Combined type boring bar device driven by giant magnetostrictive material for servo

A giant magnetostrictive, combined technology, applied in the direction of boring bars, parts of boring machines/drilling machines, drilling/drilling equipment, etc. requirements, quick replacement of boring bars and other problems, to achieve the effect of non-contact drive and control, simple structure and wide magnetic field range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

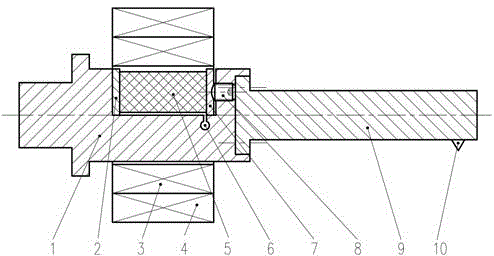

[0012] Such as figure 1 Shown, the present invention comprises cylindrical elastic deformation body 1, the first magnetic conduction block 2, the second magnetic conduction block 7, excitation mechanism, giant magnetostrictive material rod 5 and boring bar 9; One end of elastic deformation body 1 and The main shaft is connected by a flange, the other end of the elastic deformation body 1 is connected with one end of the boring bar 9, the other end of the boring bar 9 is equipped with a boring tool 10, the outer cylindrical surface of the elastic deformation body 1 is axially grooved, and the groove is equipped with There are giant magnetostrictive material rods 5, the first magnetic conduction block 2 and the second magnetic conduction block 7 are respectively embedded between the two ends of the giant magnetostrictive material rod 5 and the two sides of the groove, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com