Device for preventing billet from tipping in steel tapping and steel loading of hot rolling heating furnace and control method thereof

A heating furnace and anti-tipping technology, which is applied in the safety protection of hot-rolled heating furnace tapping and steel loading, the control of hot-rolled heating furnace tapping, the device, and the billet anti-tipping device in the steel loading process, which can solve the problem of reducing The service life of the heating furnace, the damage of peripheral equipment, and the poor environment of the processing process have achieved the effect of reducing the difficulty of troubleshooting, avoiding safety accidents, and shortening the processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

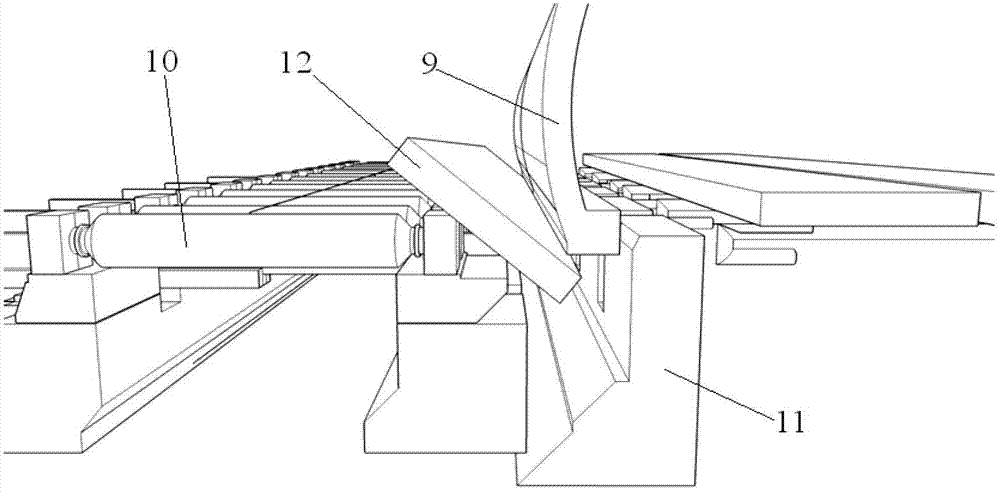

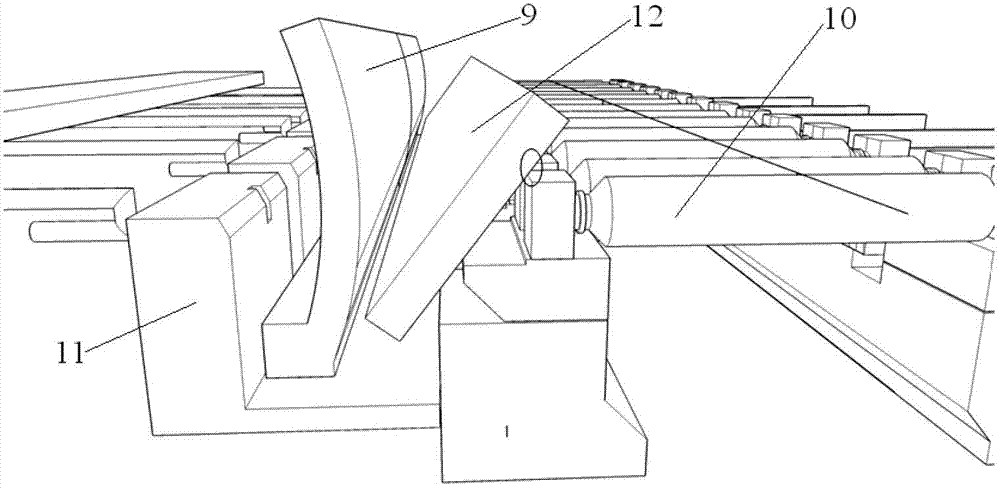

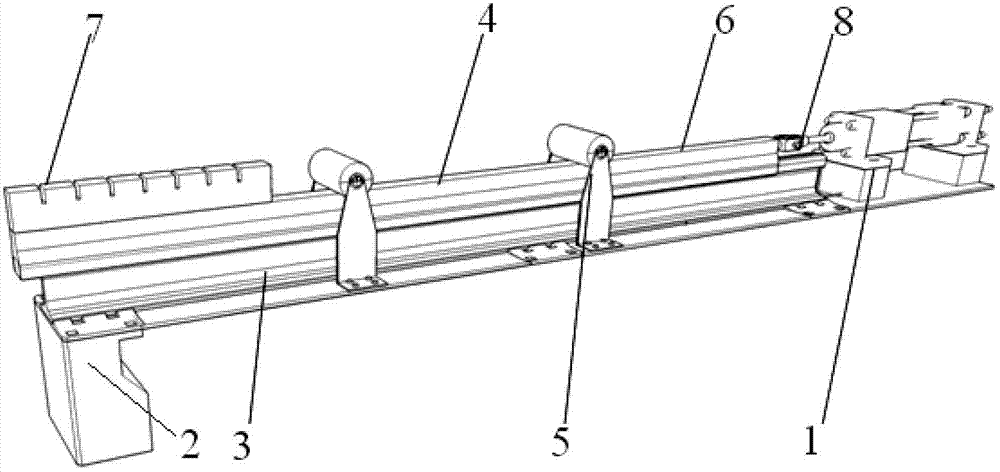

[0044] Such as Figure 3 to Figure 9 The structure of the present invention expressed is a billet anti-overturning device in the process of tapping and charging a hot-rolling heating furnace. The hot-rolling heating furnace includes a furnace door 9 and a furnace body 11 . Outside the furnace body 11, a roller table 10 for transporting a slab 12 is provided.

[0045] In order to solve the problems existing in the prior art and overcome its defects, and to realize the invention purpose of preventing the hot-rolled heating furnace from being loaded with steel and the billet from tipping during the tapping process, the technical schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com