A material bottle cartoning machine and its cartoning process

A cartoning machine and bottle technology, which is applied in packaging, bottle packaging, transportation and packaging, etc., can solve the problems of slow packaging speed, low efficiency, large volume, etc., so as to reduce walking time, improve production efficiency, and reduce travel small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

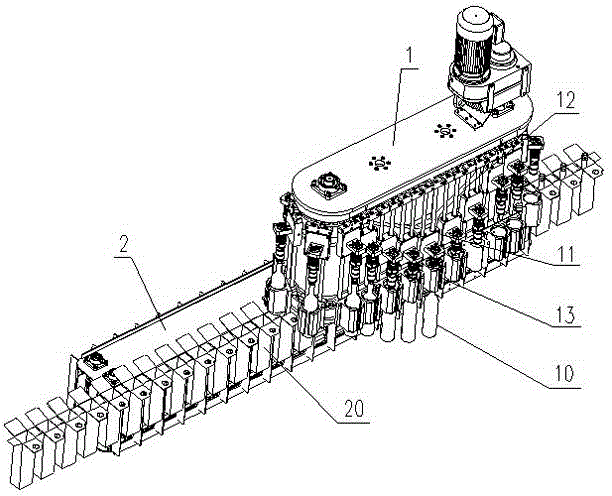

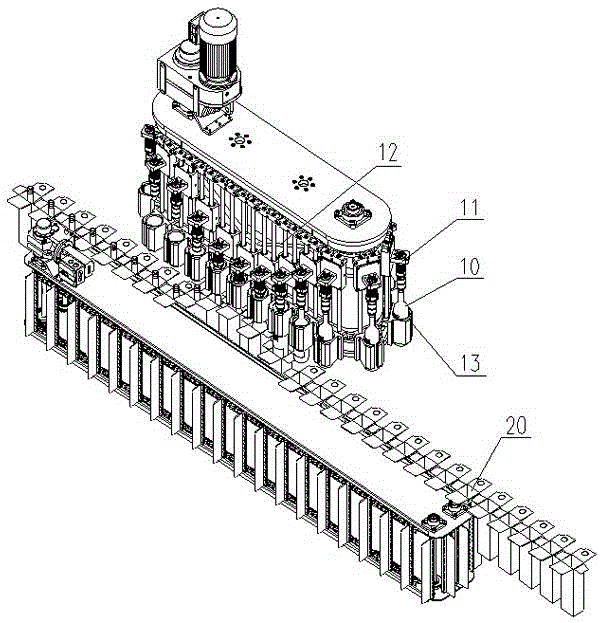

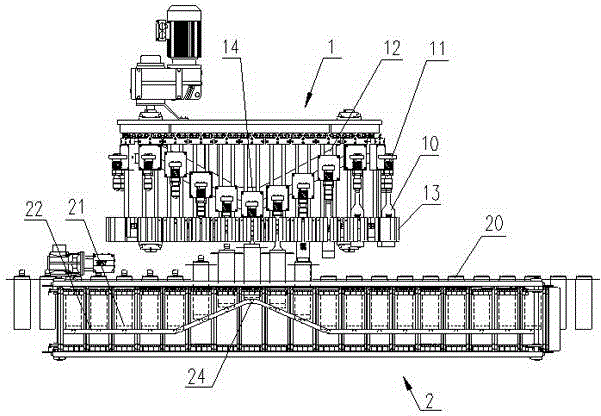

[0015] The material bottle cartoning machine of the present invention comprises a bottle conveying device 1 for conveying a material bottle 10 and a box conveying device 2 for conveying a packing box 20, the bottle conveying device 1 is provided with a bottle conveying fixture 11 for clamping a material bottle 10, and conveying The box device 2 is provided with a box delivery fixture 21 for clamping the packaging box 20; the bottle delivery device 1 is provided with a bottle delivery guide rail 12 for the movement of the bottle delivery fixture 11, and the box delivery device 2 is provided with a delivery box for the movement of the box delivery fixture 21. Guide rail 22; One section of the bottle guide rail 12 is a curve convex to the box guide rail 22, and one section of the box guide rail 22 is a curve convex to the bottle guide rail 12, and the box guide rail 22 is located below the bottle guide rail 12, and The lowest point 14 of the curved section of the bottle guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com