Machining detection process for part

A technology of parts and technology, applied in the field of processing and testing technology of parts, can solve the problems such as the coating thickness does not meet the requirements of design drawings, and achieve the effect of improving processing quality, scientific technology and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

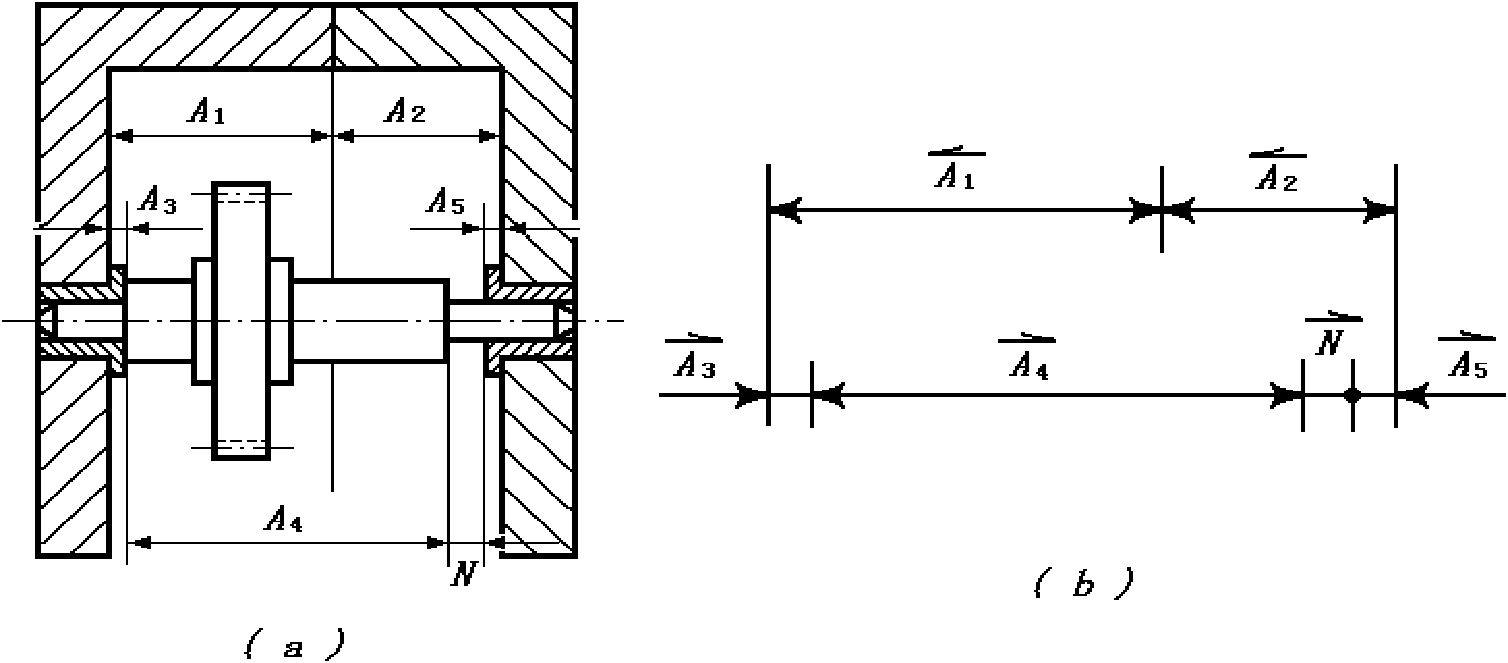

[0028] The traditional parts processing technology is: blanking - turning - heat treatment - electroplating. Due to the blindness of this kind of processing technology, the defective rate of the parts formed by the processing is relatively high. After the long-term accumulation of the inventor Based on the processing experience, the traditional parts processing technology is completely reformed. Through the calculation of the size chain, the process size of the production process is determined, and the parameters of the coating thickness of the parts are calculated, and the production process is strictly controlled in the production process to ensure the final product. Quality, parts formed by new processing technology have a high pass rate, and the precision has also been greatly improved.

[0029] The reformed processing technology includes the following steps:

[0030] Cutting—determining the size chain of parts—rough turning according to the size chain—heat treatment—fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com