Preparation method of 1,4-dioxane

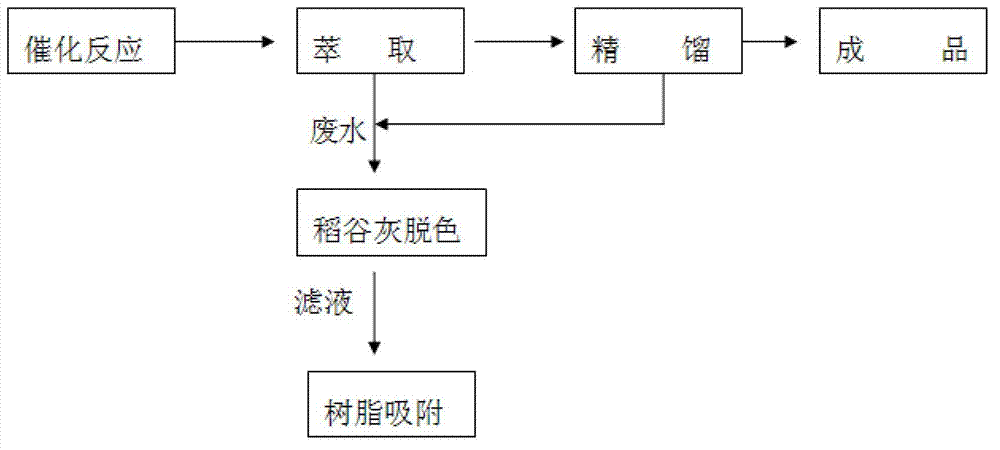

A technology of dioxane and diethylene glycol is applied in the field of preparation of 1,4-dioxane, which can solve the problems of difficult wastewater treatment, inability to realize continuous production of products, environmental pollution, etc. The utilization rate of equipment, the realization of long-term pollution-free production, and the effect of improving the extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] (1) Synthesis process: Preheat the synthesis tower with solid superacid resin to 115°C, transport diethylene glycol to the heater at a flow rate of 500Kg / h, and heat it to 120°C through steam or heat transfer oil. After heating, the two Glycol enters the preheated synthesis tower, and the feed liquid enters the vapor-liquid separator after passing through the synthesis tower. A small amount of unreacted feed liquid cools down and returns to the diethylene glycol raw material tank to continue the reaction. The vapor phase reaction products 1,4 -Dioxane and water enter the crude product receiving tank after condensation, go out crude product 410Kg / h, unreacted reflux diethylene glycol 90 Kg / h;

[0022] (2) Extraction process: the crude product enters the extraction tower from the upper distributor of the extraction tower at 405 Kg / h, and the extractant isopropyl ether enters the extraction tower from the lower distributor of the extraction tower at 150 Kg / h. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com