Slag discharge device and slag discharge method for sand basin

A technology of grit chamber and slag discharge pipe, which is applied to the feeding/discharging device of the settling tank, etc., which can solve the problems of poor effect of slag skimming pipe and reducing the moisture content of discharged slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawings and examples.

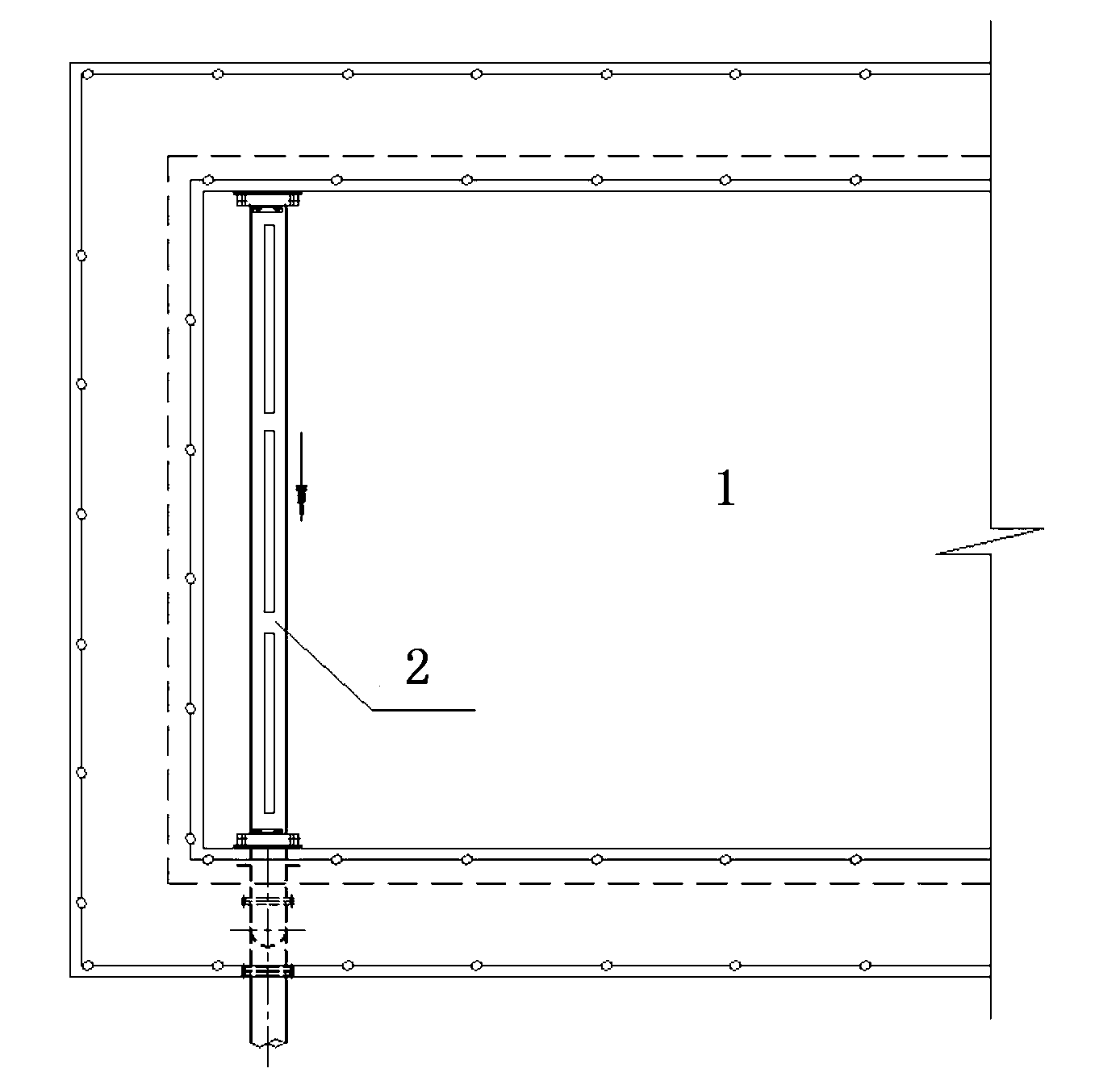

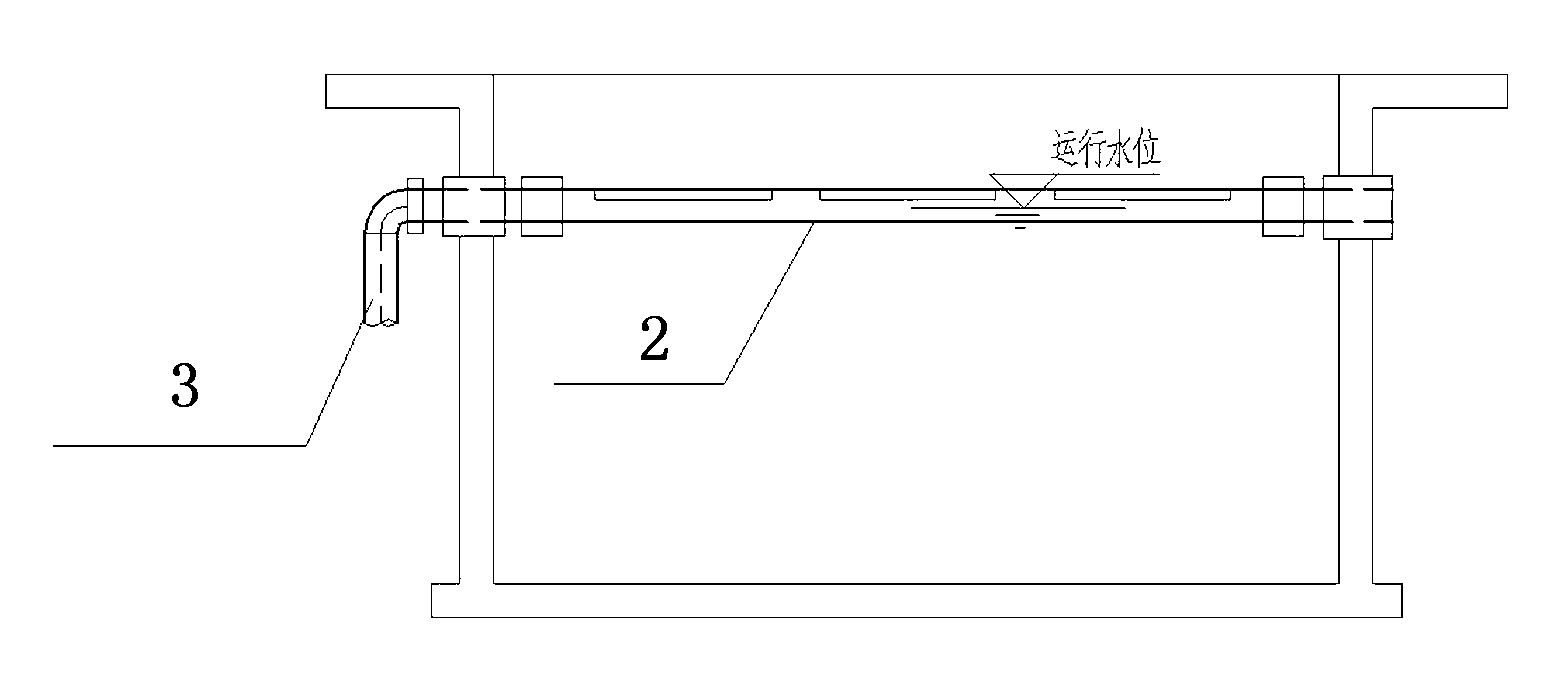

