Roller-cutter type plant stalk pulverizer

A plant straw and pulverizer technology, applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve the problems of waste of resources, strict requirements on straw moisture, low work efficiency, etc., and achieve reasonable structure design and convenient field operation. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

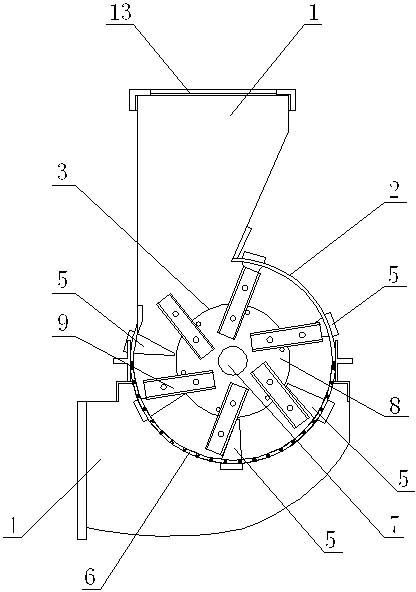

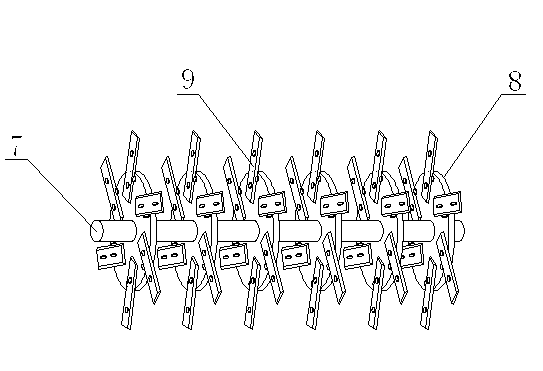

[0015] The roller knife type plant straw grinder of the present invention is composed of a feed hopper 1, a crushing bin 2, a roller knife 3 and a discharge port 4. The upper part of the crushing bin 2 is open, and the feeding hopper 1 is connected to the crushing bin 2. The shell below the axis of the crushing bin 2 is an arc-shaped sieve plate 6, and the periphery of the arc-surface sieve plate 6 is connected with a pipe body to form a discharge port 4. The crushing bin 2 is in the shape of a horizontal straight barrel, and a roller knife 3 is arranged axially in the barrel. The roller knife 3 is composed of a roller shaft 7, a knife holder 8 and a crushing knife 9, and the roller shaft 7 is provided with a knife holder 8 at intervals. , Each knife holder 8 is provided with more than one pulverizing knife 9, and the pulverizing knife 9 is cut with the fixed knife 5 fixed on the inner wall of the pulverizing chamber 2.

Embodiment 2

[0017] The roller knife type plant stalk pulverizer of the present invention is made of feed hopper 1, crushing bin 2, roller knife 3 and discharge port 4, and the upper part of crushing bin 2 is open, and the gap between feeding hopper 1 and crushing bin 2 The upper port is connected, and the feeding hopper 1 is provided with an upper cover 13 to prevent materials from splashing out. The housing below the axis of the crushing bin 2 is an arc-shaped sieve plate 6 , and the periphery of the arc-surface sieve plate 6 is connected with a pipe body to form a discharge port 4 . The crushing bin 2 is in the shape of a horizontal straight barrel, and a roller knife 3 is arranged axially in the barrel. The roller knife 3 is composed of a roller shaft 7, a knife holder 8 and a crushing knife 9. The roller shaft 7 is provided with more than one Knife rest 8, described knife rest 8 is disc-shaped, and on the circumference of each disc-shaped knife rest 8, more than one pulverizing knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com