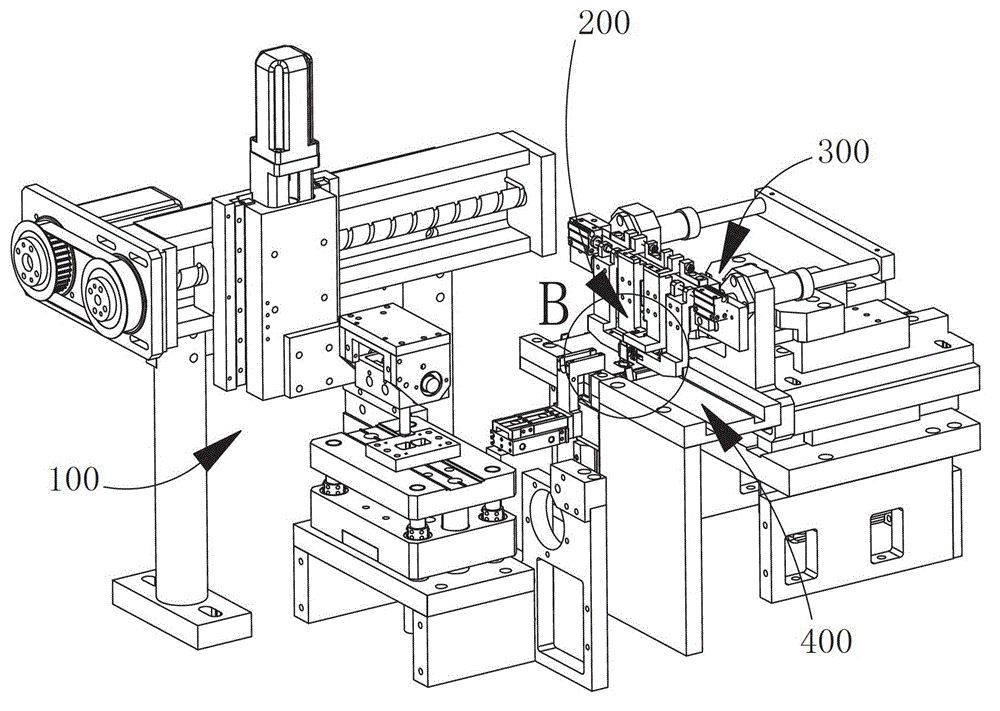

Chip welding method of dual-interface card and equipment thereof

A chip welding and dual-interface card technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of dual-interface cards that take a long time, affect the chip, and false soldering, and avoid collisions or vibrations. And false welding, reduce empty travel or inaccurate positioning, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

