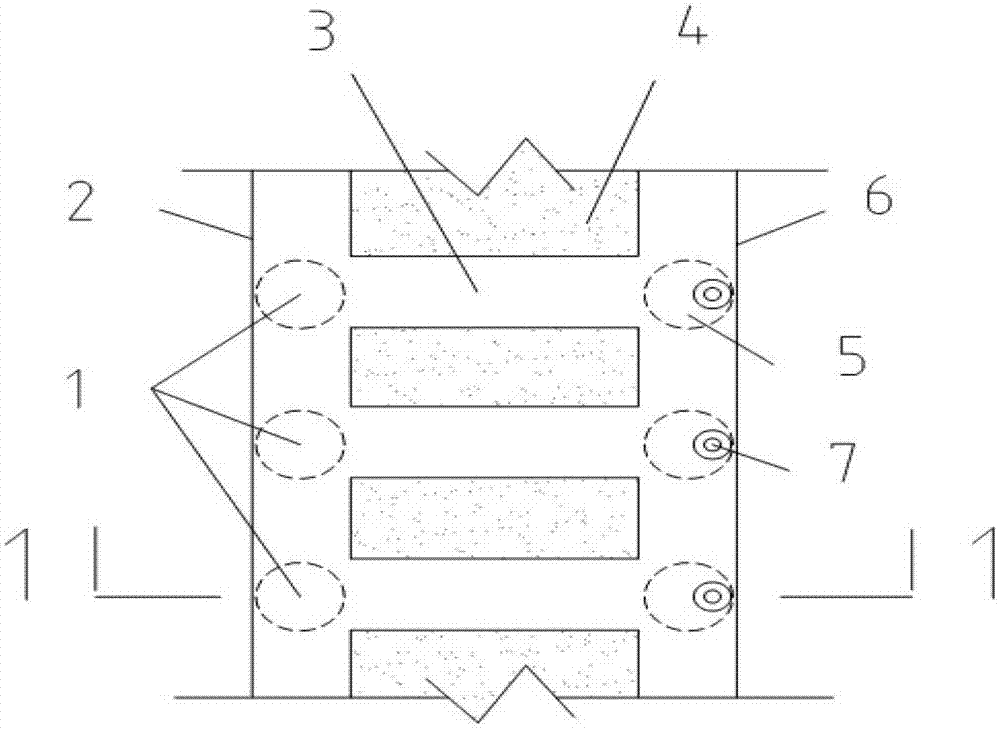

[0017] Arrange two rows of reinforced concrete cast-in-situ piles around the foundation pit to be excavated. The back row of piles 5 and the front row of piles 1 are separated by 3-5 times the pile diameter d, and the back row of piles 5 is 3-5m longer than the front row of piles 1. During the construction of the rear row of piles 5, the prestressed anchor cable 9 is divided into two parts: one part is the free section 10 of the anchor cable, which is triple-corroded with butter, film and bellows, and made to expand and contract freely; the other part is the anchor section 11 of the anchor cable. Without any treatment, the prestressed anchor cables 9 and the reinforcement cages 8 are tied together and then sent into the pile holes for grouting. The prestressed anchor cables are arranged in the direction close to the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com