Mineral coolie car

A rail car and mine-used technology, which is applied to railway car body components, hydrostatic brakes, hydrodynamic brakes, etc., can solve the problems of high installation accuracy, inability to use each other, and difficulty in realization, achieving high safety factor, Ensure production safety and overcome the high cost of track installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

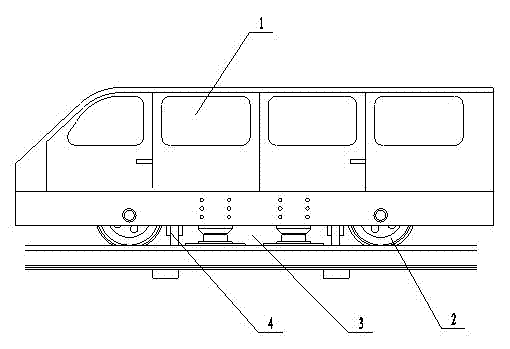

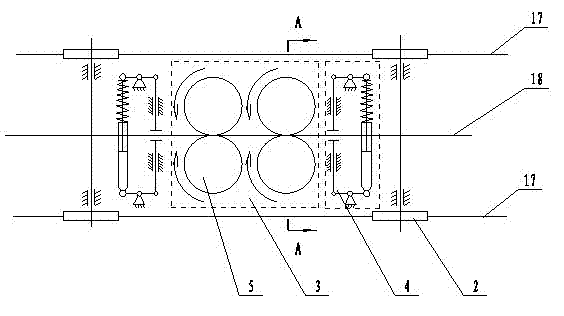

[0025] Such as Figure 1 to Figure 6 As shown, the mining rail car of the present invention includes a vehicle body 1, a driving device 3, a braking device 4, a track wheel set 2, a parallel track 17 and a special track 18, and the four or more track wheel sets 2 are installed It is on both sides of the bottom of the vehicle body 1 and is used to support the vehicle body 1 to run on parallel rails 17 .

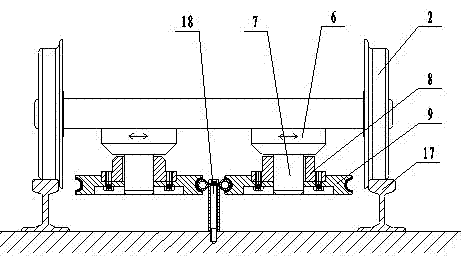

[0026] The driving device 3 includes a plurality of driving assemblies 5, and the driving assemblies 5 are horizontally installed in two rows in two rows on the bottom bracket of the vehicle body 1, and each of the driving assemblies 5 is mainly composed of a driving motor 6, a supporting wheel 8 and a driving wheel 9, the supporting wheel 8 is fixedly connected to the driving wheel 9 and then fastened and set on the output shaft 7 of the driving motor 6, and the driving motor 6 is vertically fixed on the bottom bracket of the vehicle body 1.

[0027] The brake device 4 is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com