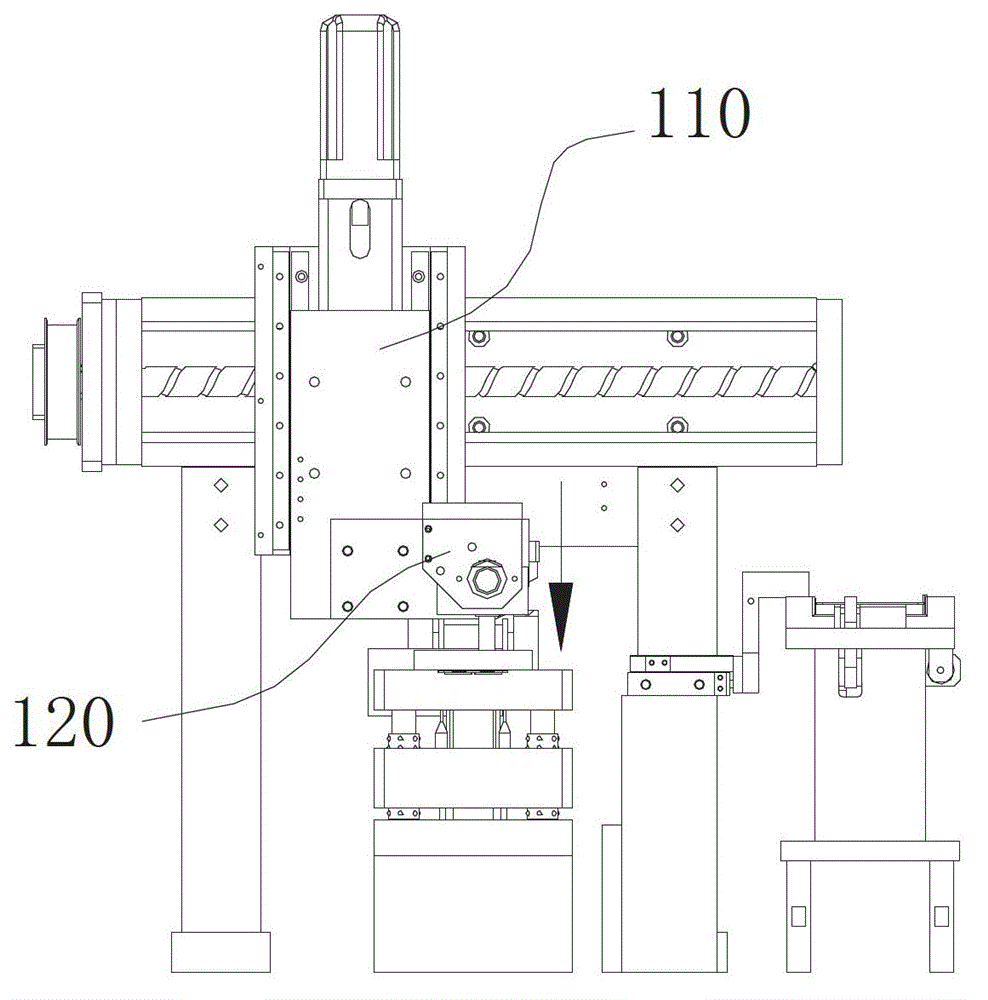

[0056] The following is a preferred specific implementation example of the present invention, a chip welding method for a dual-interface card, comprising the following steps:

[0057] Step 1, the card body reaches the position to be welded through the card body conveying device, and the two ends of the antenna of the card body are in the erected state; the chip pick-up device picks up the chip and arrives at the position to be welded;

[0058] Step 2, the clamping device simultaneously clamps both ends of the antenna and locates it at the welding position of the chip;

[0059] Step 3, the two ends of the positioned antenna are welded to the chip by the double-touch welding head;

[0060] Step 4, after the welding is completed, the double-touch welding head returns to its position, and then the clamping device loosens the clamping and positioning of the two ends of the antenna, and then the card body conveying device transports away the welded card body.

[0061] The second st...

Embodiment 2

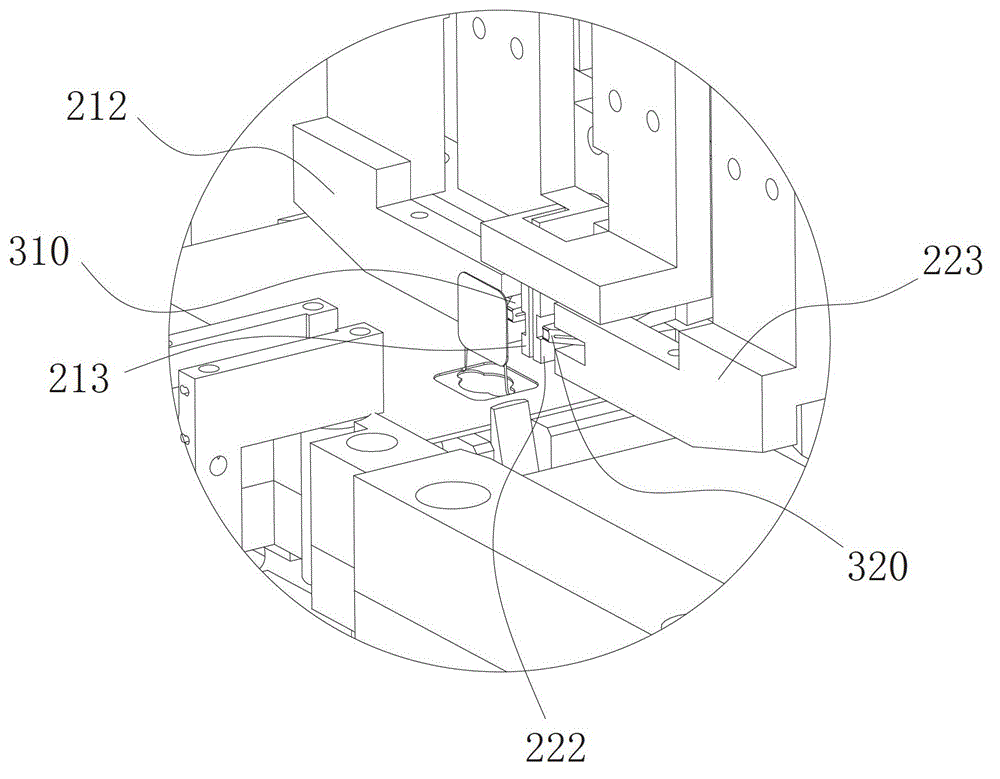

[0077] Such as Figure 18-26As shown, the difference between this preferred specific implementation example and Embodiment 1 lies in that: the two gripping fingers of the first grasping and positioning hand 210A are specifically the first gripping finger 212A and the second gripping finger 222A, and the second gripping The two clamp fingers of the positioning hand 220A are specifically the third clamp finger 213A and the fourth clamp finger 223A, and the first clamp finger 212A, the second clamp finger 222A, the third clamp finger 213A and the fourth clamp finger 223A are sequentially slidably connected to the On the backing plate 240, a spring is connected between the first clamping finger 212A and the fourth clamping finger 223A, and a spring is connected between the second clamping finger 222A and the third clamping finger 213A. The positioning hand driver 230 includes a slider 231A and a slider pneumatic part 232A installed between the first grasping and positioning hand 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com