Two engine system with a gaseous fuel stored in liquefied form

A gaseous fuel, twin-engine technology, applied in the field of twin-engine systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

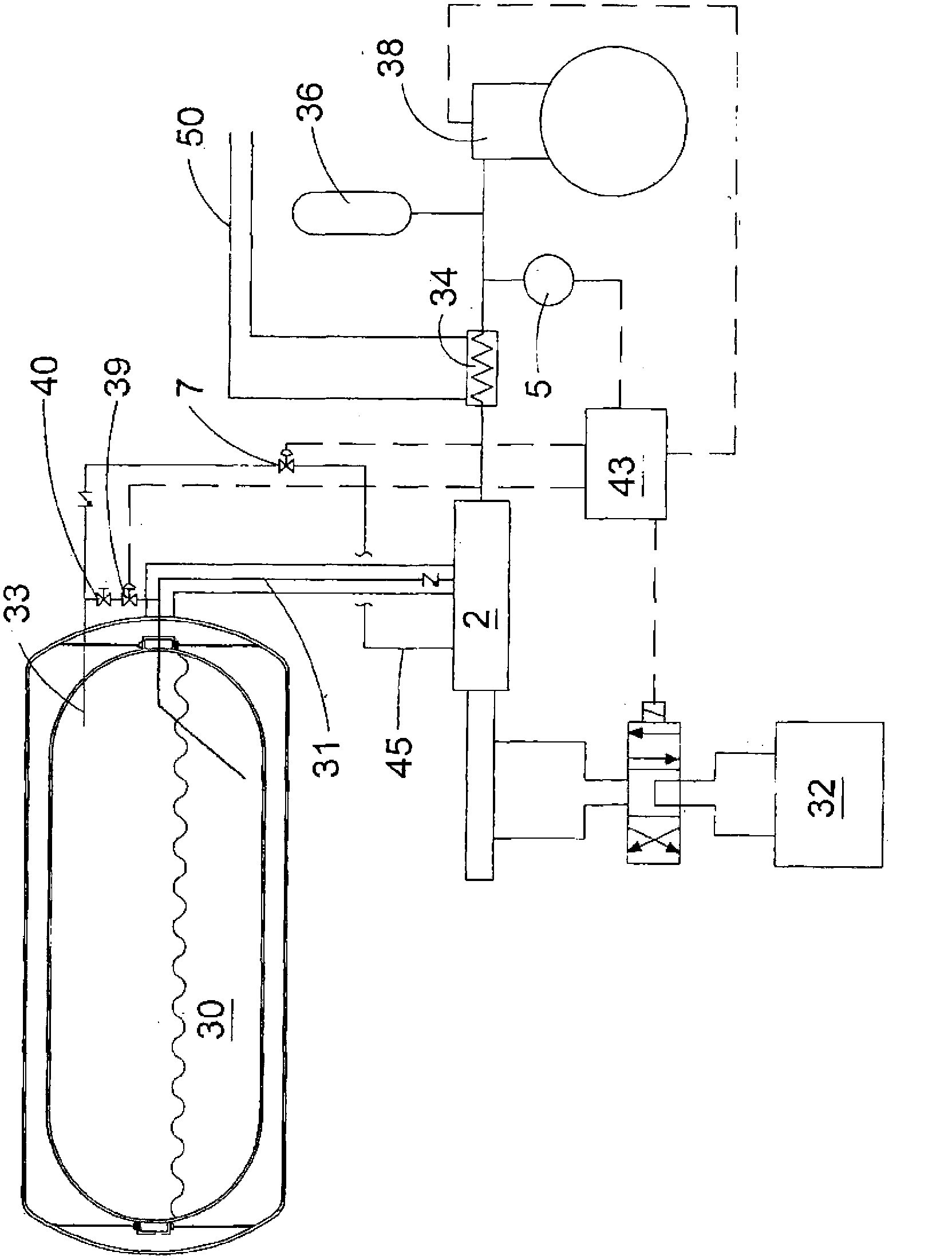

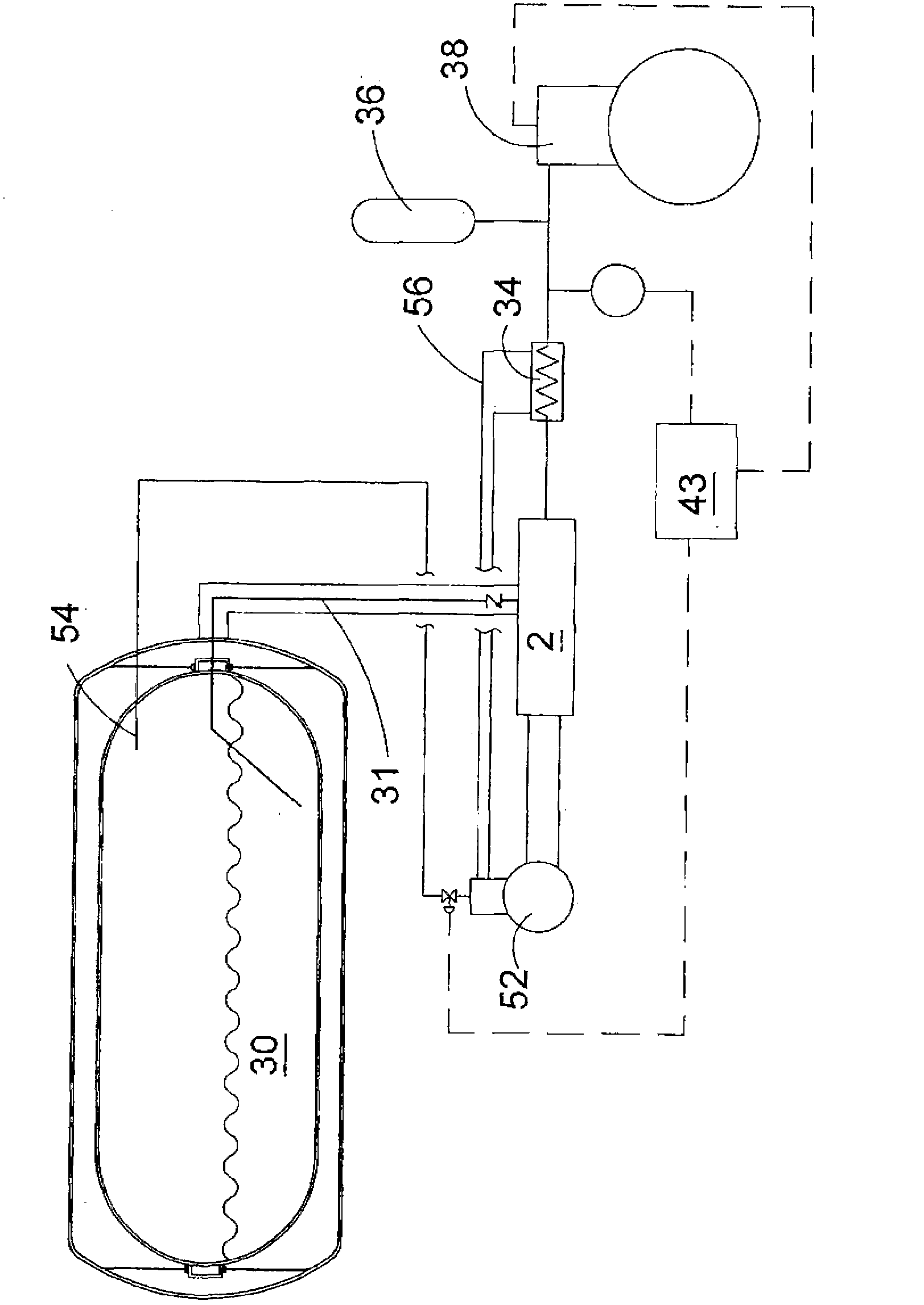

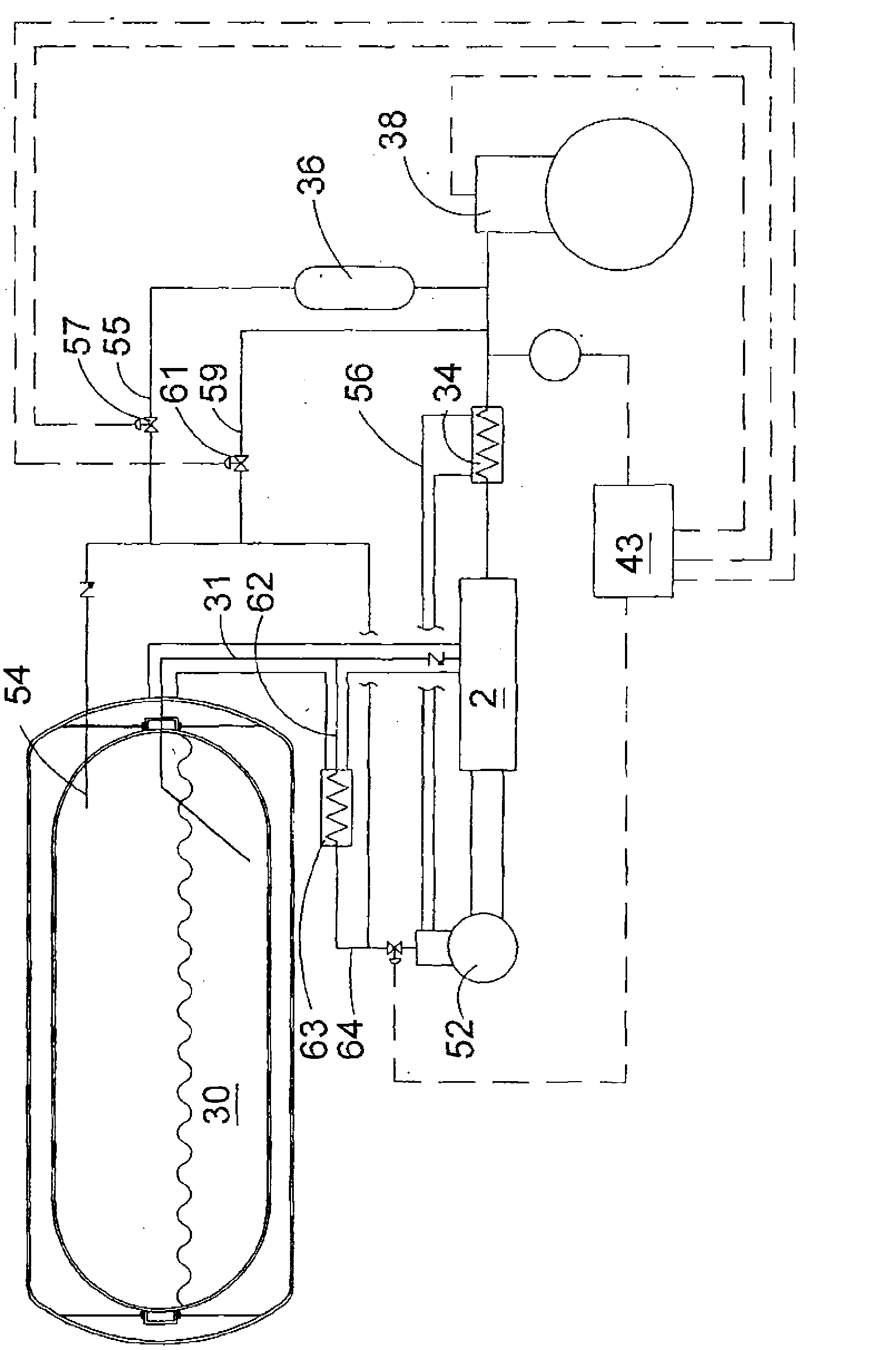

[0020] The disclosed twin engine system includes a fuel injected HPDI internal combustion engine for motoring purposes, wherein the fuel injected HPDI internal combustion engine is fueled by gaseous fuel stored on board the vehicle in liquid form. The fuel supply system converts the stored liquid gas into gaseous form and delivers it at injection pressure for direct injection into the combustion chamber of the HPDI internal combustion engine. For example, if the liquid gaseous fuel is natural gas, the storage pressure between about -130 degrees Celsius and -160 degrees Celsius is typically less than about 10 bar. Injection pressures for HPDI internal combustion engines are typically at least 200 bar. In a typical system, the pressure relief valve can be set at approximately 17 bar (approximately 250 psi). According to the disclosed system, a separate auxiliary fumigation internal combustion engine, also fueled by gaseous fuel, is used to drive the cryopump in the fuel supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com