Dielectric rubber body for packaging sensor and radio-communication system taking dielectric rubber body as carrier

A radio communication, rubber body technology, applied in transportation and packaging, other chemical processes, chemical instruments and methods, etc., to achieve the effect of high elasticity, firm connection, and stable data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

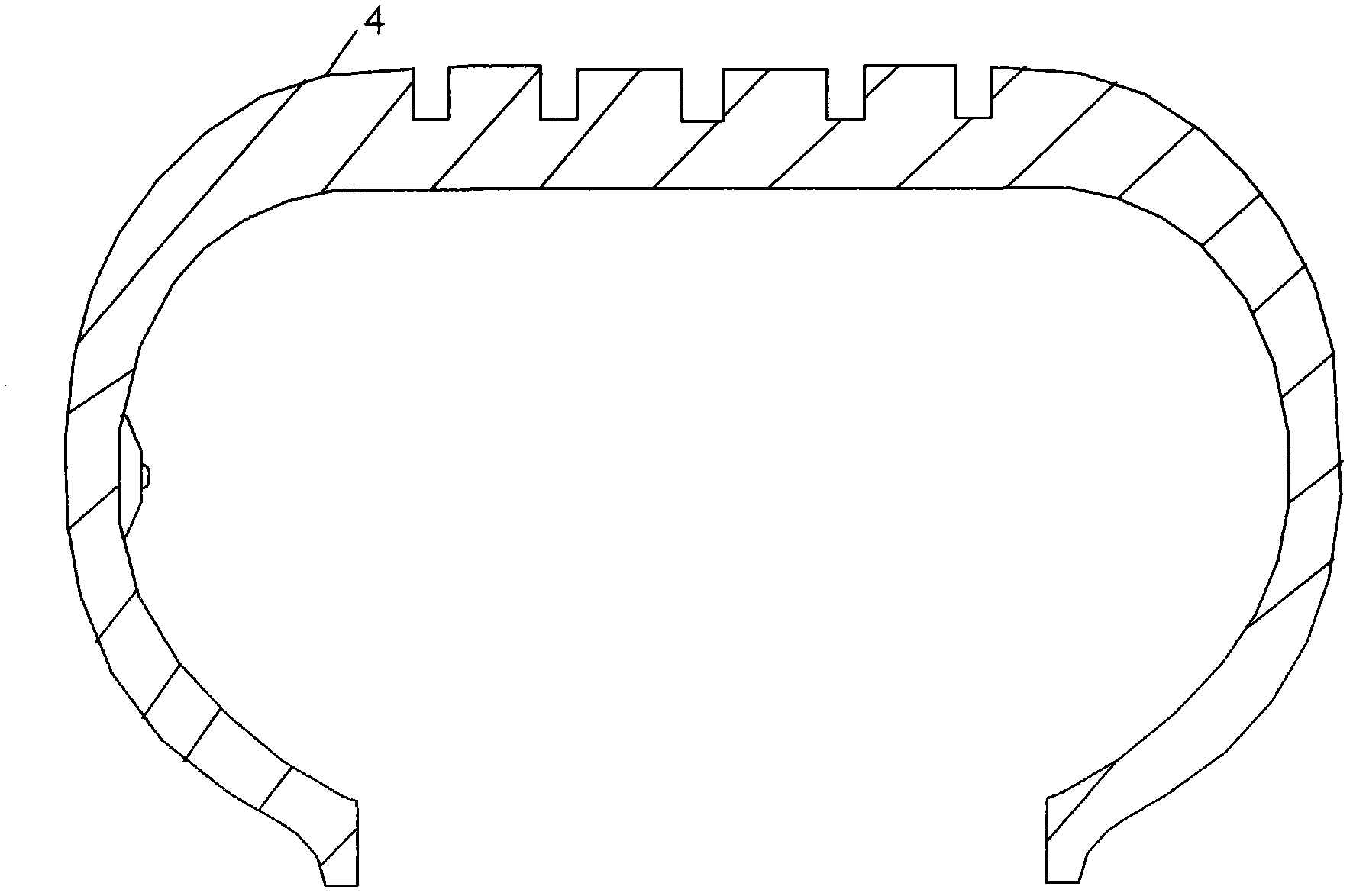

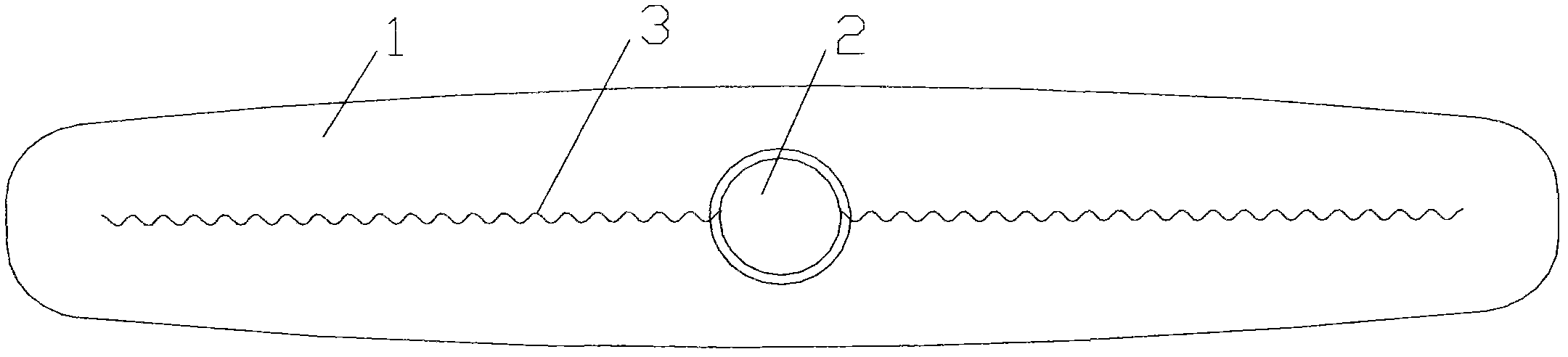

[0018] A dielectric rubber body for encapsulating sensors, the formula of the dielectric rubber body is as follows:

[0019]

[0020] The rubber mixing process is divided into two stages of mixing production. Add raw rubber (including: chlorinated butyl rubber, styrene-butadiene rubber, natural rubber), light calcium carbonate, carbon black, stearic acid, magnesium oxide, phenolic tackifying resin (code name 203) materials to one section of the rubber compound formula, and the rest The compounding agent is added in the two-stage feeding formula. The rubber material of the first stage is mixed and manufactured in the GK400N internal mixer; the rubber material of the second stage is manufactured in the internal mixer, and the rubber material is pounded on the tablet machine for three rounds, and then the tablet is cooled and parked. The rubber material in the section can only enter the next processing step after it has been parked for 4 hours.

[0021] The principle of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com