Mould structure for centering molding process of rotating shaft symmetrical part

A technology of symmetrical parts and rotary shafts, applied in the field of mold structure, can solve the problems that the productivity and product quality cannot be further improved, and the casting process cannot be further developed and applied, so as to achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

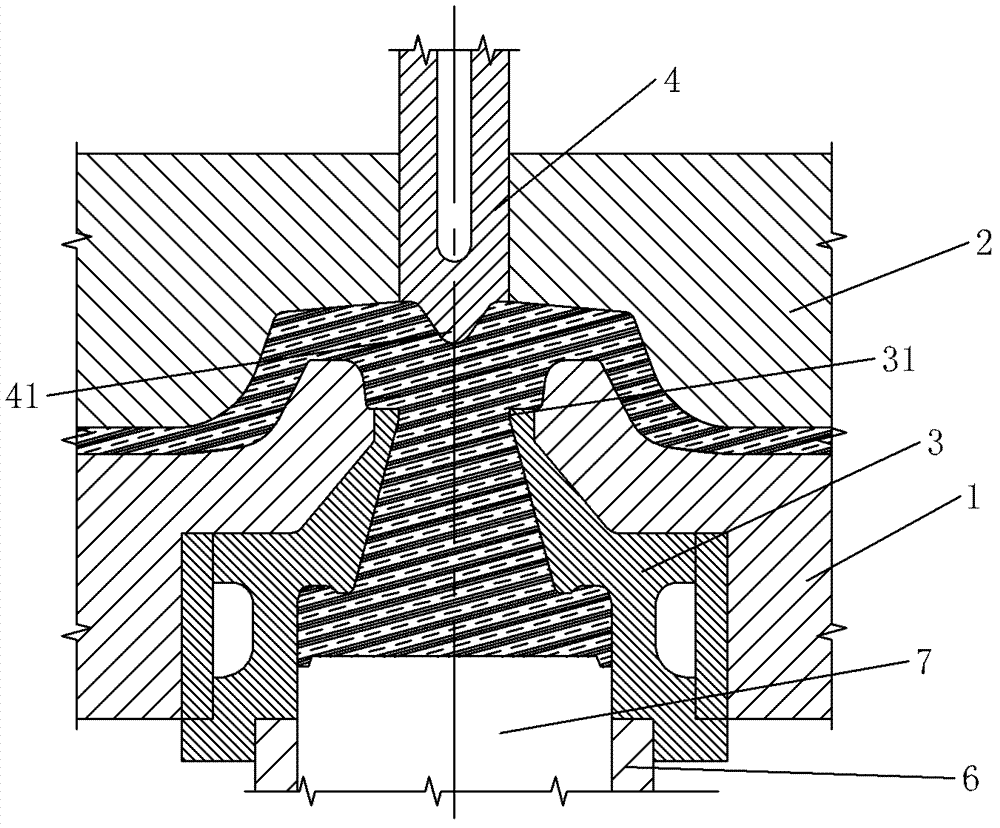

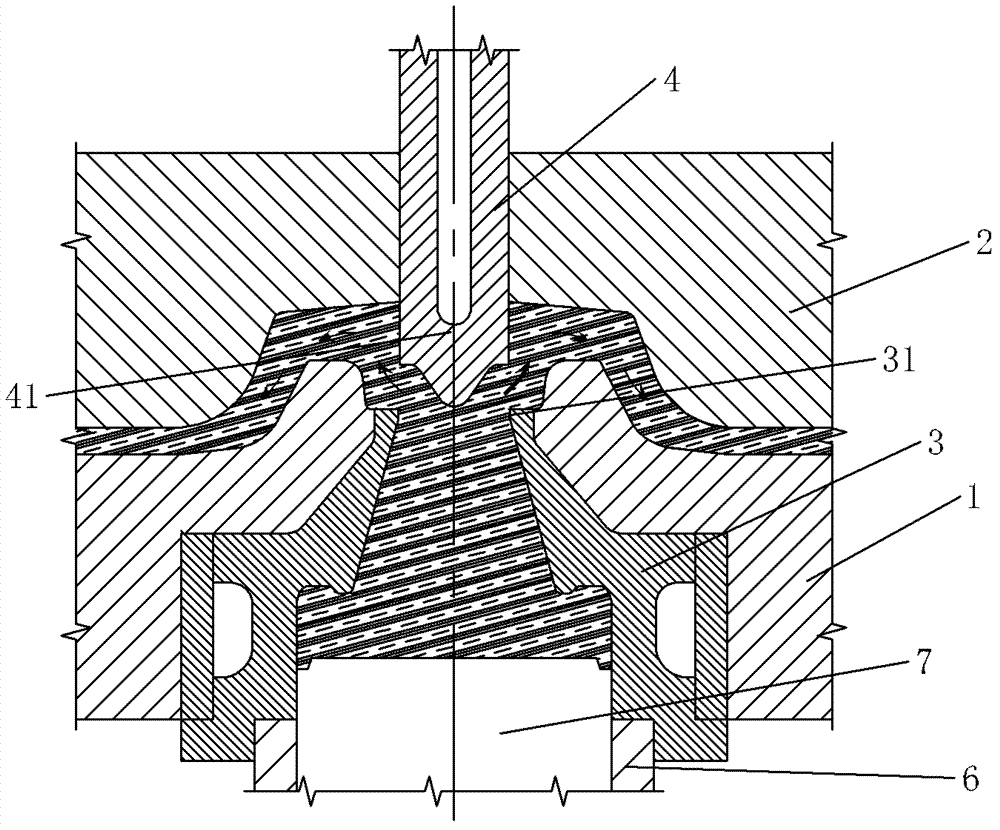

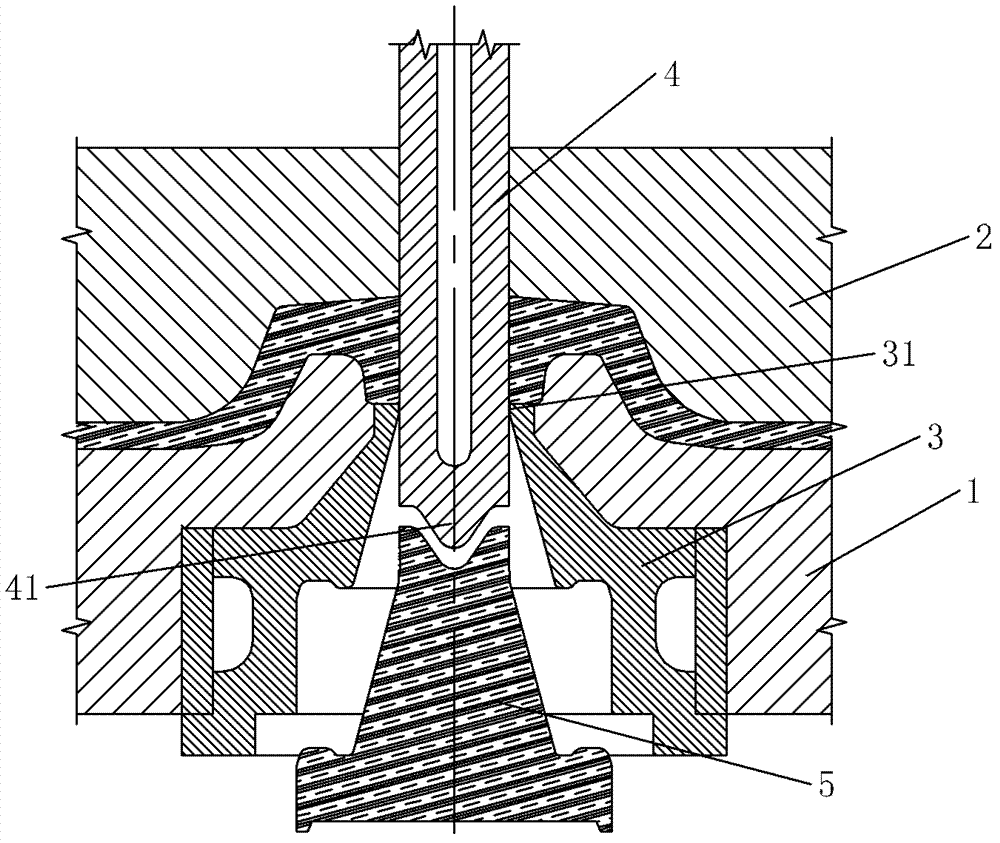

[0017] Such as Figures 1 to 3 As shown, a mold structure for the central casting process of a rotary axis symmetric part according to the present invention includes a fixed mold 1 and a movable mold 2, and a cavity is formed between the fixed mold 1 and the movable mold 2, and its specific The structure is as follows:

[0018] The fixed mold 1 is located at the center of the cavity and is provided with a sprue bushing 3 communicating with the cavity. The sprue bushing 3 is a large sprue bushing, and the diameter of the inner orifice 31 corresponds to the diameter of the center hole of the product. The inner cavity of the sprue bushing 3 is a tapered structure.

[0019] The movable mold 2 is located at the center of the cavity and is provided with a secondary extrusion rod 4 inserted on the movable mold 2 and connected with external extrusion power equipment; The shaft is set, and its head cooperates with the inner orifice 31 of the sprue sleeve to form a gate incision struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com