High flame resistance and high heat resistant synthetic rubber and preparation method thereof

A synthetic rubber, high heat-resistant technology, applied in the field of materials to reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

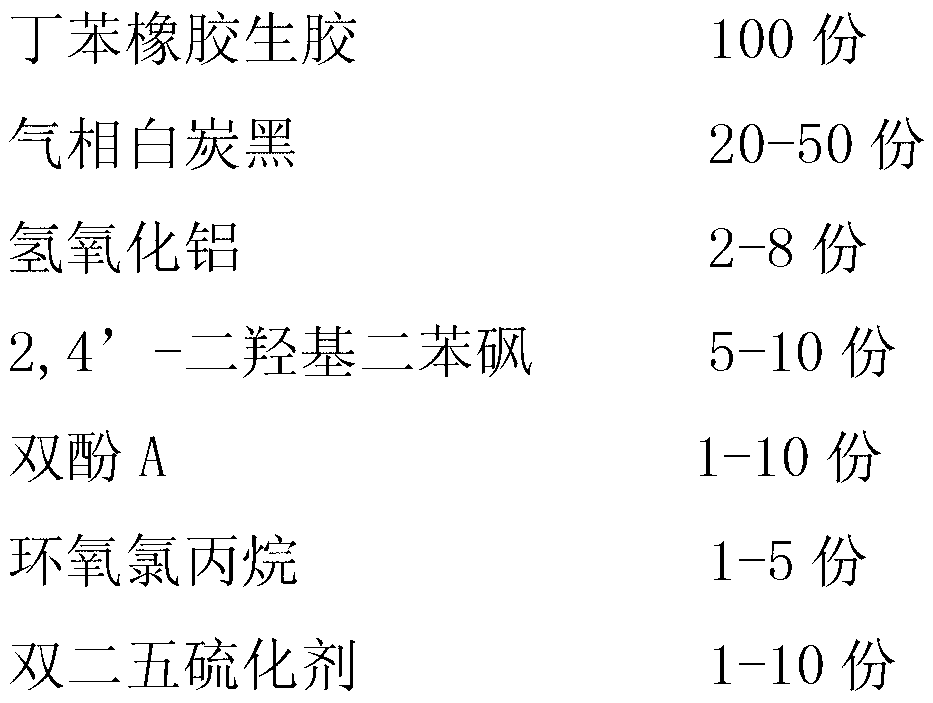

Method used

Image

Examples

Embodiment 1

[0017] (1) Weigh 100 parts by weight of styrene-butadiene rubber raw rubber, 20 parts by weight of fumed silica, and 5 parts by weight of 2,4'-dihydroxydiphenylsulfone into a mixer for 0.3 hours;

[0018] (2) Then add 2 parts by weight of aluminum hydroxide, 1 part by weight of bisphenol A and 1 part by weight of epichlorohydrin and continue mixing for 1 hour;

[0019] (3) Add 1 part by weight of bis-pentasulfurizing agent, and raise the temperature to 190°C for vulcanization;

[0020] (4) The finished product is obtained after vulcanization for 2 hours.

[0021] The parts not mentioned are conventional operation methods.

Embodiment 2

[0023] (1) Weigh 100 parts by weight of styrene-butadiene rubber raw rubber, 50 parts by weight of fumed silica, and 10 parts by weight of 2,4'-dihydroxydiphenyl sulfone into a mixer and knead for 0.8 hours;

[0024] (2) Then add 8 parts by weight of aluminum hydroxide, 7 parts by weight of bisphenol A and 3 parts by weight of epichlorohydrin and continue mixing for 2 hours;

[0025] (3) adding 10 parts by weight of bis-pentasulfurizing agent, rising to a temperature of 215°C for vulcanization;

[0026] (4) The finished product is obtained after vulcanization for 3 hours.

[0027] The parts not mentioned are conventional operation methods.

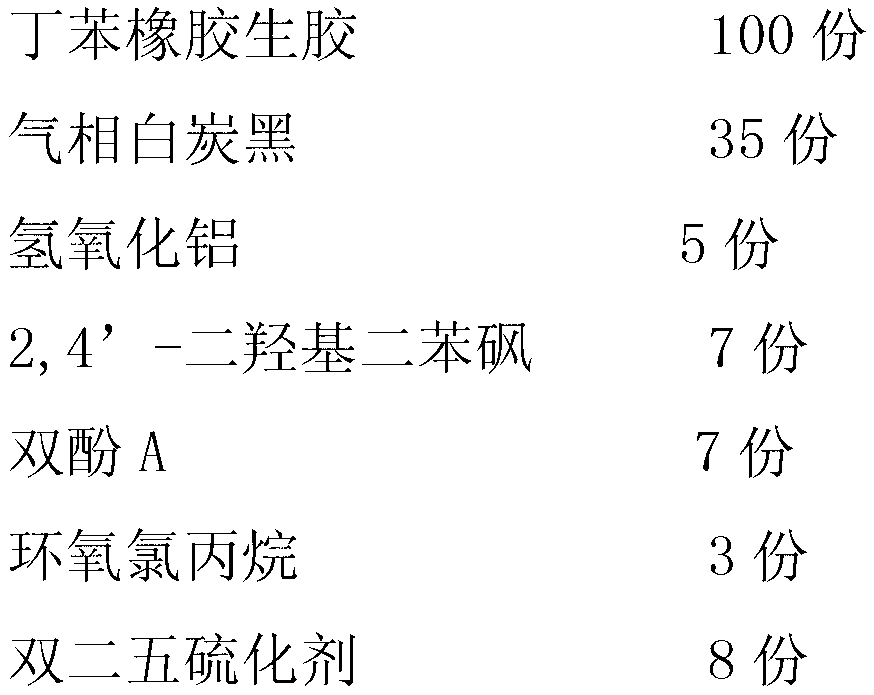

Embodiment 3

[0029] (1) Weigh 100 parts by weight of styrene-butadiene rubber raw rubber, 30 parts by weight of fumed silica, and 7 parts by weight of 2,4'-dihydroxydiphenyl sulfone into a mixer for 0.4 hours;

[0030] (2) Then add 6 parts by weight of aluminum hydroxide, 3 parts by weight of bisphenol A and 4 parts by weight of epichlorohydrin and continue mixing for 1 hour;

[0031] (3) Add 3 parts by weight of bis-pentasulfurizing agent, and rise to a temperature of 195° C. for vulcanization;

[0032] (4) The finished product is obtained after vulcanization for 1.5 hours.

[0033] The parts not mentioned are conventional operation methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com