Preparation method of magnesium alloy wire based on severe plastic deformation

A technology of severe plastic deformation and magnesium alloy, which is applied in the field of magnesium alloy wire drawing and preparation, to achieve the effect of reducing energy consumption, excellent comprehensive mechanical properties, and improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] AZ31 magnesium alloy was used for wire preparation, and its composition was Al 3.0wt%, Zn 1.0wt%, Mn 0.2wt%, and the rest was Mg and unavoidable impurities. Specific steps are as follows:

[0026] (a) After mixing the alloy raw materials in 0.1at% SF 6 +CO 2 Melting is carried out under the protection of mixed gas. After the raw materials are completely melted, they are cast at 680°C in a circular pure copper water-cooled mold with an inner diameter of Φ30mm;

[0027] (b) Hot-extrude the ingot at 300°C into a thin round bar of Φ5mm, the extrusion ratio is 36, and the extrusion speed is 20mm / s;

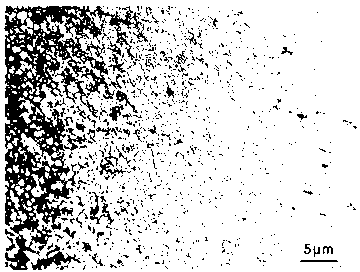

[0028] (c) Cut the extruded round bar into sections with a length greater than 150mm, and then put it into an equal-channel angular extrusion die with a channel angle of 90° and no arc at the corner, and perform 8 passes of angular extrusion at 200°C , the extrusion speed is 5mm / s. After each round of equal-channel angular extrusion, the extruded bar is rotated 90° in the sam...

Embodiment 2

[0033] Prepare Mg-Al alloy, its composition is Al 2.5wt%, Zn 0.5wt%, Mn 0.5wt%, the rest is Mg and unavoidable impurities.

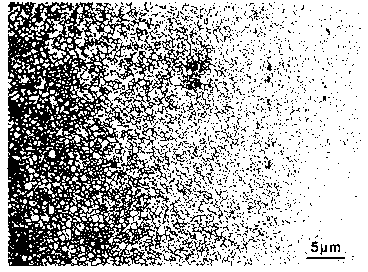

[0034] The process method of this example is different from Example 1. In step (a), the molten alloy is cast into a Φ20mm round rod ingot at a casting temperature of 700°C; in step (b), the ingot is extruded at 360°C into a Φ5mm ingot. Thin round bar, the extrusion ratio is 16, and the extrusion speed is 25mm / s; in step (c), put the cut extruded bar into an equal-channel corner extrusion die with a channel angle of 90° and a corner arc of 30°C Inside, 6 passes of angular extrusion were carried out at 300°C, and the extrusion speed was 2mm / s; in step (d), the equal-channel extruded rod was subjected to room temperature dry drawing, and the drawing speed of each pass was controlled at 60mm / s, the reduction of area of the adjacent pass is 13.1±1%, when the multi-pass drawing reaches the cumulative reduction of area of 67.5±1%, the intermediate annealin...

Embodiment 3

[0037] The Mg-Al alloy is prepared, its composition is Al 6.5wt%, Zn 1.5wt%, Mn 1.0wt%, the rest is Mg and unavoidable impurities.

[0038] The difference between the process method of this example and Example 1 is that in step (a) the raw materials to be prepared are completely melted and the alloy melt is cast into a Φ32mm round rod ingot at 720°C; in step (b) the ingot is extruded at 340°C Press a thin round bar with a diameter of Φ8mm, the extrusion ratio is 16, and the extrusion speed is 30mm / s; in step (c), put the cut extruded rod into an equal channel with a channel angle of 90° and a corner arc of 20°C In the corner extrusion die, 4 passes of corner extrusion were carried out at 260°C, and the extrusion speed was 3mm / s; The speed is controlled at 60~65mm / s, and the area reduction rate of adjacent passes is 12.6±1%. When the multi-pass drawing reaches the cumulative area reduction rate of 65.8±1%, intermediate annealing is performed, and the annealing temperature is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com