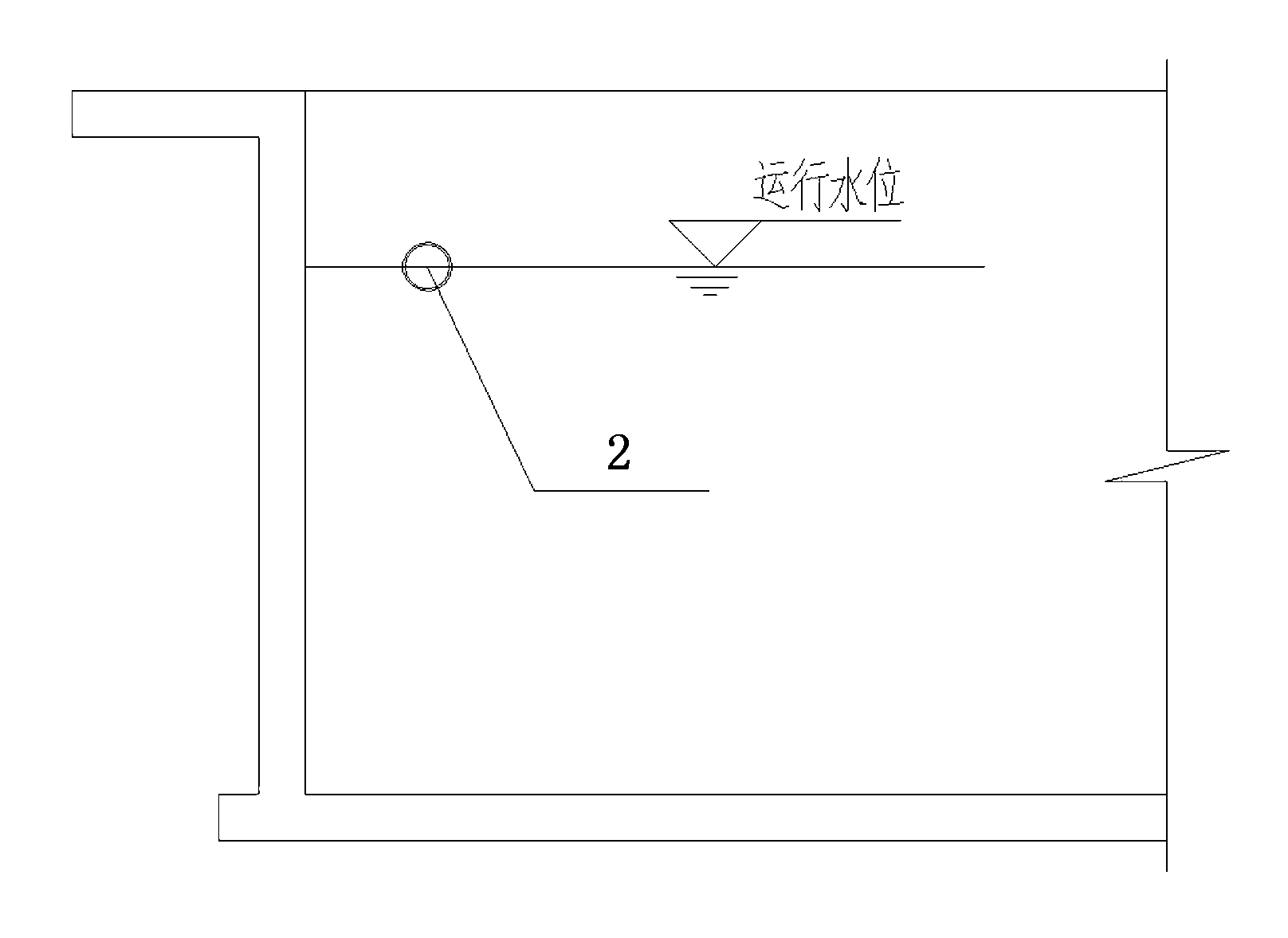

[0020] A kind of slag discharge method for grit chamber of the present invention is characterized in that a truss car type slag scraper 4 is arranged in the grit chamber 1, and a slag scraper 5 is arranged at the lower part of the truss car type slag scraper 4, and the grit chamber There is a slag discharge channel 6 in the pool, and an inclined slag scraping slope 7 is provided between the slag discharge channel 6 and the grit chamber 1. A screw conveyor press 8 is arranged in the slag discharge channel 6, and the output end of the screw conveyor press 8 is connected to the discharge port. The slag pipe 3 is connected. The slag discharge channel 6 is set at the end of the grit chamber 1, and the screw conveying press 8 in the slag discharge channel 6 is arranged obliquely, the outlet end is slightly higher, and the inclination angle is 1°-5°, and the slag dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com