Absorbent of naphthaline in coke oven gas and preparation method thereof

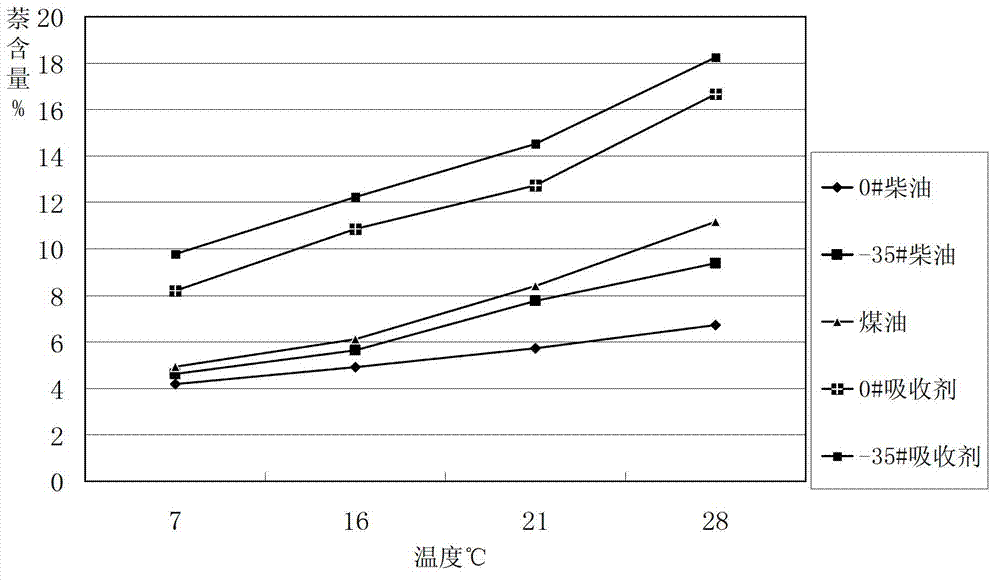

A technology for coke oven gas and absorbent, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve the problems of low naphthalene removal efficiency, difficulty in separating naphthalene from diesel oil, limited petroleum resources, etc., and achieves no process conditions The effect of restriction, high recycling value and abundant raw material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

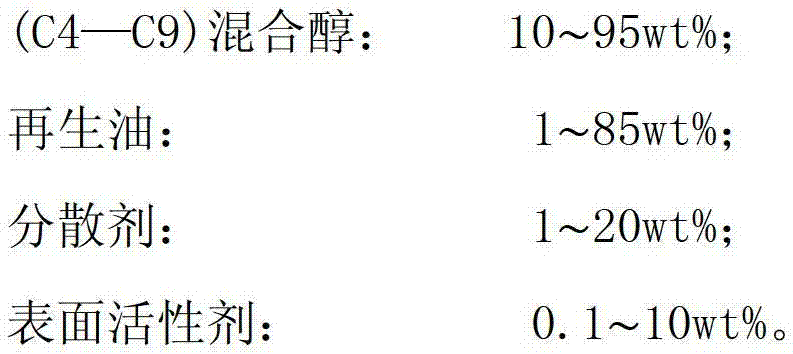

[0024] Add 90wt% (C4-C9) straight chain alcohol, 7wt% pyrolysis regenerated engine oil, 2wt% stearic acid and 1wt% cyclohexane into a stainless steel container under mechanical stirring, operating at -30 It is carried out within the range of ~40°C, and the material is discharged after stirring evenly to obtain an absorbent for naphthalene in coke oven gas.

Embodiment 2

[0026] Add 80wt% (C4-C9) straight-chain alcohol, 15wt% pyrolysis regenerated engine oil, 3wt% amide compound and 2wt% cyclohexane into a stainless steel container in turn under mechanical stirring, operating at -30 It is carried out within the range of ~40°C, and the material is discharged after stirring evenly to obtain an absorbent for naphthalene in coke oven gas.

Embodiment 3

[0028] Add 70wt% (C4-C9) straight-chain alcohol, 20wt% biofuel, 6wt% amides and 4wt% cyclohexane into a stainless steel container under gas stirring, and operate at a temperature of -30 ~ It is carried out within the range of 40°C, and the material is discharged after stirring evenly to obtain an absorbent for naphthalene in coke oven gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com