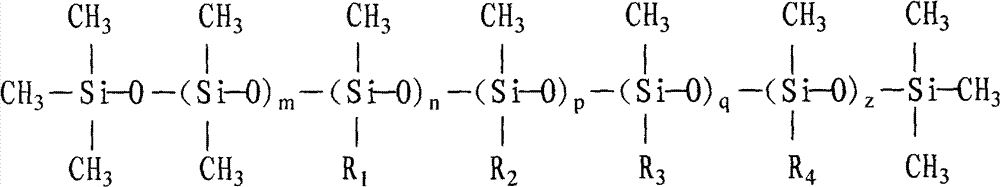

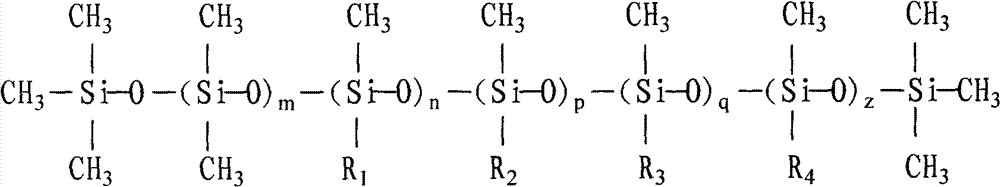

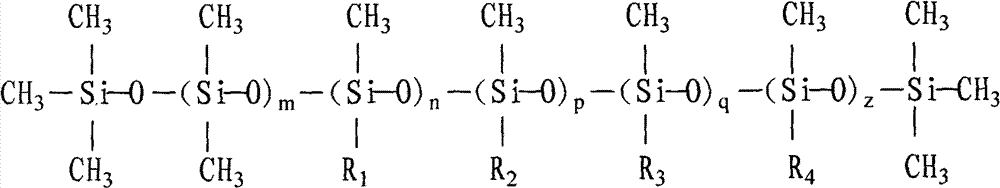

Hydrophilic aminosilicon oil, and preparation method and uses thereof

A technology of amino silicone oil and hydrophilic type, which is applied in the direction of fiber type, textile and paper making, fiber treatment, etc. It can solve the problems of reducing whiteness, poor antistatic property, and discoloration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add high hydrogen-containing silicone oil, D4, hexamethyldisilazane, and ammonia water in a ratio of 10:1:1.5:1 to the mouth of a three-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, stir, and heat up to 80 After reacting at ℃ for 3 hours, add sulfamic acid, continue to stir for 2 hours, and then carry out suction filtration, distillation, and removal of low boilers to obtain low-hydrogen silicone oil with an appropriate hydrogen content;

[0032] Add low-hydrogen silicone oil and D4 into the reaction kettle equipped with a stirrer, reflux condenser and thermometer in sequence at a ratio of 10:0.15, and pass N 2 Stir and heat up to 60°C, add zinc oxide, continue to stir, and react at a constant temperature of 110°C for 3 hours, the reaction solution becomes turbid and clear;

[0033] Then add methyltriethoxysilane and allyl polypropylene glycol into the reaction kettle in sequence at 1:10, keep the material reaction until transparent at 110...

Embodiment 2

[0042] Add high hydrogen-containing silicone oil, DMC, hexamethyldisilazane, and ammonia water in a ratio of 10:1:1.5:1 into the mouth of a three-necked flask equipped with a stirrer, reflux condenser, and thermometer, stir, and heat up to 80°C React for 3 hours, add neutralizing agent with zinc oxide, continue to stir for 2 hours, carry out suction filtration, distillation, and remove low boilers to obtain low hydrogen silicone oil with proper hydrogen content;

[0043] Add low-hydrogen silicone oil and D4 into the reaction kettle equipped with a stirrer, reflux condenser and thermometer in sequence at a ratio of 10:0.3, and stir with N2. After the temperature rises to 60°C, add heavy metal oxides, continue to stir, and react at a constant temperature of 110°C. After 3 hours, the reaction solution became turbid and clear;

[0044] Then add methyltriethoxysilane and allyl polypropylene glycol into the reaction kettle in sequence at 0.5:10, keep the material reaction until tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com