Numerical control machine error identification and separation method based on processing workpiece curved surface morphology information

A technology for processing workpieces and CNC machine tools, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc. It can solve the problems of difficulty in guaranteeing processing accuracy, inability to predict, and lack of machine tool error separation technology to achieve error compensation Reliable and effective work, achieve the effect of error separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

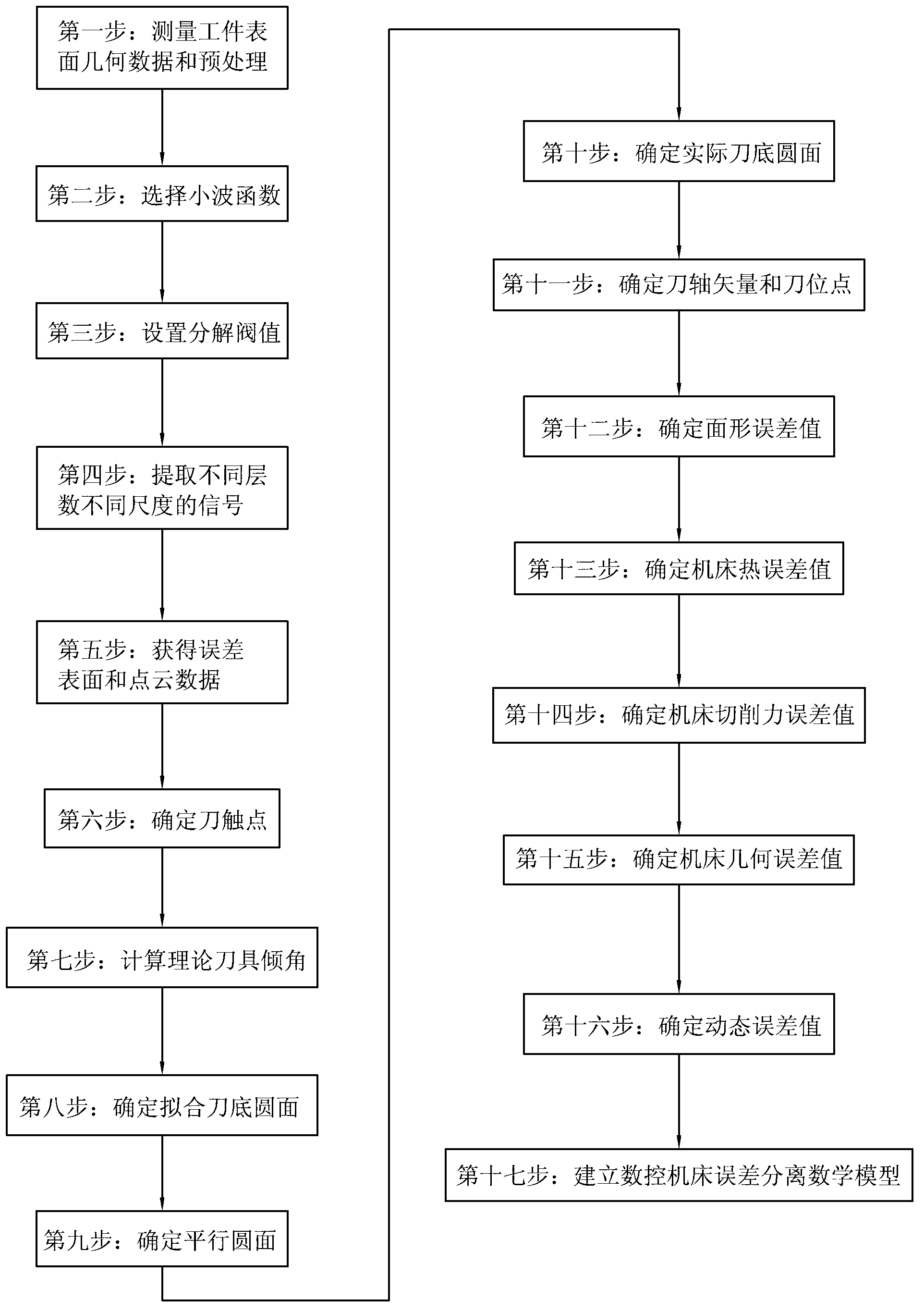

[0038] The CNC machine tool error identification and separation method based on the surface shape information of the processed workpiece is used to separate the processing errors in the process of processing the workpiece by the CNC machine tool. The specific steps of the method are:

[0039] Step 1: Take a processed workpiece, measure and preprocess the geometric data on the surface of the workpiece.

[0040] The second step: according to the properties of self-similarity, orthogonality and compact support, select a suitable function from dozens of commonly used wavelet functions, determine the length of support, and determine the best wavelet function through comparative analysis.

[0041] Step 3: Set the decomposition thresholds for different error signals.

[0042] Step 4: Decompose the data, determine the number of wavelet decomposition layers according to the different frequency domains of different component errors, and extract signals of different scales for different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com