Glass fiber loading cuprous oxide visible light catalyst and application thereof

A glass fiber and cuprous oxide technology is applied in the field of photocatalysis, which can solve the problems of incompatibility and small specific surface area of glass slides, and achieve the effects of uniform loading, high practical value and improving catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 5 grams of glass fiber with a nominal diameter of 24 microns that has been cleaned and dried with detergent, distilled water and ethanol. Add 40 grams of 1 mol / L glucose aqueous solution to a beaker containing 20 grams of 1 mol / L copper nitrate aqueous solution, and stir to obtain a colorless and transparent solution. Place a beaker containing 200 grams of 1mol / L NaOH solution in a constant temperature water bath at 50 °C. Soak the glass fiber in the above colorless and transparent solution for 30 seconds, then take out the glass fiber and soak it in a NaOH solution at 50°C for 30 seconds, then take out the glass fiber and soak and rinse it in 300 grams of distilled water for 10 seconds. The above process is cycled 20 times, soaked in 95% ethanol solution for 30 seconds to remove water, and the glass fiber is dried at 65 °C to obtain the loaded golden yellow Cu 2 O film glass fiber. Cu 2 The O load rate is 2.85%.

[0024] The rest of the conditions are the same as ...

Embodiment 2

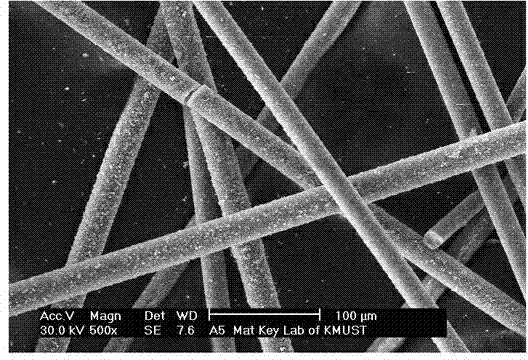

[0031] Weigh 5 grams of glass fiber with a nominal diameter of 24 microns that has been cleaned and dried with detergent, distilled water and ethanol. With 20 grams of 1 mol / L CuSO 4 Add 40 grams of 1mol / L Na in the beaker of the solution 2 S 2 O 3 The solution is stirred to obtain a colorless and transparent solution. Place a beaker containing 200 grams of 1mol / L NaOH solution in a constant temperature water bath at 50 °C. Soak the glass fiber in the above colorless and transparent solution for 30 seconds, then take out the glass fiber and soak it in a NaOH solution at 60°C for 30 seconds, then take out the glass fiber and soak and rinse in distilled water for 10 seconds. The above process is cycled 20 times, soaked in 95% ethanol solution for 30 seconds to remove water, and the glass fiber is dried at 62 °C to obtain a golden yellow Cu 2 O film glass fiber. Cu 2 The O load rate is 4.01%. The glass fiber prepared in this embodiment supports Cu 2 O SEM picture see figure 1 ....

Embodiment 3

[0036] Weigh 5 grams of glass fibers with a nominal diameter of 30 microns that have been cleaned and dried with detergent, distilled water and ethanol. Add 40 grams of 1 mol / L hydroxylamine hydrochloride aqueous solution to a beaker containing 20 grams of 1 mol / L copper acetate solution and stir to obtain a colorless and transparent solution. Place a beaker containing 200 grams of 1mol / L NaOH solution in a constant temperature water bath at 50 °C. Soak the glass fiber in the above colorless and transparent solution for 30 seconds, then take out the glass fiber and soak it in the NaOH solution at 65°C for 30 seconds, then take out the glass fiber and soak and rinse in distilled water for 10 seconds. The above process is cycled 20 times, soaked in 95% ethanol solution for 30 seconds to remove water, and the glass fiber is dried at 67 °C to obtain the loaded golden yellow Cu 2 O film glass fiber. Cu 2 The O load ratio is 3.91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com