Cylindrical paper tube opposition cutting machine

A cylindrical paper and extension technology, which is applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of low efficiency, scrapped cylindrical paper tubes, time-consuming and laborious, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

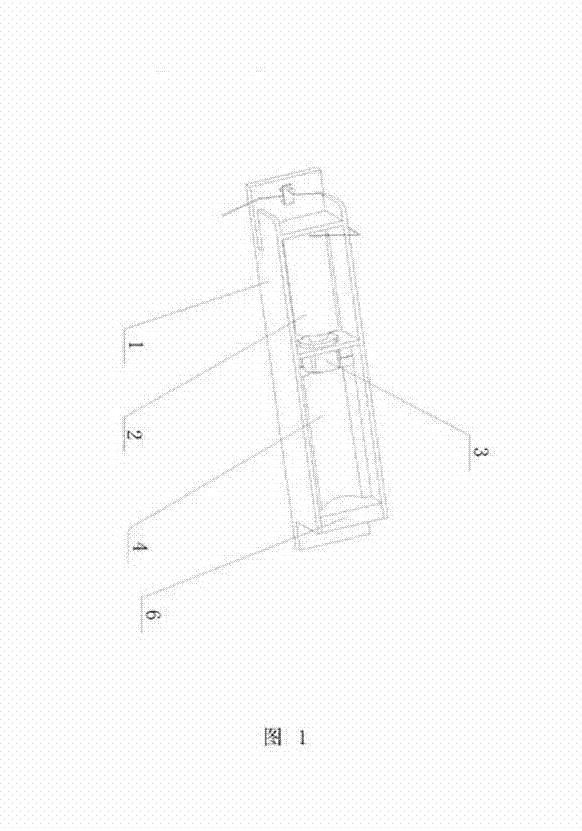

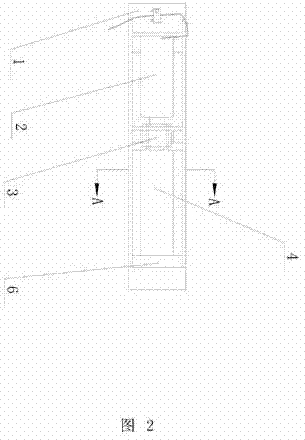

[0023] Such as Figure 1 to Figure 6 Shown, a kind of cylindrical paper tube splitting machine of the present invention is characterized in that: it comprises housing 1; The cylinder 2 that is fixed on the housing 1 and the cutting device 3 that is installed on the free end of piston rod of cylinder 2; It also comprises A cavity 4 for placing a cylindrical paper tube; the cavity 4 is provided with a guide device for the cutting device 3; the axis of the piston rod is on the same line as the axis of the cavity 4; the cavity 4 The rear end is equipped with an axial limit device for the cylindrical paper tube.

[0024] The cutting device 3 is detachably connected to the piston rod of the cylinder 2 .

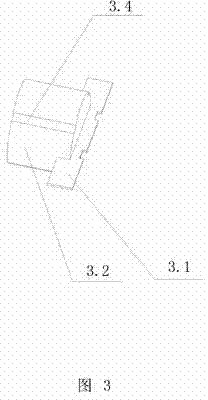

[0025] The cutting device 3 is composed of a cutting knife 3.1 and a cylinder 3.3 or cylinder 3.2 for fixing the cutting knife 3.1.

[0026] The cutting knife 3.1 is fixed on the front end of the cylinder 3.3 or the cylinder 3.2; the cutting knife 3.1 extends radially to both sid...

Embodiment 2

[0034] Such as Figure 1 to Figure 6 Shown, a kind of cylindrical paper tube splitting machine of the present invention is characterized in that: it comprises housing 1; The cylinder 2 that is fixed on the housing 1 and the cutting device 3 that is installed on the free end of piston rod of cylinder 2; It also comprises A cavity 4 for placing a cylindrical paper tube; the cavity 4 is provided with a guide device for the cutting device 3; the axis of the piston rod is on the same line as the axis of the cavity 4; the cavity 4 The rear end is equipped with an axial limit device for the cylindrical paper tube.

[0035] The cutting device 3 is detachably connected to the piston rod of the cylinder 2 .

[0036] The cutting device 3 is composed of a cutting knife 3.1 and a cylinder 3.3 or cylinder 3.2 for fixing the cutting knife 3.1.

[0037] The cutting knife 3.1 is fixed on the front end of the cylinder 3.3 or the cylinder 3.2; the cutting knife 3.1 extends radially to both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com