Urea-formaldehyde foam plastic insulation board and preparation method thereof

A technology of urea-formaldehyde foamed plastic and thermal insulation board is applied in the field of thermal insulation board and its preparation. The effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

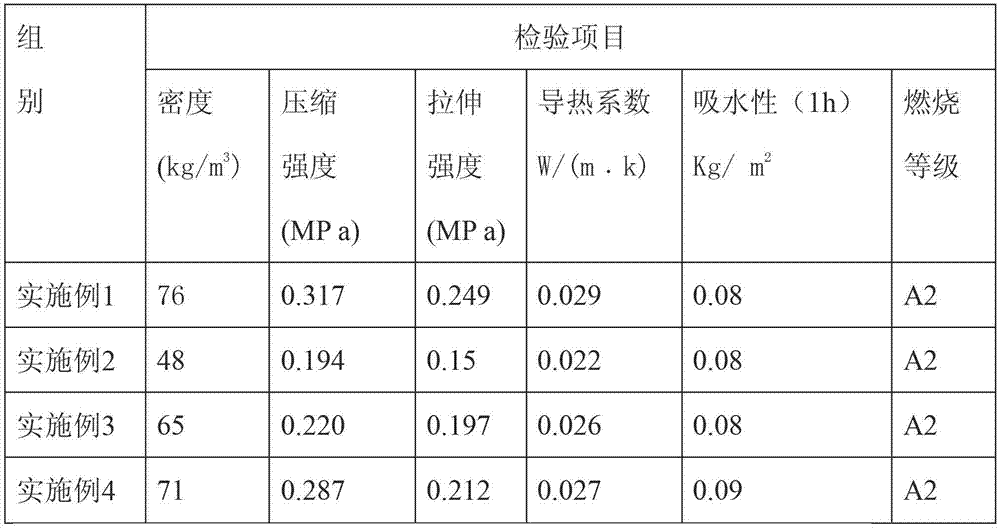

Examples

Embodiment 1

[0027] The urea-formaldehyde foam insulation board is made up of the following components in the following parts by weight ratio: urea-formaldehyde resin: sodium lauryl sulfate: phosphoric acid: urea: mica powder: expanded perlite: water=600:8:10: 6:80:80:300.

[0028] The mesh number of described mica powder is 300 mesh. The particle size of expanded perlite is 2mm.

[0029] The method for preparing urea-formaldehyde foamed plastic insulation board comprises the following steps:

[0030] (1) Take 8kg of sodium lauryl sulfate, 6kg of urea and 300kg of water to make foaming liquid;

[0031] (2) Take 600kg of urea-formaldehyde resin, 80kg of mica powder and 80kg of expanded perlite and mix them evenly to make a mixed raw material;

[0032] (3) Stir the foaming solution with a stirrer and then add the mixed raw materials to stir thoroughly;

[0033] (4) Add 10kg of phosphoric acid to mix and stir evenly, then pour into the mold to form, and after curing, release the mold and ...

Embodiment 2

[0035] The urea-formaldehyde foam plastic insulation board is composed of the following components in the following parts by weight:

[0036] Urea-formaldehyde resin: sodium lauryl sulfate: phosphoric acid: urea: mica powder: expanded perlite: water=700:5:8:3:50:50:200.

[0037] The mesh number of described mica powder is 450 mesh. The particle size of expanded perlite is 4mm.

[0038] The method for preparing urea-formaldehyde foamed plastic insulation board comprises the following steps:

[0039] (1) Take 5kg of sodium lauryl sulfate, 3kg of urea and 200kg of water to make foaming liquid;

[0040] (2) Take 700kg of urea-formaldehyde resin, 50kg of mica powder and 50kg of expanded perlite and mix them evenly to make a mixed raw material;

[0041] (3) Stir the foaming solution with a stirrer and then add the mixed raw materials to stir thoroughly;

[0042] (4) Add 8kg of phosphoric acid, mix and stir evenly, then pour into the mold for molding, and after curing, release th...

Embodiment 3

[0044] The urea-formaldehyde foam insulation board is made up of the following components in the following parts by weight ratio: urea-formaldehyde resin: sodium lauryl sulfate: phosphoric acid: urea: mica powder: expanded perlite: water=620:6:8: 4:70:65:220.

[0045] The mesh number of described mica powder is 400 mesh. The particle size of expanded perlite is 3mm.

[0046] The method for preparing urea-formaldehyde foamed plastic insulation board comprises the following steps:

[0047] (1) Take 6kg of sodium lauryl sulfate, 4kg of urea and 220kg of water to make foaming liquid;

[0048] (2) Take 620kg of urea-formaldehyde resin, 70kg of mica powder and 65kg of expanded perlite and mix them evenly to make a mixed raw material;

[0049] (3) Stir the foaming solution with a stirrer and then add the mixed raw materials to stir thoroughly;

[0050] (4) Add 8kg of phosphoric acid, mix and stir evenly, then pour into the mold for molding, and after curing, release the mold and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com